An increase in the wear resistance of soil cultivating equipment components by applying a hard-alloy coating is often used in practice. The good wear resistance of hard alloys is provided, in particular, by the presence of tungsten carbide within them. However, a lack of evaluation of the resistance of these alloys to breakage and life under operating conditions limits their extensive propagation (alongside cost). Results are given in this work for laboratory and operating tests of hard alloys with added tungsten carbide (in combination with hard alloys based on iron and nickel) on wear resistance, and the alloy breakage mechanism with plasma surfacing on soil cultivating machine tool components is evaluated.

Similar content being viewed by others

References

S. A. Sidorov, Increase in the Endurance and Operating Capacity of Soil Cultivation Machine Tools and Equipment Used in Agriculture and Forestry: Diss. Doc. Techn. Sci., VISKhOM, Moscow (2007).

A. Yu. Izmailov, S. A. Sidorov, Ya. P. Dobachevskii, et al., “Scientific principles of improving the wear resistance of working tools of soil cultivators,” Vestn. Ros. Selskokhoz. Nauki, No. 3, 5–7 (2012).

A. Khasui and O. Morigaki, Surfacing and Atomization [Russian translation], Mashinostronie, Moscow (1985).

G. I. Glushkov, Technology of Hard Alloy Coating of Rapidly Wearing Components, ONTI-NKTP-SSSR, Leningrad (1935).

S. A. Sidorov, D. A. Mironov, V. K. Khoroshenkov, and E. I. Khlusova, “Surfacing meethods for improving the life of rapidly wearing agricultural machine working tools,” Svaroch. Proizv., No. 10, 35–40 (2015).

S. A. Sidorov, “Agricultural machine engineering – high quality materials,” Selsk. Mashin. Tekhnol., No. 2, 41 (2010).

HETILL: Selbstscharffnde Bodenbearbende Bodenbe Bodenbearbeitungs-Werkzeuge. Technologie zur Auftragung von Hartstoffe. Schneidenranten Konstruktion für Werkzeuge. Werkstoff für die Artaufragung, Advertising preprint of INNOWELD, Austria (2004).

Metallurgical Powders, Polema, Tula (2014).

INNOSTEL 1, INNOSTELF, Firm advertising preprint, INNOWELD, Austria (1999).

Strength Guarantee – Life Guarantee, Advertising preprint of iQ Parts (Austria), TEKhNO-SNAB, Kamenka (2016).

S. A. Sidorov, V. K. Khoroshenkov, Ya. P. Dobachevskii, and T. Sh. Akhmetova, “Increase in wear resistance of hard alloy thick layer coatings by plasma deposition on agricultural machine components,” Metallurg, No. 12, 81–84 (2016).

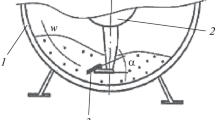

S. A. Sidorov, D. A. Mironov, and I. V. Diskin, Patent 2613292 RF, IPC G01N3/56, “Round soil test unit,” subm. 12.17.2015, publ. 03.15.2017.

L. I. Kuksenova, Structural Steel Wear Resistance, Izd. MGTU. im. Baumana, Moscow (2011).

M. A. Stremel, Failure, Vol. 2, Structural Failure, ID MISiS, Moscow (2015).

E. A. Sokolovskaya, “Reproducibility of results for measuring structure and fractures using computerized procedures,” Vopr. Materialoved., No. 4 (76), 143–153 (2013).

M. A. Stremel, Failure, Vol. 1, Material Failure, ID MISiS, Moscow (2014).

A. V. Kudrya, E. A. Sokolovskaya, T. Sh. Akhmedova, and V. Yu. Perezhogin, “Inhomogeneity of structure and failure of hard alloys based on iron and measurement,” Elektrometallurgiya, No. 6, 32–40 (2017).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Metallurg, No. 11, pp. 96–100, November, 2017.

Rights and permissions

About this article

Cite this article

Sidorov, S.A., Lobachevskii, Y.P., Khoroshenkov, V.K. et al. Wear and Breakage Resistance of Hard Alloy Coatings Strengthened with Tungsten Carbide. Metallurgist 61, 1023–1028 (2018). https://doi.org/10.1007/s11015-018-0602-5

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11015-018-0602-5