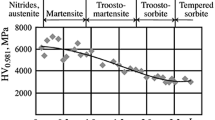

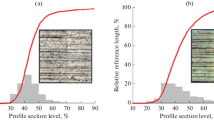

Comparative analysis is provided for features of structure and phase composition formation, hardness, roughness, and wear resistance of die steel 4Kh5MFS surface treated with a high-temperature pulsed plasma and laser radiation. It is established that after plasma treatment surface roughness Ra was 0.42–0.78 μm, and after laser treatment it was 1–1.17 μm. It is shown that after plasma treatment surface wear resistance is better than after laser treatment. Plasma treatment makes it possible to obtain surface hardness of the order of 840 HV that is 10% higher than after laser treatment. The data obtained indicate that pulsed sources of high-temperature plasma based on plasma accelerators may be considered as a promising tool for forming improved operating properties for a die steel 4Kh5MFS surface.

Similar content being viewed by others

References

V. L. Yakushin, “Surface hardening of carbon and low-alloy steels by a high-temperature pulsed plasma,” Tekhnol. Mashinostr., No. 5, 38–43 (2004).

B. A. Kalin, V. L. Yakushin, V. I. Pol’skii, et al., “Strengthening a surface and improving wear resistance of metallic materials with treatment by streams of high-temperature pulsed plasma,” Fiz. Khim. Obrab. Mater., No. 2, 21–27 (2010).

B. A. Kalin, V. L. Yakushin, P. S. Dzhumaev, et al., “Development of a method for creating metallic materials with a nanostructured surface layer by treatment with high-temperature pulsed plasma streams,” Fiz. Khim. Obrab. Mater., No. 1, 29–35 (2010).

N. S. Klimov, V. L. Podkovyrov, A. M. Zhiltukhin, et al., “Action of intense pulsed plasma streams on protected materials of thermonuclear reactor components within chambers,” Yad. Fiz. Inzh., 1, No. 3, 210–219 (2010).

M. A. Brutyan, V. P. Budaev, A. V. Volkov, et al., “Effect of fractal microstructure of a streamlined surface on turbulent boundary layer characteristics,” Uchen. Zap. TsAGI, 44, No. 4, 15–30 (2013).

A. V. Aborkin, V. E. Vaganov, A. N. Shlegel’, and I. M. Bukarev, “Effect of laser hardening on die steel microhardness and surface quality,” Metallurgist, 59, No. 7–8, 619–625 (2015).

V. Ya. Panchenko, I. N. Shiganov, A. I. Misyurov, et al., “Use of laser technology for improving the quality of die steel working surfaces,” Tekhnol. Mashinostr., No. 2, 18–22 (2003).

T. Dikova, “Surface modification of 3Ch2W8F and 4Ch5MFS steels by CO2 laser,” J. Techn. Univ. Plovdiv. Fund. Sci. Applic., 13, No. 7, 81–90 (2006).

Y. F. Ivanov, O. V. Krysina, Y. A. Kolubaeva, et al., “Modification of the structure and phase composition of structural steel by a microsecond e-beam,” High Temp. Mater. Proc.: Int. J., 17, No. 4, 221–226 (2013).

Yu. F. Ivanov, V. E. Gromov, D. A. Besonov, et al., “Fundamental properties and defect structure of steel 20Kh13 treated with an electron beam in a surface melting regime,” Fund. Probl. Sovr. Materialoved., 8, No. 3, 28–33 (2011).

A. V. Aborkin, V. V. Ryabkova, and D. V. Abramov, “Friction and wear of nitride and carbide coatings in contact with aluminum,” J. Friction and Wear, 34, No. 4, 294–301 (2013).

This research was carried out with partial financial support from the Russian Foundation for Basic Research within the scope of scientific project 14-08-97517 r_tsentr_a and a Presidential grant for young scientific candidates of science, MK-3040.2015.8.

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Metallurg, No. 7, pp. 88–92, July, 2016.

Rights and permissions

About this article

Cite this article

Aborkin, A.V., Vaganov, V.E., Klimov, N.S. et al. Treatment with a High-Temperature Pulsed Plasma and Laser Radiation for Die Steel Surface Layer Hardening. Metallurgist 60, 739–744 (2016). https://doi.org/10.1007/s11015-016-0360-1

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11015-016-0360-1