Abstract

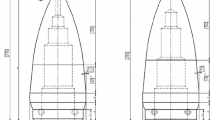

The main parameter that determines the quality of rolled products is the accuracy of geometric dimensions. The accuracy of the pipe wall thickness is characterized by the nominal value and the range of permissible values, i.e., the tolerance range. To obtain the nominal values of the pipe wall thickness in the rolling mill, the same roll profile (groove system) and a limited pool of diameters of cylindrical mandrels are used. Based on the diameter of rolling mandrels selected from the existing database and the need to obtain the nominal thickness of the pipe wall, the position of the rolls in the stands of the finishing group is determined, which determines the actual accuracy of wall thickness. The article presents an algorithm for calculating the rational diameters of cylindrical mandrels and provides some results of pilot testing of this technical solution.

Similar content being viewed by others

References

Zayats AA, Bobrikov EP, Vorotnikov VA, Novikov NN (1992) Analysis of the influence of mill roll displacement for longitudinal mandrel rolling on pipe accuracy. Tematich. Sb. Nauchn. Tr.. Development of Equipment and Technology in Pipe Production, Moscow, Metallurgiya, pp 31–34

Kagarlitsky AS, Plyatkovsky OA (1996) Improving the accuracy of pipe sizes when rolling on continuous mandrel mills. Byul NTiEI 8:43–45

Shifrin EI, Vydrin AV, Churbanov VI, Shirokov VV, Nikityuk AV, Belomestnov AK (2010) Analysis of forming and improvement of pipe accuracy during mandrel rolling. Byul NTiEI 12:49–54

Kuznetsov ED, Nixdorf BY (2008) Investigation of variations in the wall thickness of hot-rolled pipes. Stal 12:101–103

Struin DO et al (2011) On the issue of determining geometric parameters when rolling pipes in three-roll pass. Nauch Poisk Tekh Nauk 2: (Chelyabinsk SUSU Publ. House)

Chernykh IN, Shendyapin KV, Game EA (2021) Investigation of the influence of mandrel diameter on pipe quality during longitudinal rolling. Metallurg 2:90–93

Vydrin AV, Chernykh IN, Struin DO, Shkuratov EA, Khramkov EV (2014) Comparative analysis of mandrel longitudinal rolling of pipes using passes formed by a different number of rolls. Tr Mezhdunar Nauch-Prakt Konf: 143–150 (Truby-2014)

Zilberg YV (2009) Theory of Metal Treatment by Pressure: Handbook. Dnepropetrovsk, Porogi

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Metallurg, No. 11, pp 114–117, November 2023. https://doi.org/10.52351/00260827_2023_11_114

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Chernykh, I.N., Ulyanov, A.G., Trubnikov, K.V. et al. Rational use of rolling mill mandrels. Metallurgist (2024). https://doi.org/10.1007/s11015-024-01668-8

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11015-024-01668-8