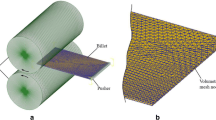

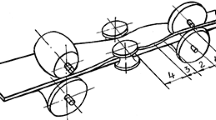

We consider the operation of an existing cooling system for the rolls of a 1950 wide-strip hot-rolling mill aimed at the production of thin-sheet strips. On the basis of the results of computer simulation of this cooling system, we propose a new scheme for the supply of coolants. This system enables one to reduce thermal stresses on the surfaces of rollers, to improve the quality, and to decrease the thickness of hot-rolled thin-sheet steel from 1.3 mm to 1 mm.

Similar content being viewed by others

References

J. Bast, S. M. Gorbatyuk, and I. Yu. Kryukov, “Horizontal hcc-12000 unit for the continuous casting of semifinished products,” Metallurgist,55, Issues 1–2, 116–118 (2011), DOI: https://doi.org/10.1007/s11015-011-9399-1.

A. N. Zakharov, S. M. Gorbatyuk, and V. G. Borisevich, “Modernizing a press for making refractories,” Metallurgist,52, 420–423 (2008); DOI: https://doi.org/10.1007/s11015-008-9072-5.

A. M. Keropyan, L. I. Kantovich, B. V. Voronin, D. A. Kuziev, and V. V. Zotov, “Influence of uneven distribution of coupling mass on locomotive wheel pairs, its tractive power, straight and curved sections of industrial rail tracks,” IOP Confer. Series: Earth and Environmental Science,87(6), No. 062005 (2017); DOI: https://doi.org/10.1088/1755-1315/87/6/062005.

A. D. Bardovskiy, S. M. Gorbatyuk, A. M. Keropyan, and P. Y. Bibikov, “Assessing parameters of the accelerator disk of a centrifugal mill taking into account features of particle motion on the disk surface,” J. Friction Wear,39(4), 326–329 (2018 ); DOI: https://doi.org/10.3103/S1068366618040037.

A. Bardovsky, A. Gerasimova, and A. Aydunbekov, “The principles of the milling equipment improvement,” MATEC. Web of Confer.,224, No. 01019 (2018); DOI: https://doi.org/10.1051/matecconf/201822401019.

S. I. Platov, R. R. Dema, M. V. Zubareva, and I. M. Yachikov, “Analysis of the thermal state of mill rolls aimed at the improvement of the temperature conditions of their operation,” in: V. M. Salganik (editor), Modeling and Development of Processes of Treatment of Metals by Pressure, A Collection of Research Papers [in Russian], Magnitogorsk State Technical University, Magnitogorsk (2011), pp. 25–30.

https://omk.ru (03.11.18).

D. Hajduk, J. Horsky, and M. Raudensky, “Control of ISC on hot strip mill,” in: Proc. of the 7th Intern. Conf. on Steel Rolling, Iron and Steel Institute, Chiba (2006), ISBN 80-239-7750-4.

S. M. Gorbatyuk, V. M. Pavlov, A. N. Shapoval, and M. S. Gorbatyuk, “Experimental use of rotary rolling mills to deform compacts of refractory metals,” Metallurgist,42, Issues 5-6, 178–183 (1998); DOI: https://doi.org/10.1007/BF02766359.

V. S. Parshin, A. P. Karamyshev, I. I. Nekrasov, A. I. Pugin, and A. A. Fedulov, A Practical Guide to the DEFORM-3D Software Complex [in Russian], Ural Federal University, Ekaterinburg (2010).

A. K. Ray, K. K. Mishra, P. N. Chaudhary, et al., “Failure analysis of rolls of cold rolling mill in steel plant,” Eng. Failure Anal.,4, 37–46 (1997).

S. M. Gorbatyuk, A. A. Gerasimova, and N. N. Belkina, “Applying thermal coatings to narrow walls of the continuous-casting molds,” Mater. Sci. Forum,870, 564–567 (2016); DOI: https://doi.org/10.4028/www.scientific.net/MSF.870.564.

A. Yu. Zarapin, I. A. Levitskij, A. S. Mokretsov, and N. A. Chichenev, “Modeling of rolling the three-layer bands with resistance heating,” Steel Transl.,7, 61–64 (1999).

E. A. Mazhirin, N. A. Chichenev, and V. D. Zadorozhnyi, “Modernizing the track units of the 2800 thick-sheet mill at J.-S.C. Ural’skaya Stal,” Steel Transl.,38 (12), 1048–1050 (2008); DOI: https://doi.org/10.3103/S0967091208120255.

P. I. Polukhin, A. Henzel, V. P. Polukhin, et al., Technology of the Processes of Pressure Treatment of Metals [in Russian], Metallurgiya, Moscow (1988).

M. M. Saf’yan, V. L. Mazur, A. M. Saf’yan, et al., Technology of the Processes of Rolling and Drawing. Sheet-Rolling Production [in Russian], Vysshaya Shkola, Kiev (1988).

Yu. F. Shevakin and V. S. Shaikevich, Pressure Treatment of Metals [in Russian], Metallurgiya, Moscow (1972).

N. B. Ganin, Three-Dimensional Projection in KOMPAS-3D [in Russian], DMK-Press, Moscow (2012).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Metallurg, Vol. 63, No. 8, pp. 59–62, August, 2019.

Rights and permissions

About this article

Cite this article

Gorbatyuk, S.M., Romanov, S.P. & Morozova, I.G. Computer Simulation of the Cooling System for Rollers of the Finishing Stand of a Wide-Strip Hot-Rolling Mill and the Development of a New Scheme of Cooling. Metallurgist 63, 836–840 (2019). https://doi.org/10.1007/s11015-019-00897-6

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11015-019-00897-6