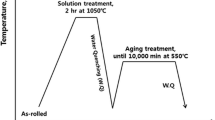

The microstructure and morphology of retained austenite are effective parameters in the mechanism of plasticity enhancement in quenching and partitioning steels. This study focused on the identification of morphological features of retained austenite through scanning electron microscopy, field emission-scanning electron microscopy, electron backscatter diffractometry, and transmission electron microscopy in a onestep quenched and partitioned C–Mn–Si steel. Retained austenite of different sizes and shapes (island-like and film-like) and martensite with lath-type morphology were observed at all partitioning times. Cementitecarbide (Fe3C) precipitates with a dominant spherical shape and average submicron size were also characterized in samples that had been partitioned for longer times.

Similar content being viewed by others

References

J. G. Speer, D. K. Matlock, B. C. De Cooman, and J. G. Schroth, “Carbon partitioning into austenite after martensite transformation,” Acta Mater., 51, 2611 (2003).

L. Wang and J. G. Speer, “Quenching and partitioning steel heat treatment,” Metallogr. Microstruct. Anal., 2, 268 (2013).

M. J. Santofimia, L. Zhao, and J. Sietsma, “Microstructural evolution of a low-carbon steel during application of quenching and partitioning heat treatments after partial austenitization,” Metall. Mater. Trans. A, 40, 46 (2009).

E. De Moor, S. Lacroix, L. Samek, et al., “Dilatometric study of the quench and partitioning process,” 3rd Int. Conf. on Advanced Structural Steels, Gyeongju, Korea (2006).

B. V. N. Rao and G. Thomas, “Structure-property relations and the design of Fe–4Cr–C base structural steels for high strength and toughness,” Metall. Trans. A, 11, 441 (1980).

X. D. Wang, B. X. Huang, Y. H. Rong, and L. Wang, “Mechanical and transformation behaviors of a C–Mn–Si–Al–Cr TRIP steel under stress,” J. Mater. Sci. Technol., 22, 625 (2006).

M. J. Santofimia, L. Zhao, R. Petrov, and J. Sietsma, “Characterization of the microstructure obtained by the quenching and partitioning process in a low-carbon steel,” Mater. Charact., 59, 1758 (2008).

M. J. Santofimia, L. Zhao, and J. Sietsma, “Microstructural evolution of a low-carbon steel during application of quenching and partitioning heat treatments after partial austenitization,” Metall. Mater. Trans. A, 40, 46 (2009).

M. J. Santofimia, L. Zhao, R. Petrov, and J. Sietsma, “Characterization of the microstructure obtained by the quenching and partitioning process in a low-carbon steel,” Mater. Charact., 59, 1758 (2008).

H. Y. Li, X. W. Lu, X. C. Wu, et al., “Bainitic transformation during the two-step quenching and partitioning process in a medium carbon steel containing silicon,” Mater. Sci. Eng. A, 527, 6255 (2010).

J. Mahieu, J. Maki, B. C. De Cooman, and S. Claessens, “Phase transformation and mechanical properties of Si-free CMnAl transformation-induced plasticity-aided steel,” Metall. Mater. Trans. A, 33, 2573 (2002).

H. R. Ghazvinloo and A. Honarbakhsh-Raouf, “Effect of partitioning time on microstructural evolution of C-Mn-Si steel in one-step quenching and partitioning process,” J. Mater. Environ. Sci., 6, 22 (2015).

X. D. Wang, Z. H. Guo, and Y. H. Rong, “Mechanism exploration of an ultrahigh strength steel by quenching–partitioning–tempering process,” Mater. Sci. Eng. A, 529, 35 (2011).

M. J. Santofimia, L. Zhao, and J. Sietsma, “Overview of mechanisms involved during the quenching and partitioning process in steels,” Metall. Mater. Trans. A, 42, 3620 (2011).

E. De Moor, S. Lacroix, A. J. Clarke, et al., “Effect of retained austenite stabilized via quench and partitioning on the strain hardening of martensitic steels,” Metall. Mater. Trans. A, 39, 2586 (2008).

H. R. Ghazvinloo, A. Honarbakhsh-Raouf, and A. R. Kiani Rashid, “Mechanical properties of a high Si and Mn steel heat treated by one-step quenching and partitioning,” Metallurgist, 59, 90 (2015).

E. Soppa, D. Willer, and D. Kuppler, “EBSD- and TEM-investigations of microstructure in the austenitic steel X6CrNiNb18-10 under cyclic loading,” 38th MPA-Seminar, Oct. 1–2, 2012, Stuttgart.

M. J. Santofimia, L. Zhao, R. Petrov, et al., “Microstructural development during the quenching and partitioning process in a newly designed low-carbon steel,” Acta Mater., 59, 6059 (2011).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Ghazvinloo, H.R., Honarbakhsh-Raouf, A. & Borhani, E. Morphological Characteristics of Retained Austenite in 0.362C–1.38Si–1.24Mn Steel Processed by One-Step Quenching and Partitioning. Metallurgist 60, 758–764 (2016). https://doi.org/10.1007/s11015-016-0363-y

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11015-016-0363-y