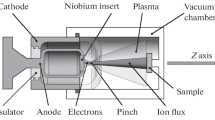

Selective laser processing of thin surface layers of metallic alloys selectively affects certain defective areas, such as stress concentrators, fracture nuclei, crack tips, and nanoscale particles. The rest of the material is practically unaffected. The method of selective laser processing increases both the microhardness and fracture toughness of, particularly, thin ribbons of hard and brittle amorphous- nanocrystalline metal alloys. It is essential that the initial amorphous-nanocrystalline structure of the material is preserved. The impact of a nanosecond laser pulse of high power density on the surface of a metal alloy is accompanied by laser-induced breakdown plasma, shock wave, and impulsive heating. The heating of the material is preceded by the passage of a compression shock wave capable of initiating local deformations and damages. The uneven heating of the material is primarily manifested in the defective areas and can lead to the relaxation of mechanical stresses due to plastic deformation. To study the interaction between the thermal front initiated by a laser pulse and defects in the surface layer of a metal alloy, it is necessary to improve the physical and mathematical models of these processes.

Similar content being viewed by others

References

R. A. Andrievskii and A. V. Ragulya, Nanostructured Materials [in Russian], Akademiya, Moscow (2005).

A. M. Glezer and N. A. Shurygina, Amorphous-Nanocrystalline Alloys [in Russian], Fizmatlit, Moscow (2013).

I. V. Ushakov and I. S. Safronov, “Directed changing properties of amorphous and nanostructured metal alloys with help of nanosecond laser impulses,” CIS Iron and Steel Review, 22, 77–81 (2021).

I. V. Ushakov and A. D. Oshorov, “Viscosity of microdestruction of multilayer composite and method of its revealing,” Mater. Sci. Forum, 1052, 110–115 (2022); https://doi.org/10.4028/p-5q4060.

N. A. Chichenev, S. M. Gorbatyuk, O. A. Kobelev, and A. N. Pashkov, “Improving the thermal fatigue strength of hot-working tools by laser treatment,” Mater. Res. Proc., 21, 43–50 (2022); https://doi.org/10.21741/9781644901755-8

M. G. Isaenkova, Yu. A. Perlovich, A. E. Rubanov, and A. V. Yudin, “Anisotropy of the mechanical properties of austenitic steel products obtained by selective laser melting,” CIS Iron and Steel Review, 18, 64–68 (2019).

M. S. Bolkhovitin and A. V. Ionov, “Improving the quality of manufacture of die tooling for gas-turbine engine compressors,” Tr. MAI, No. 71, 15 (2013).

I. S. Safronov, I. V. Ushakov, and V. I. Minaev, “Influence of environment at laser processing on microhardness of amorphous nano crystalline metal alloy,” Mater. Sci. Forum, 1052, 50–55 (2022).

V. N. Shinkin, “Influence of non-linearity of hardening curve on elasticoplastic bend of rectangular rod,” CIS Iron and Steel Review, 17, 39–42 (2019).

A. V. Bronz, D. E. Kaputkin, L. M. Kaputkina, V. E. Kindop, and A. G. Svyazhin, “Influence of the composition on the lattice and physical properties of ferromanganese alloys with high aluminum content,” Metalloved. Term. Obrab. Metall., No. 12 (702), 11–15 (2013).

N. A. Chichenev, S. M. Gorbatyuk, M. G. Naumova, and I. G. Morozova, “Using the similarity theory for description of laser hardening processes,” CIS Iron and Steel Review, 19, 44–47 (2020).

A. A. Dmitrievskii, N. Yu. Efremova, and D. G. Guseva, “Quantitative assessment of the content of metastable phases of silicon Si-XII, Si-III, and α-Si in the indentation,” Izv. RAN, Ser. Fiz., 81, No. 11, 1522–1525 (2017).

A. V. Bronz, D. E. Kaputkin, L. M. Kaputkina, V. E. Kindop, and A. G. Svyazhin, “Mechanical and physical properties of cast Fe–Mn–Al–C–N alloys,” Izv. VUZov, Chern. Metallurg., 57, No. 11, 43-47 (2014).

N. B. Vargaftik, Handbook of Thermophysical Properties of Gases and Fluids [in Russian], Nauka, Moscow (1972).

W. S. Cleveland, “Robust locally weighted regression and smoothing scatterplots,” J. Amer. Stat. Assoc., 74, No. 368, 829–836 (1979).

A. V. Bokov, M. A. Korytova, and A. B. Samarov, “Numerical simulation of convective heat and mass transfer in spherical coordinates,” Vestn. YuUrGU, Ser. Mat. Model. Program., 12, 96–109 (2019).

E. V. Vorozhtsov and V. P. Shapeev, “Numerical solution of Poisson’s equation in polar coordinates by the method of collocations and minimum residuals,” Model. Analiz. Inform. Sist., 22, No. 5, 648–664 (2015).

A. A. Samarskii and A. V. Gulin, Numerical Methods of Mathematical Physics [in Russian], Nauchnyi Mir, Moscow (2003).

A. A. Samarskii and P. N. Vabishchevich, Numerical Methods for Solving Convection–Diffusion Problems [in Russian], URSS, Moscow (2009).

I. V. Ushakov and Yu. V. Simonov, “Using short-pulse laser radiation to control the physical and mechanical properties of the surface of titanium alloys,” Vestn. Moskov. Gos. Obl. Univ., Ser. Fiz.-Mat., No. 4, 30–42 (2019).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Metallurg, Vol. 67, No. 7, pp. 74–79, July, 2023.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Ushakov, I.V., Safronov, I.S., Oshorov, A.D. et al. Physics of the Effect of High-Temperature Pulse Heating On Defects in the Surface Layer of a Metal Alloy. Metallurgist 67, 986–994 (2023). https://doi.org/10.1007/s11015-023-01588-z

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11015-023-01588-z