Abstract

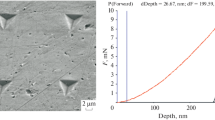

The chemical composition of phases and the structure of commercial α + β brasses are studied. The effect of heat treatment modes on the amount and morphology of α-and β′-grains and the effect of the content of iron on the composition and quantitative characteristics of silicides are determined. Practical recommendations on the choice of treatment mode and correction of chemical composition for obtaining optimum process and operating properties are suggested.

Similar content being viewed by others

References

M. V. Mal’tsev, Metallography of Commercial Nonferrous Metals and Alloys (with an Atlas of Macro-and Microstructures) [in Russian], Metallurgiya, Moscow (1979).

A. A. Presnyakov, V. V. Chervyakova, U. K. Duisemaliev, and A. V. Novikov, Brasses: Solid-State Transformations and Process Properties [in Russian], Metallurgiya, Moscow (1969).

N. Ya. Titarev, L. I. Mitina, and É. N. Mironenko, “Effect of manganese and silicon on the properties and structure of wearresistant brasses,” Izv. Vuzov, Tsvetn. Met., No. 2, 105–110 (1982).

V. V. Kozlov, A. A. Tishkov, and V. N. Fedotov, “Effect of silicon and Mn5Si3 intermetallics on the structure and mechanical properties of silicon-manganese brasses,” in: Theoretical Works on Optimization of Properties and Rational Use of Brasses and Aluminum Bronzes [in Russian], Metallurgiya, Moscow (1968).

M. D. Kopyl, A. V. Tropotov, and I. V. Kotlyarov, “Improvement of brass alloys for synchronizer rings,” Avtomob. Prom., No. 10, 26–29 (1999).

K. S. Chernyavskii, Stereology in Metal Science [in Russian], Metallurgiya, Moscow (1977).

N. B. Pugacheva, A. V. Tropotov, S. V. Smirnov, and O. S. Kuz’min, “Effect of iron content in alloyed brass LMtsAZhKS on the composition and morphology of (Fe, Mn)5Si3 silicides,” Fiz. Met. Metalloved., 89(1), 62–69 (2000).

S. V. Smirnov, N. B. Pugacheva, A. N. Soloshenko, and A. V. Tropotov, “A study of plastic deformation of complexly alloyed brass,” Fiz. Met. Materialoved., 93(6), 96–100 (2002).

S. V. Smirnov, N. B. Pugacheva, M. V. Myasnikova, et al., “Micromechanics of fracture and deformation of brass,” Fiz. Mesomekh., No. 7, Part 1, 165–168 (2004).

I. I. Kurbatkin, I. F. Pruzhinin, V. I. Falkon, et al., “Effect of chemical composition and treatment modes on mechanical and operating properties of silicon-manganese brasses,” Tsvetn. Met., No. 9, 60–63 (1996).

Author information

Authors and Affiliations

Additional information

__________

Translated from Metallovedenie i Termicheskaya Obrabotka Metallov, No. 2, pp. 23–29, February, 2007.

Rights and permissions

About this article

Cite this article

Pugacheva, N.B. Structure of commercial α + β brasses. Met Sci Heat Treat 49, 67–74 (2007). https://doi.org/10.1007/s11041-007-0013-x

Issue Date:

DOI: https://doi.org/10.1007/s11041-007-0013-x