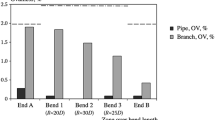

Results are given for evaluation of the effect of longitudinal deformation on the change of the mechanical properties and steel properties with a two-phase pipe metal structure previously given low-temperature heat treatment simulating application of an anticorrosion coating. A reduction in steel deformation capacity to the minimum permissible level is evaluated by a criterion δun ≥ 3% and σy(Rt0.5)/σu ≤ 0.96–0.98. As a result of testing plates subjected to longitudinal tension with plastic deformation εp = 1.5–7.0%, it is shown that exhaustion of steel deformation capacity is predicted in the transverse direction with preliminary deformation εp ≈ 5%, and in the longitudinal direction with εp ≈ 4–5%. SEM and TEM methods are used to study the effect of steel main structural characteristics whose presence facilitates retention of capacity for steel strain hardening after heating (200–220°C, 5 min): fine islands of twinned martensite, fine cementite particles and abundant precipitation of nanosize particles of Nb and V carbonitrides. During branch pipe bending deformation (εp ≤ 3.0%) in a two-phase steel structure (main components are ferrite and lath martensite) includes transformation of residual austenite from the MA-component in twinned martensite.

Similar content being viewed by others

References

R. Denys, W. De Waele, A. Lefevre, and P. De Baets, “Plastic straining capacity of axially-loaded pipelines: experimental facts and critical considerations,” Proc. 4th Int. Conf. on Pipeline Technology, Ostend, Belgium, Scientific Surveys Ltd., UK (2004), Vol. 1, pp. 183–207.

N. Ishikawa, M. Okatsu, and D. Kondo, “Development of high-strength pipes for main pipelines designed for operation in severe geological-climatic conditions,” Nauka Tekhn. Gaz. Prom., No. 1, 92–99 (2009).

C. Hongyuan, J. Lingkang, X. Qingren, et al., “Strainbased design of pipelines – requirements on materials related to compressive capacity,” Proc. HSLP 2010: Int. Seminar on Application of High Strength Line Pipe 2010, Xi’an, China, June 28–29, 2010.

E. Tsuru, T. Hara, Y. Shinohara, et al., “Development of high-deformability, high-strength line pipes for ultralow-temperature use,” Nippon Steel & Sumitomo Metal Techn. Rep., No. 107, 44–51 (2015).

I. P. Shabalov, S. Yu. Nastich, V. Ya. Velikodnev, et al., “Effect of heating and deformation on highly deformed pipe metal properties during cold-bent branch pipe manufacture,” Metallurg, No. 10, 63–71 (2016).

I. P. Shabalov, V. Ya. Velikodnyev, S. Yu. Nastich, et al., “Change in pipe properties o strength class K60 with increased deformation capacity during cold-bent branch pipe manufacture,” Proc. 22nd Int. Conf. Pipes-2016: Electron. Paper Coll., Chelyabinsk, 09.20–22.2016, RosNITI, Chelyabinsk (2016).

Y. Terada, A. Kojima, T. Hara, et al., “Recent development of high-strength linepipes in hostile environments,” Proc. 4th Int. Conf. on Pipeline Technology, Ostend, Belgium, in: Sci. Surveys Ltd., UK, 4, 1603–1617 (2004).

T. Hara, Y. Shinohara, Y. Terada, et al., “Metallurgical design and development of high deformable high strength line pipe suitable for strain-based design,” Proc. 19th Int. Offshore and Polar Engineering Conf., Osaka, Japan, June 21–26, 2009, pp. 73–79.

J. Shimamura, N. Ishikawa, S. Endo, et al., “Development of heavy wall X70 high strain linepipe steel,” Proc. 23rd Int. Offshore and Polar Engineering Conf., Anchorage, Alaska, USA, June 30–July 5, 2013, pp. 37–43.

A. V. Nokhrin and V. N. Chuvildeev, “Ageing of main gas pipeline steel pipes,” Vestn. Nizhegorod. Univ. im. Lobachevskogo, No. 5(2), 171–180 (2010).

M. A. Smirnov, I. Yu. Pyshmintsev, O. V. Varnak, et al., “Study of low-carbon steel inclination towards strain ageing and Bauschinger effect,” Stal, No. 1, 39–45 (2016).

H. Lee, X. Wu, Y. M. Kim, and N. J. Kim, “Effect of second phase on mechanical properties of bainite-base steels,” Adv. Mater. Res. (Trans. Tech. Publications) 15–17, 780–785 (2007).

L. I. Efron, Material Science in “Large” Metallurgy. Pipe Steels, Metallurgizdat, Moscow (2012).

G. G. Vasil’ev and T. V. Elagina, “Desirability of considering the effect of yield strength to ultimate strength ratio in selecting pipes for construction under complex conditions,” Truboprov. Transp., No. 5(39), 34–38 (2013).

M. Yu. Matrosov, I. V. Lyasotskii, A. A. Kichkina, et al., “Features and classification of structures of low-carbon low-alloy high-strength pipe steels,” Stal, No. 1, 65–74 (2012).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Metallurg, No. 8, pp. 75–82, August, 2017.

Rights and permissions

About this article

Cite this article

Shabalov, I.P., Nastich, S.Y., Velikodnev, V.Y. et al. Change in Properties of Pipe Steel with Two-Phase Structure During Low-Temperature Heating and Subsequent Plastic Deformation. Metallurgist 61, 686–693 (2017). https://doi.org/10.1007/s11015-017-0550-5

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11015-017-0550-5