Abstract

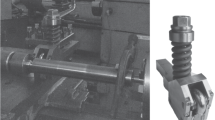

Experience in the thermomechanical treatment of long stepped preforms for shafts (including torsion ones), studs, forcing bolts, and other articles from high-strength and maraging steels with the use of cold lengthwise rolling in dead rolls is described. The used variants of TMT make it possible to obtain hardened highly loaded machine parts with high quality and performance parameters.

Similar content being viewed by others

References

M. L. Bernshtein, Thermomechanical Treatment of Metals and Alloys [in Russian], Vols. 1 and 2, Metallurgiya, Moscow (1968).

M. L. Bernshtein, V. A. Zaimovskii, and L. M. Kaputkina, Thermomechanical Treatment of Steel [in Russian], Metallurgiya, Moscow (1983).

O. I. Shavrin, Technology and Equipment for Thermomechanical Treatment of Machine Parts [in Russian], Mashinostroenie, Moscow (1983).

A. K. Grigor’ev and G. E. Kodjaspirov, Thermomechanical Hardening of Steel in Blanking Production [in Russian], Mashinostroenie, Moscow (1985).

G. E. Kodjaspirov and I. Kim, Advanced Straightening Methods of Metallic Materials, St. Petersburg Technical University, St. Petersburg (2000).

G. E. Kodjaspirov, A. I. Rudskii, and V. V. Rybin, Physical Foundations and Resource-Saving Processes for Fabricating Articles by Plastic Deformation [in Russian], Nauka, St. Petersburg (2006).

G. G. Semibratov, Precision Rolling of Shafts and Axles [in Russian], Mashinostroenie, Leningrad (1980).

G. A. Agas’yants, A. M. Legkodukh, and N. S. Kudryavtseva, “Effect of initial structure on the properties of steel 45KhN2MFA-Sh after cold rolling,” Stal’, No. 11, 75–76 (2002).

G. A. Agas’yants, “Effect of accumulation of strain in cold rolling on the deformability of steels,” Kuzn.-Shtamp. Proizv., No. 8, 9–13 (2002).

G. A. Agas’yants, G. G. Semibratov, G. E. Kodjaspirov, et al., “PTMT of steel 45KhN2MFA-Sh with the use of cold lengthwise rolling in dead rolls,” Metalloved. Term. Obrab. Met., No. 8, 24–27 (2002).

V. S. Sysoeva, N. S. Maslova, G. A. Chumak, and E. D. Tsypkina, Heavy-Duty Crawler Torsion Shafts [in Russian], TsNIIinformatsii, Moscow (1980).

G. A. Agas’yants, “A study of conditions of the effect of hardening rolling on the properties of pins from steel 30KhGSN2A,” Stal’, No. 7, 44–47 (2002).

G. A. Agas’yants, “Deformation and hardening of maraging steel N18K9M5T by cold rolling in dead rolls,” Kuzn.-Shtamp. Proizv., No. 10, 13–16 (2001).

Author information

Authors and Affiliations

Additional information

__________

Translated from Metallovedenie i Termicheskaya Obrabotka Metallov, No. 1, pp. 34–37, January, 2007.

Rights and permissions

About this article

Cite this article

Agas’yants, G.A., Semibratov, G.G. & Kodjaspirov, G.E. Experience in TMT with the use of cold lengthwise rolling in dead rolls. Met Sci Heat Treat 49, 29–31 (2007). https://doi.org/10.1007/s11041-007-0005-x

Issue Date:

DOI: https://doi.org/10.1007/s11041-007-0005-x