Abstract

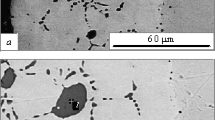

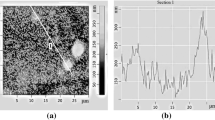

Processes of thermochemical treatment of tools, accessories, and parts from alloy steels, which make it possible to form wear-resistant carbide diffusion layers by high-temperature carburizing in a solid carburizer based on charcoal mixtures and activating nitrogen-bearing additives in the form of carbamide and versene, are described.

Similar content being viewed by others

References

G. V. Borisenok, V. A. Vasil’ev, L. G. Voroshin, et al., Thermochemical Treatment of Metals and Alloys [in Russian], Metallurgiya, Moscow (1981).

A. N. Minkevich, Thermochemical Treatment of Steel [in Russian], Mashinostroenie, Moscow (1968).

A. N. Tarasov and T. P. Kolina, “Structure and properties of carbonitrided steels 4Kh5NFS and 20Kh13 used for the production of cutting tools,” Metalloved. Term. Obrab. Met., No. 5, 32–36 (2003).

T. Babul, T. G. Kucharieva, and A. Nakonechnyi, “Effect of initial structure of tool steels on the thickness and hardness of layers obtained as a result of carbonitriding,” Metalloved. Term. Obrab. Met., No. 7, 17–30 (2004).

A. N. Tarasov, T. P. Kolina, and E. N. Evsina, “Special features of structure formation and corrosive properties of nitrogen-carbon-charged high-chromium steels,” Zashch. Met., 40, No. 1, 100–105 (2004).

V. I. Movchan, L. A. Voronina, and L. G. Pedan, “Structure of low-carbon high-speed steels after carburizing,” Metalloved. Term. Obrab. Met., No. 1, 36–38 (1987).

V. M. Pereverzev, Carbidization of High-Chromium Steels [in Russian], Izd. VGU, Voronezh (1977)

A. N. Tarasov, et al., “A method of hardening of cutting and forming tools from heat-resistant chromium steels, RF Patent No. 2205892, MPK C23C 8/76,” Byull. Izobr. Polez. Modeli, No. 16 (2003).

A. N. Tarasov, et al., “A method of nicotriding of steel parts and tools, RF Patent No.2237774, MPK C23C 8/76,” Byull. Izobr. Polez. Modeli, No. 28 (2004).

A. N. Tarasov, et al., “A method for thermochemical treatment of parts of electromagnetic valves from magnetically soft steel, RF Patent No. 2253692, MPK C23C 8/76,” Byull. Izobr. Polez. Modeli, No. 16 (2005).

K. V. Zhigunov, P. I. Malenko, and E. Yu. Ovchinnikov, “Effect of the state of the surface layer of materials on processes of thermochemical treatment,” Mashinostroitel’, No. 2, 40–42 (2004).

Author information

Authors and Affiliations

Additional information

__________

Translated from Metallovedenie i Termicheskaya Obrabotka Metallov, No. 2, pp. 32–35, February, 2007.

Rights and permissions

About this article

Cite this article

Tarasov, A.N. Structure and properties of diffusion layers formed on alloy steels due to carburizing in activated charcoal mixtures. Met Sci Heat Treat 49, 78–81 (2007). https://doi.org/10.1007/s11041-007-0015-8

Issue Date:

DOI: https://doi.org/10.1007/s11041-007-0015-8