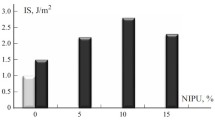

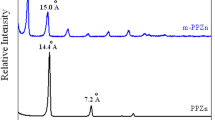

The outstanding improvement in the physical properties of cyanate esters (CEs) compared with those of competitor resins, such as epoxies, has attracted appreciable attention recently. Cyanate esters undergo thermal polycyclotrimerization to give polycyanurates (PCNs). However, like most thermo setting resins, the main draw back of CEs is brittleness. To over come this disadvan tage, CEs can be toughened by the introduction of polytetramethylene glycol (PTMG), a hydroxyl-terminated polyether. How ever, PTMG has a detrimental impact on Young’s modulus. To simultaneously enhance both the ductility and the stiffness of CE, we added PTMG and an organoclay (mont morillonite, MMT) to it. A series of PCN/PTMG/MMT nanocomposites with a constant PTMG weight ratio was pre pared, and the resulting nanophase morphology, i.e., the degree of filler dispersion and distribution in the composite and the thermomechanical properties, in terms of glass-transition behaviour, Young’s modulus, tensile strength, and elongation at break, were examined using the scanning elec tron micros copy (SEM), a dynamic mechanical analysis (DMA), and stress–strain measurements, re spectively. It was found that, at a content of MMT below 2 wt.%, MMT nanoparticles were distributed uniformly in the matrix, suggesting a lower degree of agglomeration for these materials. In the glassy state, the significant increase in the storage modulus revealed a great stiffening effect of MMT due to its high Young’s modulus. The modification with PTMG led to a 233% greater elongation at break compared with that of neat PCN. The nanocomposites exhibited an invariably higher Young’s modulus than PCN/PTMG for all the volume factors of organoclay examined, with the 2 wt.% material displaying the most pronounced in crease in the modulus, in agreement with micros copy results.

Similar content being viewed by others

References

S. Sinha Ray and M. Okamoto, “Polymer/layered silicate nanocomposites: a review from preparation to processing,” Progr. Polym. Sci., 28, 1539–1641 (2003).

D. P. R. Kint, G. Seeley, M. Gio-Batta, and A. N. Burgess, “Structure and properties of epoxy-based layered silicate nanocomposites,” J. Macromol. Sci., Pt. B, Phys., 44, 1021–1040 (2005).

C. D. Rudd and R. W. Shaw, “Nanostructures in polymer matrices,” in: A Report on Work shop Organized by the University of Nottingham and Sponsored by U.S. Army European Research Office, London (2001), pp. 1–38.

C. P. Reghunadhan Nair, D. Mathew, and K. Ninan, “Cyanateester resins, recent developments,” Adv. Polym. Sci., 155, 1–99 (2001).

K. Liang, G. Li, H. Toghiani, J. H. Koo, and C. U. Pittman Jr, “Cyanate ester/polyhedral oligomeric silsesquioxane (POSS) nanocomposites: synthesis and characterization,” Chem. Mater., 18, 301–312 (2006).

S. Ganguli, D. Dean, K. Jordan, G. Price, and R. Vaia, “Mechanical properties of intercalated cyanate ester-layered silicate nanocomposites,” Polymer, 44, 1315–1319 (2003).

I. Hamerton, “Introduction to cyanate ester resins,” in: I. Hamerton (ed.), Chemistry and Technology of Cyanate Ester Resins, Blackie, Glasgow (1994), pp. 1-6.

A. Fainleib, J. Grenet, M. R. Garda, J. M. Saiter, O. Grigoryeva, O. V. Grytsenko, N. Popescu, and M. C. Enescu, “Poly(bisphenol A)cyanurate network modified with poly(butyleneglycol adipate). Thermal and mechanical properties,” Polym. Degrad. Stab., 81, 423–430 (2003).

J. N. Suman, J. Kathi, and S. Tammishetti, “Thermoplastic modifica tion of monomeric and partially polymerized Bisphenol A dicyanate ester,” Eur. Polym. J., 41, 2963–2972 (2005).

A. M. Fainleib, O. P. Grigoryeva, and P. Pissis, “Modification of polycyanurates by polyethers, polyesters and polyurethanes. Hybrid and interpenetrat ing polymer networks,” in: E. B. Burlakova, A. E. Shilov, S. D. Varfolomeev, and G. E. Zaikov (eds.), Chemical and Biological Kinetics. New Horizons. Vol. 1. Chemical Kinetics, VSP In t. Publ., Leiden–Boston (2005), pp. 405–437.

A. M. Fainleib, O. P. Grigoryeva, and P. Pissis, “Recent advances in reactive modifica tion of polycyanurate net works,” in: G. E. Zaikov (ed.), Handbook of Polymer Research. Vol. 20, Ch. 7, Nova Sci. Publ., New York (2006).

A. M. Fainleib, O. P. Grigoryeva, and D. Hourston, “Synthe sis of inhomogeneous modified polycyanurates by reactive blending of bisphenol A dicyanate ester and polyoxypropyleneglycol,” Macromol. Symp., 164, 429–442 (2001).

A. M. Fainleib, D. J. Hourston, O. P. Grigorieva, T. A. Shantalii, and L. M. Sergeeva, “Structure development in aromatic polycyanurate net works modified with hydroxyl-terminated polyethers,” Polymer, 42, 8361–8372 (2001).

A. M. Fainleib, O. P. Grigorieva, and D. J. Hourston, “Structure–properties relationships for bisphenol A polycyanurate network modified with polyoxytetramethylene glycol,” Int. J. Polym. Mater., 51, 57–75 (2002).

