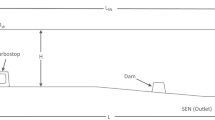

Physical modeling of metal flows in a continuous casting machine tundish of the ESSW of AO VTZ is conducted. It is established that the existing tundish design does not allow non-metallic inclusions to float sufficiently and be assimilated by slag, which leads to clogging of the submerged nozzle and a reduction in C45E steel castability. Technical solutions for changing the geometric parameters of the tundish and tundish turbostop are proposed and implemented from results of simulation, including an increase in tundish depth and use of a turbostop of original construction. The technical solutions developed make it possible to increase the degree of non-metallic inclusion assimilation by the tundish slag cover, both at the start and throughout an entire series of casting, and also to reduce submerged nozzle clogging during casting steel C45E by a factor of 5.9.

Similar content being viewed by others

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Metallurg, Vol. 62, No. 12, pp. 39–41, December, 2018.

Rights and permissions

About this article

Cite this article

Bozheskov, A.N., Alenin, A.V., Kazakov, V.V. et al. Physical Modeling of Metal Flows in an AO Volga Pipe Plant ESSW CBCM-2 Tundish with the Aim of Improving its Construction. Metallurgist 62, 1240–1243 (2019). https://doi.org/10.1007/s11015-019-00780-4

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11015-019-00780-4