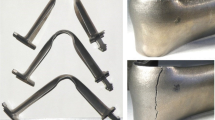

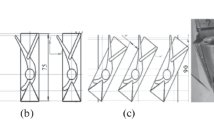

Under conditions of Klimov engineering enterprise, industrial results are obtained for the first time for developing casting technology for small single-crystal uncooled GTE turbine rotor blades of a new heatresistant alloy VZhM7 with reduced density and with a crystal orientation of <001>. Structural models are developed for blocks of blades with seeds and heat-resistant alloy melting and pouring in a unit for directional solidification. Test batches of blade castings are obtained with a yield of finished single-crystal structure of not less than 90% under VIAM pilot plant conditions, and 80% under conditions of Klimov engineering enterprise. The structure and phase properties are given for single-crystal blade material after casting, hot isostatic pressing, and subsequent heat treatment. Data are provided for fatigue tests on blades with crystal orientation <001>.

Similar content being viewed by others

References

Yu. A. Nozhnitskii, “Structural technological appearance of rotor blades of future high-temperature GTE turbines,” in: New Production Processes and GTE Reliability, Iss. 7, Provision of Strength Reliability for High-Temperature Turbine Rotor Blades, TsIAM, Moscow (2008), pp. 3–7.

E. M. Kablov, “Innovative developments of FGUP VIAM GNTs RF for implementing “Strategic areas of developing materials and technology and processing in the period up to 2030,” Aviats. Mater. Tekhnol., No. 1(34), 3–33 (2015).

S. Walston, A. Cetel, R. Mac Kay, et al, “Joint development of a fourth generation single crystal superalloy,” in: Superalloys 2004, Minerals, Metals & Materials Society, Pennsylvania (2004), pp. 15–24.

H. Harada, “Development of Superalloys for 1700°C ultra-efficient gas turbines:,” in: Proc. 9th Liege Conf. Materials for Advanced Power Engineering 2010, Univ. Liège, Belgium (2010), pp. 604–614.

E. N. Kablov, N. V. Petrushin, and I. L. Svetlov, “Computer construction of fourth generation nickel-base superalloy for gas turbine single-crystal blades,” in: Cast Heat-Resistant Alloys. S. T. Kishkin Effect, Nauka, Moscow (2006), pp. 98–115.

E. N. Kablov, N. V. Petrushin, and E. S. Elyutin, “Single-crystal heat-resistant alloys for gas turbine engines,” Vestn. MGTU im. Baumana, Ser. Mashinostr., No. Sp.2, 38–52 (2011).

E. N. Kablov, O. G. Ospennikova, N. V. Petrushin, and E. M. Visik, “Single-crystal nickel-base superalloys of a new generation with low density,” Aviats. Mater. Tekhnol, No. 2(35), 14–25 (2015).

E. N. Kablov, I. L. Svetlov, and M. V. Petrushin, “Nickel-base superalloys fro casting blades with directional and single-crystal structures. Part 1,” Materialovendenie, No. 4, 32–39 (1997).

N. V. Perrushin, O. G. Ospennikova, and E. S. Elyutin, “Rhenium in single-crystal nickel-base superalloys for gas turbine engine blades,” Aviats. Mater. Tekhnol., No. S5, 5–16 (2014).

E. N. Kablov, I. L. Svetlov, and N. V. Petrushin, “Nickel-base superalloys containing rhenium,” in: Aviation Materials and Technology, Iss.: High Rhenium Heat-Resistant Alloys, Technology, and Equipment for Producing Alloys and Castings Single-Crystal GTE Turbine Blades, VIAM, Moscow (2004), pp. 80–90.

N. V. Petrushin, O. G. Ospennikova, E. N. Visk, et al., “Nickel-base superalloys with low density,” Lit. Proizvod., No. 6, 5–11 (2012).

E. N. Kablov, O. G. Ospennikova, and N. V. Petrushin, “New single-crystal intermetallic heat-resistant alloy based on γ′-phase for GTE blades,” Aviats. Mater. Tekhnol., No. 1(34), 34–40 (2015).

N. A. Sharova, E. A. Tikhomirova, A. L. Barabash, et al., “Choice of nickel-base superalloys for prospective aviation GTE,” Vestn. Samar. Gos. Aerokos. Univ, No. 3(19) 249–255 (2009).

E. N. Kablov, Yu. V. Gerasimov, E. M. Visik, and I. M. Demonis, “Role of directional solidification in resource saving technology for manufacturing GTE components,” Tr. VIAM, No. 3, Art. 01 (2013), http://www.viam.works.ru.

E. M. Visik and V. V. Gerasimov, “Study of the effect of thermal conditions during directional solidification on structural parameters of intermetallic alloy VKNA-4UMono,” Metallurg, No. 11, 99–104 (2013).

A. I. Epishin, I. L. Svetlov, N. V. Petrushin, et al., “Segregation in single crystal nickel-base superalloys,” Defect and Diffusion Forum, 309/310, 121–126 (2011).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Metallurg, No. 2, pp. 80–86, February, 2017.

Rights and permissions

About this article

Cite this article

Visik, E.M., Tikhomirova, E.A., Petrushin, N.V. et al. Production Trial of a New Heat-Resistant Alloy with Low Density with Single-Crystal GTE Blade Casting . Metallurgist 61, 162–169 (2017). https://doi.org/10.1007/s11015-017-0470-4

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11015-017-0470-4