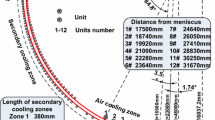

Modeling is conducted for solidification and formation of a cast structure of continuously-cast blooms of steel GCr15 (Russian analog is steel ShKh15). A finite element method is used in order to model the formation of the crystal structure of continuously-cast blooms. Solidification is modelled for a bloom of steel GCr15 470 × 350 mm in cross section with different values of steel overheating above the liquidus line. Results of modeling are used for simulating continuously-cast billet macrostructure. It is shown that with a reduction in casting temperature the extent of the columnar crystal zone is reduced gradually within the structure, the extent of the skin and equiaxed zones is expanded, grain density increases gradually, and the maximum grain area and radius are significantly reduced. There are no small size fine dendritic crystals within the center of the equiaxed grain zone.

Similar content being viewed by others

References

M. Rappaz and C. A. Gandin, “Probabilistic modeling of microstructure formation in solidification process,” Acta Mater., 41, 345–360 (1993).

W. Kurz, B. Giovanola, and R. Trivedi, “Theory of microstructural development during rapid solidification,” Acta Metall., 34, 823–830 (1986).

L. Nastac and D. M. Stefanescu, “Stochastic modeling of microstructure formation in solidification processes,” Model. Simul. Mater. Sci. Eng., 5, 391–398 (1997).

K. Kremeyer, “Cellular automation investigations of binary solidification,” Comput. Phys., 142, 243–262 (1998).

C. A. Gandin and J. L. Desbiolles, “A three-dimensional cellular automaton-finite element model for the prediction of solidification grain structures,” Metall. Trans. A, 30, 3153–3165 (1999).

Y. Y. Li, D. Z. Li, and M. Y. Zhu, Computer Simulation of Metal Processing, Science Press, Beijing (2006).

G. X. Hu and X. Cai, Materials Science Foundation, Shanghai Jiaotong Univ. Press, Shanghai (2005).

Ch.-A. Gandin and M. Rappaz, “A couple finite element-cellular automaton model for the prediction of dendritic grain structure in solidification process,” Acta Metall. Mater., 40, 2233–2238 (1994).

J. Miettinen, “Thermodynamic-kinetic simulation of constrained dendrite growth in steels,” Metall. Trans. B, 31B, 365–371 (2000).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Metallurg, No. 1, pp. 46–51, January, 2017.

Rights and permissions

About this article

Cite this article

Xu, D., Liu, H., Peng, C. et al. Effect of Casting Temperature on Continuously-Cast Bearing Steel GCr15 Billet Structure Formation. Metallurgist 61, 19–25 (2017). https://doi.org/10.1007/s11015-017-0448-2

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11015-017-0448-2