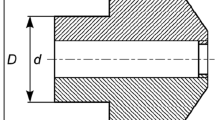

We consider various methods of monitoring technological processes in modern machine-building production, including statistical methods of product quality management. The problem of constructing measurement control procedures for two parameters in those cases where the deviation of the quality index from the nominal value is described by a generalization of the Rayleigh distribution with two parameters is posed and solved. The distributions of control statistics are investigated. Numerical procedures are described that make it possible to calculate the distribution functions of statistics with sufficient accuracy for practical purposes. The operational characteristics of a control plan using statistics that estimate two distribution parameters and a plan for a one-parameter distribution model are compared. It is shown that close values of consumer and producer risks in comparable situations with two-parameter control are provided with a slight increase in the sample size compared to the one-parameter case. The results obtained will be useful in the organization of acceptance control procedures for parts with external and internal cylindrical surfaces.

Similar content being viewed by others

Notes

GOST R ISO 7870-2-2015. Statistical methods. Control cards. Part 2. Shewhart's Control Charts.

References

S. N.Grigoriev, D. A. Masterenko, V. I. Teleshevskii, and P. N. Emelyanov, Meas. Tech., 55, No. 11, 1311–1315 (2013), https://doi.org/https://doi.org/10.1007/s11018-013-0126-0.

S. N. Grigoriev and V. I. Teleshevskii, Meas. Tech., 54, No. 7, 744–749 (2011), https://doi.org/https://doi.org/10.1007/s11018-011-9798-5.

V. I. Teleshevskii, Measuring informatics in mechanical engineering, Vestn. MSTU "STANKIN," No. 1, 33–38 (2008).

S. N. Grigoriev, M. S. Migranov, S. R. Shekhtman, A. M. Migranov, A. A. Ershov, and P. M. Pivkin, Proc. SPIE 11914, SPIE Future Sensing Technologies 2021, 14 November 2021, 119141C, https://doi.org/10.1117/12.2605753.

S. N. Grigoriev, V. A. Sinopalnikov, M. V. Tereshin, and V. D. Gurin, Meas. Tech., 55, No. 5, 555–558 (2012), https://doi.org/https://doi.org/10.1007/s11018-012-9999-6.

V. I. Leun, E. V. Nikolaeva, and A. V. Tignibidin, The trend in the development of theory and practice of creating control de vices to improve the accuracy and productivity of grinding operations of parts and tools in technological processes of mechanical engineering, instrumentation and tool production, Dyn. Syst. Mech. Mach., No. 2, 251–254 (2012).

S. N. Grigoriev and G. M. Martinov, Proc. CIRP, No. 14, 517–522 (2014), https://doi.org/10.1016/j.procir.2014.03.051.

S. N. Grigoriev and G. M. Martinov, Proc. CIRP, No. 41, 858–863 (2016), https://doi.org/10.1016/j.procir.2015.08.031.

D. J. Wheeler and D. S. Chambers, Understanding Statistical Process Control, Addison-Wesley (1990), 310 p.

Yu. P. Adler and V. L. Shper, Prakticheskoe rukovodstvo po statisticheskomu upravleniyu processami (Practical Guide to Statistical Process Management), Alpina Publisher, Moscow (2019), 320 p.

V. A. Lapidus, Sistema Shuharta (Shewhart’s System), Priority Publ., N. Novgorod (2004), 65 p.

W. E. Deming, Overcoming the Crisis: A New Paradigm of Managing People, Systems and Processes, MIT Center for Advanced Engineering Study, Cambridge, MA (1982).

M. I. Rozno, Statisticheskij kontrol’ kachestva produkcii po al’ternativnomu priznaku pri izmenyonnom dopuske (method AKUD) [Statistical quality control of products on an alternative basis with a modified tolerance (AKUD method)], Reliab. Qual. Control, No. 2, 44–52 (1992).

S. H. Steiner, P. L. Geyer, and G. O. Wesolowsky, International Journal of Production Research, No. 1, 75–91 (1994), https://doi.org/https://doi.org/10.1080/00207549408956917.

S. H. Steiner, P. L. Geyer, and G. O. Wesolowsky, Quality and Reliability Engineering International, 12, No. 5, 345–353 (1996), https://doi.org/https://doi.org/10.1002/(SICI)1099-1638(199609)12:5<345::AID QRE11>3.0.CO;2-M.

M. I. Rozno, Regulation of processes based on data on an alternative feature by a narrowed tolerance, Methods Qual. Manage., No. 12, 27–33 (2001).

V. G. Grigorovich, N. O. Kozlova, and S. V. Yudin, Method of estimating the size grouping center in production conditions at ARL, Avtomatizaciya tekhnologicheskih processov v mashinostroenii (Automation of Technological Processes in Mechanical Engineering), Volgograd State Technical University, Volgograd (1995), pp. 197–202.

V. G. Grigorovich, N. O. Kozlova, and S. V. Yudin, Informacion no-statisticheskie metody regulirovaniya tekhnologicheskih pro cessov [Information and statistical methods of regulation of tech nological processes], Forging Stamping Prod., No. 9, 27–29 (2000).

D. A. Masterenko and A. S. Metel, Mech. Ind., 18, No. 7, 702 (2017), https://doi.org/https://doi.org/10.1051/meca/2017054.

D. A. Masterenko, Comparison of methods for regulation processes based on measuring control information on an alternative basis by the narrowed tolerance, Vestn. MSTU "STANKIN," No. 3(42), 74–79 (2017).

S. N. Grigoriev, P. N. Emelyanov, D. A. Masterenko, and S. E. Ped’, Sampling by variables for Rayleigh distributed lots, Izmerit. Tekh., No. 6, 28–35 (2022), https://doi.org/10.32446/0368-1025it.2022-6-28-35.

Yu. A. Rozanov, Teoriya veroyatnostej, sluchajnye pro cessy i matematicheskaya statistika (Probability Theory, Random Processes and Mathematical Statistics), Nauka Publ., Moscow (1985), 320 p.

A. L. Orlov, Prikladnaya statistika (Applied Statistics), Examen Publ., Moscow (2004), 483 p.

S. M. Raza, M. M. Butt, and A. F. Siddiqi, Shewhart control charts for Rayleigh distribution in the presence of Type I censored data, J. ISOSS, 2, No. 2, 210–217 (2016).

M. V. Kozlov and A. V. Prohorov, Vvedenie v matematicheskujy statistiku (Introduction to Mathematical Statistics), MGU Publ., Moscow (1987), 264 p.

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Izmeritel’naya Tekhnika,No. 9, pp. 24–32, September, 2022.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Grigoriev, S.N., Emelyanov, P.N., Masterenko, D.A. et al. Construction of Two-Parameter Procedures for Measuring Control of Batches of Parts with Size Distribution According to the Rayleigh Law. Meas Tech 65, 642–651 (2022). https://doi.org/10.1007/s11018-023-02134-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11018-023-02134-8