S. Kripotou , P. Pissis, E. Kontou, A. M. Fainleib, O. Grygoryeva, and I. Bey, “Structure–property relation ships in brittle polymer networks modified by flexible cross-links,” Mater. Sci., 24, No. 2/2, 477–492 (2006).

S. Kripotou, P. Pissis, E. Kontou, A. M. Fainleib, O. Grigoryeva, and I. Bey, “Polycyanurate networks modified by polyoxytetramethylene glycol,” Polym. Bull., 58, 93–104 (2007).

S. Ray, and A. J. Easteal, “Advances in polymer–filler composites: macro to nano,” Mater. Manufact. Proc., 22, 741–749 (2007).

M. Biswas and S. Sinha Ray, “Recent progress in synthesis and evaluation of polymer–montmoril lonite nanocomposites,” Adv. Polym. Sci., 155, 167–221 (2001).

M. Alexandre and P. Dubois, “Polymer-layered silicate nanocomposites: preparation, properties and uses of a new class of materials,” Mater. Sci. Eng., 28, 1-63 (2000).

E. P. Giannelis, R. Krishnamoorti, and E. Manias, “Polymer–silicate nanocomposites: model systems for confined polymers and polymer brushes,” Adv. Polym. Sci., 138, 107–147 (1999).

Q. H. Zeng, A. B. Yu, G. Q. (Max) Lu, and D. R. Paul, “Clay-based polymer nanocomposites: research and commercial development,” J. Nanosci. Nanotechnol., 5, 1574–1592 (2005).

S. C. Tjong, “Structural and mechanical properties of polymer nanocomposites,” Mater. Sci. Eng., R 53, 73–197 (2006).

Y. Feng, Z. Fang, W. Mao, and A. Gu, “Study on the structure and properties of cyanate ester/bentonite nanocomposites,” J. Appl. Polym. Sci., 96, 632–637 (2005).

T. J. Wooster, S. Abrol, and D. R. MacFarlane, “Rheological and mechancal properties of percolated cyanate ester nanocomposites,” Polymer, 46, 8011–8017 (2005).

G. I. Anthoulis, E. Kontou, A. Fainleib, I. Bei, and Y. Gomza, “Synthe sis and characterization of polycyanurate montmorillo nite nanocomposites,” J. Polym. Sci., Pt. B, Polym. Phys. (in press).

Z. Fang, H. Shi, A. Gu, and Y. Feng, “Effect of bentonite on the structure and mechanical properties of CE/CTBN system,” J. Mater. Sci., 42, 4603–4608 (2007).

K. Matsunaga, M. Tajima, and Y. Yoshida, “Thermal degradation of carboxylate-based polyurethane anionomers,” J. Appl. Polym. Sci., 101, 573–579 (2006).

E. Kontou and P. Farasoglou, “Determination of the true stress–strain behaviour of polypropylene,” J. Mater. Sci., 33, 147–153 (1998).

E. Kontou and M. Niaounakis, “Thermo-mechanical properties of LLDPE/SiO2 nanocomposites,” Polymer, 47, 1267–1280 (2006).

E. Kontou and G. Anthoulis, “The effect of silica nanoparticles on the thermomechanical properties of polystyrene,” J. Appl. Polym. Sci., 105, 1723–1731 (2007).

D. Ratna, N. R. Manoj, R. Varley, R. K. Singh Raman, and G. P. Simon, “Clay-reinforced epoxy nanocomposites,” Polym. Int., 52, 1403–1407 (2003).

A. Bartolotta, G. Di Marco, G. Carini, G. D’Angelo, G. Tripodo, A. Fainleib, and V. P. Privalko, “Relaxation in semi-interpenetrating polymers network of linear polyurethane and heterocyclic polymer networks,” J. Non-Cryst. Solids, 235–237, 600–604 (1998).

O. Becker, R. Varley, and G. Simon, “Morphology, thermal relaxations and mechanical properties of layered silicate nanocomposites based upon high-functionality epoxy resins,” Polymer, 43, 4365–4373 (2002).

I. Mondragón, L. Solar, A. Nohales, C. I. Vallo, and C. M. Gómez, “Properties and structure of cyanate ester/polysulfone/organoclay nanocomposites,” Polymer, 47, 3401–3409 (2006).

M. Bauer and J. Bauer, “As pects on the ki net ics, mod el ling and sim u la tion of net work build-up during cyanate ester cure,” in: I. Hamerton (ed.), Chemistry and Technology of Cyanate Ester Resins, Blackie, Glasgow (1994), pp. 58–85.

T. J. Wooster, S. Abrol, and D. R. MacFarlane, “Cyanate ester polymerization catalysis by layered silicates,” Polymer, 45, 7845–7852 (2004).

X. Kornmann, R. Thomann, R. Mülhaupt, J. Finter, and L. A. Berglund, “High performance epoxy-layered silicate nanocomposites,” Polym. Eng. Sci., 42, 1815–1826 (2002).

C. Basara, U. Yilmazer, and G. Bayram, “Synthesis and characterization of epoxy based nanocomposites,” J. Appl. Polym. Sci., 98, 1081–1086 (2005).

Author information

Authors and Affiliations

Additional information

Russian translation published in Mekhanika Kompozitnykh Materialov, Vol. 45, No. 2, pp. 255–268, March–April, 2009.

Rights and permissions

About this article

Cite this article

Anthoulis, G.I., Kontou, E., Fainleib, A. et al. Polytetramethylene glycol-modified polycyanurate matrices reinforced with nanoclays: synthesis and thermomechanical performance. Mech Compos Mater 45, 175–182 (2009). https://doi.org/10.1007/s11029-009-9073-x

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11029-009-9073-x