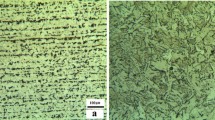

Comparative results are provided for Charpy V-notch impact bending tests of base metal and 09G2S steel welded joint metal before and after prolonged heat treatment (1200°C, 3.7 h exposure) with plotting of ductile–brittle transition curves and analysis of fracture surfaces after testing. Welded joints of 09G2S steel sheets with each other are prepared by automatic argon-arc welding with a consumable electrode in accordance with PNAE G-7-009-89. It is shown that in the temperature range from 200°С to room temperature impact strength of weld metal in the as-supplied condition is 2–2.5 times lower, and the beginning of ductile–brittle transition temperature is 90°С higher than for base metal. Long-term heat treatment expands the range of base metal ductile–brittle transition temperatures by 30°C and shifts the range of ductile–brittle transition temperatures in weld metal by at least 20°C towards higher temperatures.

Similar content being viewed by others

References

L. S. Livshits and A. N. Khakimov, Welded Joint Heat Treatment Science [in Russian], Mashinostroenie, Moscow (1989).

G. P. Fetisov, M. G. Karpman, and V. M. Matyunin, Material Science and Metal Technology [in Russian], Oniks, Moscow (2009).

Yu. V. Poletaev, V. Yu. Poletaev, and V. V. Shchepkin, “Friction welding of connecting pipes and small diameter joints of carbon steel 22k,” Vest. Don. Tekhn. Univ., No. 3, 89–95 (2017).

Yu. V. Poletaev, V. Yu. Poletaev, and A. É. Khubiev, “Single-pass electric arc welding beneath a thin layer of slag of thick sheet structures of steel 22K,” Svaroch. Proizvod, No. 5, 3–8 (2017).

I. N. Bogachev and V. F. Egolaev, Structure and Properties of Iron-Manganese Alloys [in Russian], Metallurgiya, Moscow (1973)

A. S. Zubchenko (editor), Steels and Alloy Grades [in Russian], Mashinostroenie, Moscow (2003).

C.-C. Yang and C.-L. Liu, “Improvement of the mechanical properties of 1022 carbon steel coil by using the Taguchi method to optimize spheroidized annealing conditions,” Materials, 9, 693 (2016).

É. L. Makarova (editor), Welding and Welding Materials, Vol. 1, Material Weldability, ref. ed. [in Russian], Metallurgiya, Moscow 91991).

N. A. Kozyrev, V. F. Igushev, R. E. Kryukov, and A. V. Roor, “Study of the effect of introducing carbon-containing additives into AN-67 flux on welded joint metal properties for steel 09G2S,” Izv. Vuz. Chern. Met., 56, No. 8, 33–36 (2013).

V. I. Bol’shakov, D. V. Laukhin, A. V. Beketov, A. V. Murashkin, and S. V. Ivantsov, “Effect of austenitic grain size on failure kinetics for high-strength structural steels,” Metallurg. Gorn. Prom, No. 1, 70–72 (2014).

M. V. Karasaev, V. G. Grebenchuk, V. S. Skutin, and R. Rozert, “Change in structure and impact strength of welded joint metal for low-carbon low-alloys steels type 09G2S, 15KhSND, 09G2FBYu after heat treatment at 610–650°C,” Svarka Diagnostika, No. 2, 20–27 92013).

G. L. Thinnes, G. E. Korth, and S. A. Chavez, “High temperature creep and tensile data for pressure vessel steels SA533B1 and SA508-CL2,” Nuclear Engineering and Design, 148, 343–350 (1994).

S. A. Nikulin, S. O. Rogachev, S. G. Vasil’ev, V. A. Belov, V. Yu. Turilina, and Yu. A. Nikolaev, “Effect of temperature on steel 22k mechanical properties,” Deform. Razrush. Materialov, No. 5, 22–26 (2020).

S. A. Nikulin, S. O. Rogachev, S. G. Vasil’ev, V. A. Belov, and Yu. A. Nikolaev, “Effect of high temperature on steel 09G2S mechanical properties,” Deform. Razrush. Materialov, No. 7, 32–35 (2020).

A. V. Kudrya, S. A. Nikulin, Yu. A. Nikoalaev, A. M. Arsenkin, É. A. Sokolovskaya, S. V. Skorodumov, A. A. Chernobaeva, E. I. Kuz’ko, and E. G. Khoreva, “Inhomogeneity factors of low-alloy steel 15Kh2NMFA toughness,” Izv. Vuz. Chern. Met., No. 9, 23–28 (2009).

S. A. Nikulin, A. V. Kudrya, É. A. Sokolovskaya, S. V. Skorodumov, É. V. Li, E. I. Kuz’ko, T. Sh. Salikov, and A. M. Arsenkin, “Steel 15Kh2NMFA brittleness factors after annealing in the temperature range for reverse temper brittleness,” Metallurg, No. 10, 72–76 (2011).

Yu. N. Saraev, N. I. Golikov, V. V. Dmitriev, I. I. Sannikov, V. P. Bezborodov, and A. A. Grigor’eva, “Study of the effect of additive pulsed-arc welding of steel 09G2S joints,” Obrabotka Metallov (Tekhnol, Oborud. Instrumenty), No. 3 (60), 19–24 (2013).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Metallurg, Vol. 65, No. 12, pp. 39–46, December, 2021. Russian DOI: https://doi.org/10.52351/00260827_2021_12_39.

Rights and permissions

About this article

Cite this article

Nikulin, S.A., Rogachev, S.O., Belov, V.A. et al. Impact Strength of Low-Carbon Steel 09G2S Welded Joint Metal. Metallurgist 65, 1391–1400 (2022). https://doi.org/10.1007/s11015-022-01286-2

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11015-022-01286-2