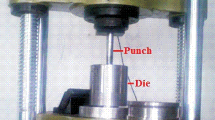

A hot-pressing technology for producing aluminum-based metal-matrix composite materials used to manufacture liquid-cooled base plates of electronic modules of active phased antenna arrays (APAA) was developed and tested. The technology involves the following operations: mixing of the starting components, adding of a binder, forming of blanks, hot pressing of the blanks, sintering in a controlled atmosphere, grinding of the sintered blanks, cutting of the blanks to size, coating, and controlling of the material parameters. The curves of the density of SiC–Al composite material versus the isothermal-holding time and the compaction pressure are plotted. It is established that combining hexagonal silicon carbide (6H α-SiC) and aluminum alloy with a silicon content of 7–12%, it is possible to obtain a SiC–Al composite with a thermal conductivity of up to 240 W/(m·K).

Similar content being viewed by others

References

M. A. Occhioner, R. A. Hay, R. W. Adams, and K. P. Fennessy, “Aluminum silicon carbide (AlSiC) thermal management packaging for high density packaging applications,” in: Proc. of SPIE, January (1999), pp. 1–6.

L. K. Bolotova, I. E. Kalashnikov, T. V. Korzh, and T. A. Chernyshova, “Methods of examination in compositions of a metal matrix and SiC particles or whiskers,” Adgez. Raspl. Paika Mater., No. 31, 69–73 (1994).

C. Yan, W. Lifeng, and R. Jianyue, “Multi-functional SiC/Al. Composites for aerospace applications,” Chinese J. Aeronautics, 21, 578–584 (2008).

R. Cheung, Silicon Carbide Microelectromechanical Systems for Harsh Environments, Imperial College Press (2006).

V. Sikulskiy, V. Kashcheyeva, Yu. Romanenkov, and A. Shapoval, “Study of the process of shape-formation of ribbed doublecurvature panels by local deforming,” Eastern-Europ. J. Enterpr. Technol., 4, No. 1 (88), 43–49 (2017), https://doi.org/10.15587/1729-4061.2017.108190.

V. Dragobetskii, A. Shapoval, E. Naumova, et al., “The technology of production of a copper–aluminum–copper composite to produce current lead buses of the high-voltage plants,” in: IEEE Int. Conf. on Modern Electrical and Energy Systems (MEES) (2017), pp. 400–403, https://doi.org/10.1109/MEES.2017.8248944.

A. Yu. Zarapin, A. I. Shur, and N. A. Chichenev, “Improvement of the unit for rolling aluminum strip clad with corrosion-resistant steel,” Steel in Transl., 29, No. 10, 69–71 (1999).

A. Yu. Zarapin, I. A. Levitskii, A. S. Mokretsov, and N. A. Chichenev, “Modeling the rolling of three-layer bands using resistance heating and electroplastic deformation,” Stal, No. 7, 61–64 (1999).

A. Yu. Zarapin and A. N. Chichenev, “Designing lines for the production of composite materials, based on the object-oriented approach,” Tyazh. Mashinostr., No. 6, 16–20 (1999).

S. M. Gorbatyuk, S. M. Pavlov, and A. N. Shapoval, “Experience in application of screw rolling mill for deforming the billets of refractory metals,” Metallurg., No. 5, 32–35 (1998).

O. A. Kobelev, M. A. Tsepin, M. M. Skripalenko, and V. A. Popov, “Features of technological layout of manufacture of unique mono-block large-dimension plates,” Adv. Mater. Res., 59, 71–75 (2009), https://doi.org/10.4028/3-908454-01-8.71.

A. D. Bardovskiy, S. M. Gorbatyuk, A. M. Keropyan, and P. Y. Bibikov, “Assessing parameters of the accelerator disk of a centrifugal mill taking into account features of particle motion on the disk surface,” J. Frict. Wear, 39, No. 4, 326–329 (2018).

L. S. Kokhan, I. G. Roberov, Y. A. Morozov, and A. V. Borisov, “Rolling with simultaneous pressing of the reduced plate,” Steel in Transl., 39, No. 7, 533–536 (2009).

I. G. Roberov, L. S. Kokhan, Y. A. Morozov, and A. V. Borisov, “Stamping complex surfaces by rolling,” Steel in Transl., 39, No. 1, 11–14 (2009).

J. Bast, S. M. Gorbatyuk, and I. Yu. Kryukov, “Horizontal HCC-12000 unit for the continuous casting of semifinished products,” Metallurgist, 55, No. 1–2, 116–118 (2008), https://doi.org/10.1007/ s11015-011-9399-1.

G. A. Pimenov, G. A. Kostyukov, P. S. Ryabov, V. D. Rogal’, and O. A. Kobelev, “Making of large-sized solid-forged blanks,” Tyazh. Mashinostr., No. 9, 21–24 (1991).

A. G. Nalogin and A. N. Pashkov, Development of a SiC–Al Composite Material and Formulation, Based on Its Properties, of Requirements to Dies for Producing Base Plates with Minimum Machining Allowance, R&D Report, Topic Code: Komplektsiya-5-Kompozit, Fryazino (2012).

N. P. Litvinenko and Yu. D. Chistyakov, Soldering of Aluminum and Its Alloys in Electronic Engineering. Reviews on Electronic Engineering, Ser.: Technology, Process Management, Equipment, Issue 14 (1066), TsNII Elektronika, Moscow (1984).

T. A. Chernyshova, R. S. Mikheev, I. E. Kalashnikov, et al., “Development and testing of Al–SiC and Al–TiC composite materials for application in friction units of oil-production equipment,” Inorg. Mater.: Appl. Res., 2, No. 3, 282–289 (2011).

A. N. Pashkov, Development and Study of the Production of Metal-Matrix Composite Materials by Forming, PhD Thesis, Moscow (2017).

M. A. Occhioner, R. A. Hay, R. W. Adams, and K. P. Fennessy, “Aluminum silicon carbide (AlSiC) thermal management packaging for high density packaging applications,” in: Proc. of SPIE (1999), pp. 1–6.

A. G. Nalogin, A. N. Pashkov, and S. M. Gorbatyuk, “Making prototypes of SiC–Al composite material by hot pressing,” Elektr. Tekhn., Ser. 1: SVCh-Tekhnika, No. 2 (533), 6–11 (2017).

A. G. Nalogin and A. N. Pashkov, A Method for Producing a Composite Material for Microwave Engineering, Patent No. 2625377 RF, IPC H02H9/06, Appl. June 1 (2016); Byul. No. 20, Publ. July 13 (2017).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Metallurg, Vol. 62, No. 12, pp. 54–58, December, 2018.

Rights and permissions

About this article

Cite this article

Gorbatyuk, S.M., Pashkov, A.N., Zarapin, A.Y. et al. Development of Hot-Pressing Technology for Production of Aluminum-Based Metal-Matrix Composite Materials. Metallurgist 62, 1261–1266 (2019). https://doi.org/10.1007/s11015-019-00784-0

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11015-019-00784-0