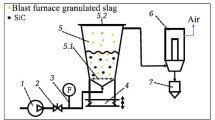

A procedure is described for qualitative evaluation of the effect of binders on granulated slag-forming mixture (SFM) strength. A relationship is established for slip density and finished granulate bulk density on water content. Industrial tests are conducted for a new binder and a test batch of granulated SFM is prepared with a low proportion of dusty fraction for pouring steel in a CBCM at MMK.

Similar content being viewed by others

References

T. Schultz et al., “Ecologically safe slag-forming mixture for continuous casting process,” Chern. Metally, No. 9, 32–39 (2008).

G. I. Aitel’, “Development and production of granulated pouring powder by dry spraying,” Chern. Metally, No. 6, 13–19 (1996).

I. Mertel’, “Automation of feeding granulated flux in the Voestalpine Stahl company,” Chern. Metally, No. 4, 44–46 (2008).

A. V. Kuklev and A. V. Leites, Continuous Casting Practice, Metallurgizdat, Moscow (2011).

Yu. M. Tsikarev et al., Patent 1459068 USSR, IPC C21C 5/54, “Slag-forming mixture for steel continuous casting, method for preparing slag-forming mixture and preparation of slag-forming granules,” subm. 08.13.1986, publ. 09.10.1996.

V. P. Nogtev et al., Patent 2100131 RF, IPC B22D11/00, “Method for preparing granulated slag-forming mixture,” subm. 11.21.1995, publ. 12.27.1997.

S. Z. Afonin et al., Patent 2271894 RF, IPC B22D11/00, “Method for preparing granulated slag-forming mixture,” subm. 06.24.2004, publ. 03.20.2006, Bull., No. 8.

S. N. Ushakov et al., Patent 2403124 RF, IPC B22D11/111, “Granulated slag-forming mixture for steel continuous casting,” subm. 12.07.2009, publ. 11.10.2010, Bull., No. 31.

S. Nose and N. Okuda, Patent KR810002023(B1) Korea, IPC B23K9/18, “Flux producing method for submerged are welding,” publ. 12.15.1981.

V. P. Nogtev, Patent 2330745 RF, IPC B22D11/00, “Method for preparing granulated slag-forming mixture,” subm. 07.18.2007, publ. 01.10.2008, Bull., No. 1.

V. P. Nogtev, Patent 2314177 RF, IPC B22D11/00, “Method for preparing granulated slag-forming mixture,” subm. 12.05.2006, publ. 08.10.2008, Bull., No. 22.

V. P. Nogtev, Patent 2345863 RF, IPC B22D11/00, “Method for preparing granulated slag-forming mixture,” subm. 05.21.2007, publ. 02.10.2009, Bull., No.4.

R. J. Philips and S. C. Diehl, Patent WO1996032216 (A1) GB, IPC B22D11/111, “Mould fluxes for use in the continuous casting of steel,” subm. 03.12.1996, publ. 10.17.1996.

R. J. Philips and S. C. Diehl, Patent US5577549 (A) USA, IPC B22D11/111, “Mould fluxes for use in the continuous casting of steel,” subm. 04.10.1995, publ. 11.26.1996.

R. J. Philips and S. C. Diehl, Patent US5538070 (A) USA, IPC B22D11/111, “Mould fluxes for use in the continuous casting of steel,” subm. 08.15.1994, publ. 07.23.1996.

N. Nobutaka et al., Patent JP2012179628 (A) Japan, IPC B22D11/108, “Hollow granular mold flux for continuously casting steel,” publ. 09.20.2012.

D. Wang, L. Yuan, et al., Patent CN102719621 (A) Chine, IPC C21C7/076, “Refining slag prepared from molten steel refining waste slag and method thereof,” subm. 03.29.2001, publ. 10.10.2012.

T. Nobuyuki et al., Patent JP5397318 (B2) Japan, IPC B22D11/108, “Mold flux for continuously casting steel,” publ. 12.08.2011.

H. J. Courtenay and R. J., Phillips, Patent KR900006927 (B1) Korea, IPC B22D11/108, “Fluxes for casting metals,” publ. 08.19.1985.

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Metallurg, No. 10, pp. 51–56, October, 2016.

Rights and permissions

About this article

Cite this article

Ryakhov, A.A., Kuklev, A.V., Anisimov, K.N. et al. Choice of Binder and Optimization of Slag-Forming Mixture Granulation Technology to Improve Granule Strength. Metallurgist 60, 1054–1061 (2017). https://doi.org/10.1007/s11015-017-0407-y

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11015-017-0407-y