The principle underlying the procedure used to monitor the vibrations that arise in the course of machining of thin-walled workpieces by milling cutters with cutting part made of a hard alloy and cubic boron nitride by means of a real-time measurement information system is considered. A comparison of the level of vibrations with the geometric parameters and roughness of segments of the machined surface is carried out.

Similar content being viewed by others

References

P. N. Emel’yanov et al., “Contemporary state and outlook for development of metrological assurance in the machine-building industry,” Izmer. Tekhn., No. 11, 56–59 (2012); Measur. Techn., 55, No. 11, 1311–1315 (2012).

V. V. Yurkevich, “Measurement of cutting tool vibrations during turning,” Izmer. Tekhn., No. 7, 22– 24 (2006); Measur. Techn., 49, No. 7, 660–663 (2006).

A. V. Glubokov, S. V. Glubokova, and V. I. Teleshevsky, “The automated choice of methods and instruments for measuring deviations of arrangement,” Izmer. Tekhn., No. 6, 30–33 (2012); Measur. Techn., 55, No. 6, 637–642 (2012).

S. N. Grigoriev et al., “Control of parameters of the cutting process on the basis of diagnostics of the machine tool and workpiece,” Izmer. Tekhn., No. 5, 46–48 (2012); Measur. Techn., 55, No. 5, 555–558 (2012).

S. N. Grigoriev and V. I. Teleshevskii, “Measurement problems in technological shaping processes,” Izmer. Tekhn., No. 7, 3–7 (2011); Measur. Techn., 54, No. 7, 744–749 (2011).

M. P. Kozochkin, A. N. Porvatov, and F. S. Sabirov, “The fitting of technological equipment with measurement information systems,” Izmer. Tekhn., No. 5, 29–32 (2012); Measur. Techn., 55, No. 5, 530–534 (2012).

S. N. Grigoriev et al., “Technical diagnostics of milling machines in computer-aided production,” Kontr. Diagnost., No. 8, 48–54 (2011).

A. V. Gusev, M. P. Kozochkin, and A. N. Porvatov, “Development of mobile systems for monitoring and diagnostics of machine tool assemblies,” Sprav. Inzh. Zh., No. 3, 20–23 (2011).

V. I. Zavgorodnii et al., “Influence of dynamic characteristics of a tool and workpiece on the results of vibroacoustic monitoring of the cutting process,” STIN, No. 6, 13–17 (2010).

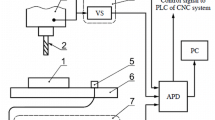

A. V. Isaev, M. P. Kozochkin, and A. N. Porvatov, “Measurement information system for monitoring vibrations in metal working,” Metrologiya, No. 8, 18–25 (2011).

V. A. Grechishnikov, D. V. Kosarev, and V. A. Kosarev, “Reducing the level of vibrations in cutting inner threads by means of thread milling cutters equipped with removeable hard-alloy plates,” STIN, No. 6, 21–24 (2010).

I. G. Zharkov, Vibrations in Machining by Means of Bit Tools [in Russian], Mashinostroenie, Leningrad (1986).

A. V. Isaev and V. A. Grechishnikov, “Use of cutting plates with rectilinear edge for machining curvilinear segments of a profile,” STIN, No. 1, 26–30 (2010).

A. I. Isakov and I. V. Chulin, “Experimental studies of the efficiency of a controlled face milling cutter with cutting elements made of STM in machining of graduated grooves,” Sprav. Inzh. Zh., No. 13, 23–25 (2012).

M. P. Kozochkin and N. V. Solis, “Study of the relationship between vibrations in cutting and the quality of the resulting surface,” Vest. RUDN. Inzh. Issled., No. 2, 16–23 (2009).

I. V. Chulin, “Influence of layout angle φ on the durability of form milling cutters,” STIN, No. 11, 16–17 (2010).

V. R. Kuptsov, “A study of methods of milling treatment applied to the production of thin-walled stationary base members,” Tekhnol. Mashinostr., No. 2 (128), 13–16 (2013).

V. A. Grechishnikov, V. A. Kosarev, and D. V. Kosarev, “Increasing the vibration stability of a sectional cutting tool,” Sprav. Inzh. Zh., No. 5, 27–30 (2009).

M. P. Kozochkin, N. A. Kochinev, and F. S. Sabirov, “Diagnostics and monitoring of complex production processes using measurement of vibration-acoustic signals,” Izmer. Tekhn., No. 7, 30–34 (2006); Measur. Techn., 49, No. 7, 672–678 (2006).

F. S. Sabirov and S. Yu. Savinov, “Diagnostics and control of the accuracy of axis drives for automatically controlled multi-coordinate metal cutting machines,” Izmer. Tekhn., No. 8, 20–22 (2011); Measur. Techn., 54, No. 8, 879–882 (2011).

V. A. Grechishnikov and A. I. Isakov, “Controlled face milling cutters with cutting elements made of STM,” Vestn. MGTU Stankin, No. 1, 12–14 (2012).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Izmeritel’naya Tekhnika, No. 10, pp. 42–46, October, 2013.

Rights and permissions

About this article

Cite this article

Isaev, A.V., Kozochkin, M.P. Use of a Measurement Information System to Increase the Precision with which Thin-Walled Parts are Machined on Numerically Controlled Milling Machines. Meas Tech 56, 1155–1161 (2014). https://doi.org/10.1007/s11018-014-0348-9

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11018-014-0348-9