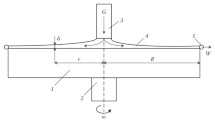

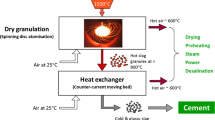

This article discusses the engineering and computational methodology of designing the main units of a blast-furnace slag dry granulation plant with a capacity of 1 million tons of slags per year, also intended for the recovery of slag heat. This plant can replace the slag wet granulation plant at blast furnace No. 5 at the iron and steel works of Severstal of the same capacity. The method can be used to estimate the radius and rotation frequency of the disk for spraying a slag, mechanical power to the disk drive, granulation chamber (GC) diameter that ensures the solidification of slag droplets, temperature of slag granules at the outlet of the GC, amount of heat transferred by convection to the air and by radiation to the walls of the GC, flow rate of air supplied to cool the slag, changes in the temperatures of the slag and air on fluidized bed grates (FBGs), size of these grates, loss of air pressure in the plant, and power consumption for the fan drive, amount of slag heat disposed of in the plant, and possible generation of electricity due to it. Recommendations on the shape of the side wall of the GC are given. The findings revealed that for a plant with a capacity of 1 million tons of slags per year with a diameter of granules no more than 2 mm, the disk radius should be approximately 0.2 m, with a rotation frequency of 500 rpm and disk drive power of 5.1 kW. The required diameter of the GC at the flight speed of slag droplets of 10.4 m/s is approximately 14.4 m. The slag is cooled in the GC from 1500℃ to 1030℃ and then to 150℃ on three FBGs. Cooling air with a flow rate of 34.8 nm3/s in FBGs is heated to 640℃ and then to 800℃ in the GC. The fan drive power for is approximately 40 kW. In the plant, approximately 43 MW of heat can be disposed for steam generation, and up to 18.5 MW of electricity can be obtained due to it.

Similar content being viewed by others

References

S. J. Pickering, N. Hay, T. F. Roylance, and G. H. Thomas, “New process for dry granulation and heat recovery from molten slag,” Ironmak. Steelmak., 12, No. 1, 14–21 (1985).

D. Xie, S. Jahanshali, and T. Norgate, Dry Granulation to Provide a Sustainable Option for Slag Treatment, In Proc. Sustainable Mining Conf., 22–28 (Kalgoorlie, Wa, Australia, 17–19 August, 2010).

H. Kappes and D. Michels, “Dry granulation of slag with energy recovery, from the idea generation to a pilot plant,” Chern. Metal., No. 5 (1001), 46–52 (2015).

H. Zhang, H. Wang, X. Zhu, Y. Qiu, K. Li, R. Chen, and Q. Liao, “A review of waste heat recovery technologies towards molten slag in steel industry,” Appl. Energy, 112, 956–966 (2013).

P. Yu, S. Wang, Y. Li, and G. Xu, A Review of Granulation Process for Blast Furnace Slag, MATEC Web of Conferences, The 3rd International Conference on Industrial Engineering and Applications ― ICIEA (Hong Kong, April 28–30, 2016), 68, 06–07 (2016).

S. V. Filatov, I. F. Kurunov, V. N. Titov, and S. A. Zagainov, “Implementation of energy-efficient solutions for iron smelting at NLMK,” Metallurg, No. 4, 25–28 (2019).

O. P. Onorin, A. A. Polinov, A. V. Pavlov, N. A. Spirin, and I. A. Gurin, “On the possibility of using the heat balance of blastfurnace smelting to control heat losses,” Metallurg, No. 3, 30–34 (2018).

E. G. Urbanovich, V. A. Panov, V. F. Voropaev, and V. I. Basov, “Heat losses with liquid blast-furnace slags and technical solutions for their reduction,” Izv. Vyssh. Ucheb. Zav. Chern. Metallurg., No. 7 (1303), 51–56 (2008).

L. A. Zainullin, D. V. Mekhryakov, V. G. Greznev, and Kai Chen, “Experience in the implementation of plants for furnace slag granulation according to the VNIIMT technology at blast furnaces with a capacity of 1260 and 4150 m3 in China,” Stal’, No. 3, 35–38 (2015).

A. S. Kadyrov, V. A. Kunaev, and I. V. Georgiadi, “Prospects for the processing of ferrous metallurgy waste on the example of ArcelorMittal Temirtau,” Metallurg, No. 1, 29–34 (2018).

S. V. Lukin, N. I. Shestakov, and E. M. Ilyicheva, “Heat transfer in the granulation chamber of a dry slag granulation unit,” Metallurg, No. 8, 36–41 (2019).

S. V. Lukin, A. V. Fokin, and E. M. Il’icheva, “Heat transfer on fluidized bed grates in a dry slag granulation unit,” Metallurg, No. 4, 16–20 (2020).

S. V. Lukin, N. I. Shestakov, E. M. Il’icheva, and A. V. Fokin, “Determination of the geometric and operating parameters of a device for spraying liquid slag in a dry slag granulation unit,” Metallurg, No. 3, 19–24 (2021).

D. N. Togobitskaya, A. I. Belkova, and A. F. Khamkhotko, “Experience in creation and implementation of a system for monitoring and control of the slag mode of blast-furnace smelting in the charge and technological conditions of Ukrainian plants,” Fundamental and Applied Problems of Ferrous Metallurgy, Proceedings, Dnepropetrovsk, IChM NAN Ukraine, 19, 100–112 (2009).

E. I. Kazantsev, Industrial Furnaces, Reference Book [in Russian], Metallurgiya, Moscow (1975).

B. P. Yuriev, “Study of the thermophysical properties of blast-furnace slags during their heat treatment,” Izv. Vyssh. Ucheb. Zav. Chern. Metallurg., No. 11, 5–10 (2014).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Metallurg, Vol. 66, No. 10, pp. 80–86, October 2022. Russian https://doi.org/10.52351/00260827_2022_10_80

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Lukin, S.V., Il’icheva, E.M. & Fokin, A.V. Design of a Dry Slag Granulation Plant for Blast Furnace No. 5 of Severstal. Metallurgist 66, 1273–1281 (2023). https://doi.org/10.1007/s11015-023-01441-3

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11015-023-01441-3