A design is presented for a hardware–software package based on a light-section device and intended for carrying out automated measurements of surface roughness. Package design solutions are presented and the metrological characteristics and features of the software are examined.

Similar content being viewed by others

References

P. N. Emelyanov and N. Yu. Cherkasova, “An investigation of drilling accuracy,” Vest. MGTU Stankin, No. 4, 31–33 (2012).

S. N. Grigor’ev, V. I. Teleshevskii, A. V. Glubokov, et al., “Challenges in providing metrological support for machine engineering preproduction,” Izmer. Tekhn., No. 5, 27–29 (2012).

S. N. Grigor’ev, D. A. Masterenko, V. I. Teleshevskii, and P. N. Emelyanov, “The state of the art and prospects for developing metrological support for machinery production,” Izmer. Tekhn., No. 11, 56–59 (2012).

S. N. Grigor’ev and V. I. Teleshevskii, “Measurement challenges in forming processes,” Izmer. Tekhn., No. 7, 3–7 (2011).

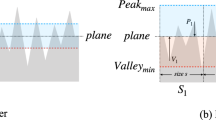

GOST 2789–73, Surface Roughness. Parameters and Characteristics.

S. N. Grigor’ev, A. A. Kutin, and V. A. Dolgov, “Principles for development of digital manufacturing in machine engineering,” Vest. MGTU Stankin, No. 4, 10–15 (2014).

V. A. Klevalin, A. Yu. Polivanov, and K. V. Shatunov, “Improving the accuracy of machine vision in industrial robots through image sensor calibration,” Vest. MGTU Stankin, No. 1, 34–37 (2013).

V. I. Teleshevskii, A. V. Shulepov, and E. M. Rozdina, “A method of intelligent computer-aided microscopy for measuring article linear and angular dimensions,” Izmer. Tekhn., No. 8, 3–6 (2011).

I. V. Latonov and A. V. Shulepov, “A non-contact method for estimating surface roughness using a digital image of the surface created by a measurement microscope optical system,” Vest. MGTU Stankin, No. 1, 141–145 (2013).

V. I. Teleshevskii, A. V. Shulepov, and E. M. Rozdina, “Methods for improving the accuracy of universal and toolroom computer-aided measurement microscopes,” Tekhnol. Mashinostr., No. 1, 41–44 (2012).

V. I. Teleshevskii and A. V. Bogomolov, “Computerization of contact interferometers in white light based on optical image processing,” Izmer. Tekhn., No. 7, 35–38 (2006).

A. A. Zuykov and A. V. Shulepov, “Improving measurement accuracy for small objects using special sighting systems in computerized measurement microscopes,” Pribory, No. 9, 39–44 (2012).

Microscopes, http://tut.ru/15917, accessed April 1, 2015.

S. E. Ped’, P. V. Druzhinin, and D. S. Shcherbitskii, State Reg. Cert. Comp. Progr., No. 2015610600, “Software for a computerized light-section device,” Progr. EVM, Bazy Dann., Topol. Integr. Mikroskh. (2015).

GOST 9847-79, Optical Instruments for Surface Roughness Measurement. Types and Principal Parameters.

This work was undertaken with the support of the RF Ministry of Education and Science (State Assignment No. 9.2545. 2014/K, Agreement No. 14.593.21.0004 of December 4, 2014, Unique Project Identifier FMEFI59314X0004).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Izmeritel’naya Tekhnika, No. 7, pp. 18–21, July, 2015.

Rights and permissions

About this article

Cite this article

Ped’, S.E., Druzhinin, P.V. Automation of Surface Roughness Measurements. Meas Tech 58, 752–756 (2015). https://doi.org/10.1007/s11018-015-0788-x

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11018-015-0788-x