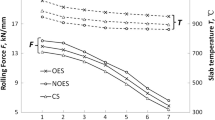

The most important properties of test Cr–Ni–Mo–V-steels, answering the main requirements specified for roll steels are studied: quenchability, hardenability, tempering stability, mechanical properties and impact strength, contact fatigue resistance. Dependences on roll cooling rate are determined for these properties. The Cr–Ni–Mo–V-steels with a carbon concentration of 0.50–0.85% developed on the basis of these studies are proposed for industrial approval.

Similar content being viewed by others

References

V. P. Polukhin, V. A. Nikolaev, M. A. Tylkin, et al., Reliability and Endurance of Cold Rolling Rolls [in Russian], Metallurgiya, Moscow (1976).

E. I. Treiger and V. P. Prikhodko, Improvement in the Quality and Operational Life of Sheet Mill Rolls [in Russian], Metallurgiya, Moscow (1989).

A. S. Trekalo and I. A. Borisov, “Improvement in manufacturing technology and heat treatment of large objects,” in: Technology, Organization and Mechanization of metal Heat Treatment and Chemical Heat Treatment [in Russian], NIIinformtyazhmash, Moscow (1977).

E. T. Dolbenko, A. I. Surovtsev, and A. I. Borisov, “Future development of technology and equipment for heat treatment of large forgings,” in: Technology, Organization of Production and Control [in Russian], NIIinformtyazhmash, Moscow (1979).

I. A. Borisov, “Effect of carbon, chromium and nickel on carbide transformation in Cr–Ni–Mo–V-steels during tempering,” Metalloved. Term. Obrab. Met., No. 9, 30–33 (1990).

I. A. Borisov, “Effect of vanadium and other carbide-forming elements on rotor steel properties,” Metalloved. Term. Obrab. Met., No. 10, 33–35 (1994).

I. A. Borisov, “Some assumptions of steel alloying theory for turbine rotor and generator steels,” Metalloved. Term. Obrab. Met., No. 3, 22–25 (2001).

I. ABorisov, “Effect of overheating on the mechanical properties of roll and forging steels, Metalloved. Term. Obrab. Met., No. 8, 20–26 (2001).

Author information

Authors and Affiliations

Additional information

Translated from Metallovedenie i Termicheskaya Obrabotka Metallov, No. 6, pp. 8–14, June, 2009.

Rights and permissions

About this article

Cite this article

Borisov, I.A., L’vova, S.S. Choice of steel for rolling mill rolls. Met Sci Heat Treat 51, 272 (2009). https://doi.org/10.1007/s11041-009-9145-5

Published:

DOI: https://doi.org/10.1007/s11041-009-9145-5