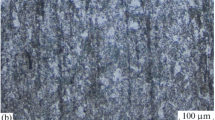

This study examined how the strength characteristics of steel can be improved through induction surfacing. Different types of base and surfacing substances were analyzed. The macrophotographs of the treated steel surface were obtained using various methods, and the phases on the steel surface were determined. The microhardness of the different phases was determined. Results suggested that induction surfacing could improve the wear resistance of the samples.

Similar content being viewed by others

References

S. K. Alias, M. N. Halmy, and M. A. Shah, “Effect of surface attrition on hardness on the hardness and wear properties of 304 stainless steels. IOP Conf. Ser.,” Mater. Sci. Eng., 834, Art. 012058 (2020).

Z. Wen and K. Dejun, “Effects of laser thermal sprayed AlNiCr coating on fatigue performances of S355 structural steel,” Int. J. Fatigue, 131, Art. 105359 (2020).

Y. J. Zhou, Y. Zhang, F. J. Wang, Y. L. Wang, and G. L. Chen, “Effect of Cu addition on the microstructure and mechanical properties of AlCoCrFeNiTi0.5 solid-solution alloy,” J. Alloys Compd., 466, No. 1-2, 201–204 (2008).

V. M. Kishurov, V. N. Ippolitov, and M. V. Kishurov, “Increasing the life of coated high-speed steel tools,” Russ. Eng. Res., 33, No. 12, 727–730 (2013).

D. A. Ivanov and O. N. Zasukhin, “Processing of tool steels with pulsating gas flows,” Tekhnolog. Metall., No. 9, 39–43 (2016).

Jien-Wei Yeh, Shou-Yi Chang, Yu-Der Hong, Swe-Kai Chen, and Su-Jien Lin, “Anomalous decrease in X-ray diffraction intensities of Cu–Ni–Al–Co–Cr–Fe–Si alloy systems with multiprincipal elements,” Mater. Chem. Phys., 103, No. 1, 41–46 (2007).

S. S. Mahlalela and P. G. H. Pistorius, “Microstructural characterization of laser beam and gas tungsten arc welded zirconium-2.5Nb,” J. S. Afr. Inst. Min. Metall., 117, No. 10, 947–953 (2017).

X.-L. Gao, J. Liu, L.-J. Zhang, and J.-X. Zhang, “Effect of the overlapping factor on the microstructure and mechanical properties of pulsed Nd: YAG laser welded Ti6Al4V sheets,” Mater. Character., 93, 136–149 (2014).

Q. Wan, X. Bai, and X. Zhang, “Impact of high dose krypton ion irradiation on corrosion behavior of laser beam welded Zircaloy-4,” Mater. Res. Bull., 41, No. 2, 387–395 (2006).

D. H. Jeong and J. H. Kim, “Fatigue characteristics of laser welded Zircaloy thin sheet,” Int. J. Mod. Phys.: Conf. Ser., 6, 367–372 (2012).

Q. Han, D. Kim, D. Kim, H. Lee, and N. Kim, “Laser pulsed welding in thin sheets of Zircaloy-4,” J. Mater. Process. Technol., 212, 1116–1122 (2012).

S. A. Sidorov, Y. P. Lobachevskii, V. K. Khoroshenkov, T. S. Akhmedova, and D. A. Vorob’ev, “Improving wear resistance of agricultural machine components by applying hard-alloy thick-layer coatings using plasma surfacing,” Metallurgist, 60, No. 11-12, 1290–1294 (2016).

A. S. Mel’nichenko, A. V. Kudrya, T. S. Akhmedova, and E. A. Sokolovskaya, “Predicting the risk of destruction of hard-facing alloys based on the morphology of their structure,” Metallurgist, 61, No. 11-12, 1130–1134 (2017).

S. Dmitriev, V. Malikov, and A. Ishkov, “Investigation of thermal fields at phase boundaries in powder mixtures that are subject to melting and chemical transformation,” Mater. Sci. Forum, 992 MSF, 1011–1015 (2020).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Metallurg, Vol. 65, No. 11, pp. 69–75, November, 2021. Russian DOI: https://doi.org/10.52351/00260827_2021_11_69.

Rights and permissions

About this article

Cite this article

Malikov, V.N., Ishkov, A.V., Voinash, S.A. et al. Investigating Induction-Surfacing Processes for Hardening Steel Parts. Metallurgist 65, 1289–1298 (2022). https://doi.org/10.1007/s11015-022-01275-5

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11015-022-01275-5