Published experimental data about steel forging ingot chemical inhomogeneity with different steel weight and composition are summarized. An equation is obtained for calculating the carbon liquation factor over an ingot cross section in relation to weight and configuration (H/D ratio), and also on original carbon and sulfur content in cast steel.

Similar content being viewed by others

References

B. Sang, X. Kang, and D. Li, “A novel technique for reducing macrosegregation in heavy steel ingots,” J. Mater. Process. Techn., 210, 703–711 (2010).

K. Li, M. Wu, A. Ludwig, et al., “Modelling macrosegregation in a 2.45 ton steel ingot,” IOP Conf. Ser.: Mater. Sci. and Eng., 33 (2012).

“Report on the heterogeneity of steel ingots,” J. Iron Steel Inst., 103, 151 (1926).

H. Combeau, M. Zaloznik, S. Hans, et al., “Prediction of macrosegregation in steel ingots: infl uence of the motion and the morphology of equiaxed grains, “ Metall. Mater. Trans., 40B, 289–304 (2009).

I. N. Zigalo, K. S. Prosvirin, Ya. N. Malinochka, et al., Study of ingot structure formation by means of REM,” Stal, No. 8, 27–32 (1984).

D. Liu, X. Kang, B. Sang, et al., “Numerical study of macrosegregation formation of ingot cast in normal sand mold and water-cooled sand mold,” Acta Metall. Sin (Engl. Lett.), 24, No. 1, 34–64 (2011).

A. V. Kuksa, Cast Iron Steel-Pouring Molds, Metallurgiya, Moscow (1989).

B. G. Petukhov, “Effect of deoxidation versions on large ingot inhomogeneity,” Izv. Vyssh. Uchebn. Zaved., Chern. Met., No. 1, 35–38 (1969).

V. M. Senopal’nikov, G. A. Dubenets, and V. L. Sivkov, Control of Killed Steel Solidification Processes, NGTU, N. Novgorod (2009).

V. D. Solodovninov, Improvement of Smelting Technology and Degassing of Steel for Cold Rolling Rolls: Dissert. Cand. Techn. Sci., TsNIITMASh, Moscow (1988).

S. Onodera and Y. Arakida, “Effect of gravity on macrosegregation of larger steel ingots,” Indian Constr. News, No. 8, 358–368 (1959).

J. P. Gu and C. Beckermann, “Simulation of convection and macrosegregation in a large steel ingot,” Met. Mater. Trans., 30A, 1357–1366 (1999).

D. V. Rutskii, N. A. Zyuban, and S. B. Gamanyuk, “Effect of ingot chemical and physical inhomogeneity for a ton steel 38KhN3MFA ingot on pipe billet mechanical properties,” Izv. Samrsk. Nauch. Tsentra RAN, 12, No. 1(2) 489–492 (2010).

M. Wu, J. Li, A. Kharicha, et al., “Using a three-phase mixed columnar-equiaxed solidification model to study macrosegregation in ingot castings: perspectives and limitations,” Proc. 2013 Symp. on Liquid Metal Processing and Casting, pp. 171–180.

P. Machovcaka, A. Oplera, M. Tkadleckovab, et al., “The utilization of numerical modeling to optimize the production of heavy forging ingots in Vítkovice heavy machinery a.s.,” 1st Int. Conf. on Ingot Casting, Rolling and Forging, Brüssel-Saal, June 6, 2012, pp. 1–8.

M. Tkadleckova, P. Machovcak, K. Gryc, et al., “Setting a numerical simulation of filling and solidification of heavy steel ingots based on real casting conditions,” Mater. Technol., 46, 399–402 (2012).

K. Nishiguchi, K. Nakanishi, K. Nakayama, et al., “Prediction on macro segregation in large forging ingots,” 13th Int. Forgemasters Meeting, Pusan, Korea, Oct. 12–16, 2001, pp. 57–70.

Makichi Tateno, “Development of large size high quality steels and their future prospects as ‘Near net shape’ material,” Trans. ISIJ., 25, No. 2, 97–108 (1985).

Y. Ikeda, K. Morinaka, and T. Muraoka, “Recent technological progress on large ingots for rotor forgings,” 18th Int. Forgemasters Meeting, Pittsburgh, USA, Sept. 12–15, 2011, pp. 166–169.

A. P. Fomenko, Development and Study of Small Riser Ingot with Straight Conicity of Walls for Section Production: Auth. Abstr. Dissert. Cand. Tech. Sci., Bardin TsNIIchermet, Moscow (2007).

A. V. Mozgovoi, Optimization of Steel Pouring Parameters with Improved Axial Zone Properties for Large Section Rolling: Auth. Abstr. Dissert. Cand. Tech. Sci., Bardin TsNIIchermet, Moscow (2009).

A. M. Madyanov, “Control of steel solidifi cation in a mold during heavy forging ingot manufacture,” Proc. 2nd Meeting on Casting Process Theory, Metal Solidifi cation, Mashgiz, Moscow (1958), pp. 397–412.

V. A. Durynin and Yu. P. Solntsev, Study and Improvement of Production Technology with the Aim of Increasing Object Life of Large Forgings for Critical Purposes, KhimIzdat, St. Petersburg (2006).

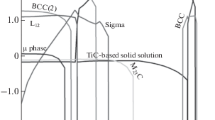

V. S. Dub, A. N. Romashkin, A. N. Mal’ginov, et al., “Effect of ingot geometry on its chemical inhomogeneity, Parts 1 and 2,” Metallurg, No. 10, 25–33, No. 12, 19–26 (2013).

V. S. Dub, A. N. Romashkin, A. N. Mal’ginov, et al., “Study of the effect of forging ingot confi guration on chemical element distribution over the cross section,” Probl. Chern. Met. Materialved., No. 1, 5–19 (2014).

B. Chalmers, Solidifi cation Theory [Russian translation], Metallurgiya, Moscow (1968).

Yasuto Ikeda, Koji Morinaka, and Tomohiro Muraoka, “Recent technological progress on large ingots for rotor forgings,” IFM, 166–169 (2011).

V. S. Dub, A. N. Romashkin, E. V. Makarycheva, et al., “Mehtod for developing production technology for forging ingots,” Tyazh. Mashinostr., No. 7, 13–20 (2012).

V. V. Nazaratin, A. N. Romashkin, I. A. Ivanov, and A. N. Mal’ginov, “Procedure for planning forging ingots without axial shrinkage defects,” Metallurg. Mashinostr., No. 3, 40–52 (2010).

T. I. Titova, D. V. Ratushev, S. A. Bocharov, et al., “Development and introduction of resource saving technology for producing large billets from a hollow ingot,” 14th MNTK, Problems of Materials Science with Planning Manufacture and Operation of NPP Equipment, St. Petersburg (2016).

Author information

Authors and Affiliations

Corresponding author

Additional information

* TsNIITMASh data.

Translated from Metallurg, No. 8, pp. 28–41, August, 2016.

Rights and permissions

About this article

Cite this article

Romashkin, A.N., Dub, V.S., Tolstykh, D.S. et al. Prediction of Carbon Liquation in Steel Forging Ingot Cross Section. Metallurgist 60, 786–801 (2016). https://doi.org/10.1007/s11015-016-0368-6

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11015-016-0368-6