Abstract

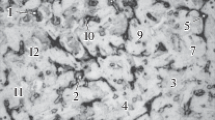

The main advantages of boron-bearing steels used for production of rolled sections at cold upset shops of Russian automotive plants are considered. A thermodynamic model for the majority of boron-bearing steels for high-strength fasteners is used to plot nomograms characterizing the effect of titanium, aluminum, nitrogen, and boron on the amount of nitrides and oxides segregated in crystallization and on the content of effective boron. The effect of effective boron on the characteristics of hardenability is estimated. The studies conducted are used for determining the range of permissible contents of titanium and aluminum ensuring through hardenability of rolled bars from steels 12G1R, 20G2R, and 30G1R up to 25 mm in diameter.

Similar content being viewed by others

REFERENCES

M. V. Bobylev, “Prospects of the use of boron-bearing steels for fabricating progressive kinds of high-strength automotive fasteners,” Nats. Metallurg., No. 4, 68–73 (2003).

M. V. Bobylev, “Information technologies for controlling the quality of boron-bearing steels for automobile makers,” in: L. V. Kozhitov (ed.), Scientific and Engineering Support of the Activity of Enterprises, Institutes, and Companies [in Russian], Izd. MGIU, Moscow (2003), pp. 355–369.

M. V. Bobylev, “Control of the quality of boron-bearing steels for the production of high-strength fasteners,” Metalloved. Term. Obrab. Met., No. 11, 34 (2001).

M. V. Bobylev, A. A. Ugarov, E. I. Gontaruk, and A. A. Lekhtman, “Advanced kinds of rolled sections for purposes of the automotive industry,” in: Rep. Int. Seminar “Modern Achievements in Metallurgy and Steel Production Processes for the Automotive Industry” [in Russian], Metallurgizdat, Moscow (2004), pp. 255–264.

M. V. Bobylev, V. T. Borisov, V. A. Petrovskii, et al., “Quality control for boron bearing steels based on modeling of nitride formation during crystallization,” in: Proc. 41st Mechanical Working and Steel Processing, Baltimore, MD, USA, Oct. 24–27 (1999), pp. 851–860.

E. M. Grinberg, The Physical Metallurgy of Boron-Bearing Structural Steels [in Russian], MISiS, Moscow (1997).

V. T. Borisov, The Theory of Crystallization of the Double-Phase Zone [in Russian], Metallurgiya, Moscow (1989).

Author information

Authors and Affiliations

Additional information

__________

Translated from Metallovedenie i Termicheskaya Obrabotka Metallov, No. 5, pp. 51 – 55, May, 2005.

Rights and permissions

About this article

Cite this article

Bobylev, M.V., Koroleva, E.G. & Shtannikov, P.A. Promising Sparingly Alloyed Boron-Bearing Steels for the Production of High-Strength Fasteners. Met Sci Heat Treat 47, 210–214 (2005). https://doi.org/10.1007/s11041-005-0053-z

Issue Date:

DOI: https://doi.org/10.1007/s11041-005-0053-z