Abstract

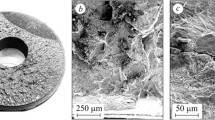

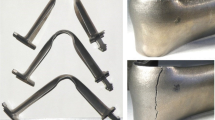

The process of final heat treatment of nuclear-power-plant steam turbine parts produced from steel 26KhN3M2FAA is developed. The quality of the metal of a commercially produced disk is studied. Conditions for obtaining a high set of mechanical properties in steel 26KhN3M2FAA combined with a reduced temperature of the ductile-brittle transition (semibrittleness temperature) are determined.

Similar content being viewed by others

References

I. A. Borisov, “Heat treatment of critical parts in power machine building,” Metalloved. Term. Obrab. Met., No. 9, 2–6 (1979).

I. A. Borisov and A. I. Borisov, “Simulation of main parameters of heat treatment of large forgings,” Metalloved. Term. Obrab. Met., No. 8, 16–18 (1995).

E. I. Kvashnina, I. A. Borisov, and E. K. Smirnova, “Effect of the cooling rate after austenization on structure formation in tempering of Cr-Ni-Mo-V steel,” in: Effect of Heat Treatment Parameters on the Structure and Properties of the Metal of Rotor Forgings [in Russian], No. 13-74-3, NIIINFORMTYaZhMASh, Moscow (1974), pp. 8–12.

A. A. Chizhik and A. A. Lanin, “Development of criterion for evaluating the crack resistance of steels during quenching,” in: Deformation and Fracture of Heat-Resistant Steels, Mater. Conf. [in Russian], MDNTP, Moscow (1983), pp. 44–46.

V. E. Loshkarev and V. V. Kubachev, “A study of intense quenching modes for complex-configuration parts,” Promysh. Teplotekh., 4(5), 73–80 (1982).

V. E. Loshkarev, “Control of quenching stresses in void cylindrical parts,” Izv. Vuzov, Chern. Metallurg., No. 11, 90–94 (1984).

A. V. Amel’yanchik, I. A. Borisov, and V. T. Politkina, “Design of expedient quenching modes for steam turbine rotor tails,” Trudy TSNIITMASh, No. 210, 25–26 (1987).

V. E. Loshkarev and G. G. Nemzer, “A study of intense quenching modes for complex-configuration parts,” Promysh. Teplotekh., 4(5), 73–80 (1982).

I. A. Borisov, “Effect of the duration of high-temperature tempering on removal of superheating texture in rotor steels,” Metalloved. Term. Obrab. Met., No. 5, 11–14 (1991).

I. R. Kryanin, I. A. Borisov, A. A. Astaf’ev, et al., A Steel, RF Inventor’s Sertif. No. 963309 [in Russian].

I. A. Borisov, “Some provisions of the theory of alloying of steels for turbine rotors and generators,” Metalloved. Term. Obrab. Met., No. 3, 22–26 (2001).

Author information

Authors and Affiliations

Additional information

__________

Translated from Metallovedenie i Termicheskaya Obrabotka Metallov, No. 6, pp. 28–33, June, 2007.

Rights and permissions

About this article

Cite this article

Borisov, I.A. Heat treatment of NPP steam turbine parts from steel 26KhN3M2FAA. Met Sci Heat Treat 49, 304–308 (2007). https://doi.org/10.1007/s11041-007-0055-0

Issue Date:

DOI: https://doi.org/10.1007/s11041-007-0055-0