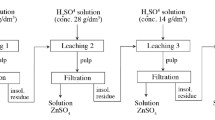

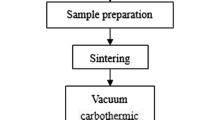

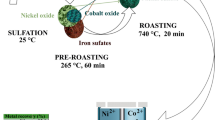

The object studied is Shaimerden oxidized zinc ore deposit containing zinc, lead, copper, iron, calcium, magnesium, aluminum, manganese and silicon. Chemical and mineralogical composition of the ore are investigated. It is established that ore coarse fraction contains more zinc carbonate and less zinc silicate compared with undersize particles. In addition, ore coarse fraction is richer in residual forms (nontronite, sphalerite) hardly soluble in sulphuric acid solution. Thermodynamic analysis of probable transformations during leaching is carried out, kinetics of coarse fraction and undersize particles of ore leaching is studied, and Pourbaix diagrams are plotted for analysis of processes occurring at a phase interface during leaching of oxidized zinc ore. Studies for stripping oxidized zinc ore are carried out on large (–20+1 mm) and small (–1+0 mm) fractions. Optimum leaching parameters are established for fine and coarse ore fractions: sulfuric acid concentration and process temperature and duration (C(H2SO4) = 150–160 g/liter, temperature 60°C, leaching time 60 min). Dependences are determined for the degree of zinc extraction into solution on sulphuric acid concentration, temperature, and leaching duration for coarse and fine ore factions.

Similar content being viewed by others

References

A. A. Abramov, Nonferrous Metal Oxidized Mixed Ore Enrichment Technology, Nedra, Moscow (1986).

L. A. Kazanbaev, P. A. Kozlov, and V. A. Kubasov, Zinc Pyrometallurgy. Leaching Processes, Ruda i Metally, Moscow (2007).

E. A. Glembotskii and E. A. Anfimova, Oxidized Nonferrous Metal Ore Flotation, Nedra, Moscow (1966).

V. D. Tyan, N. M. Mitryaeva, M. A. Sadenov, et al., “Zhairem zinc chemogenic carbonated ores,” Izv. AN RK, No. 4, 28–35 (1992).

E. E. Palenova, E. V. Belogub, and V. A. Kotlyarov, “Mineralogy of oxidized ores from Shaimerden deposit,” in: Contemporary Mineralogy: from Theory to Practice, 2010-1-85-0, RMS DPI (2010).

A. N. Gulyashinov, I. G. Antropova, Yu. O. Kalinin, and G. I. Khanturgaeva, Patent 2208059 RF, IPC7 C22B19/00, “Method for processing oxidized zinc ore,” subm. 11.20.2001, publ. 07.10.2003.

L. A. Kazanbaev, P. A. Kozlov, V. L. Kubasov, and A. V. Kolesnikov, Zinc Pyrometallurgy. Cleaning Electrolysis Solutions, Ruda i Metally, Moscow (2006).

Yu. V. Reshetnikov, P. A. Kozlov, A. V. Kolesnikov, and R. R. Asadulin, Patent 2375478 RF, IPC7 C22B19/00, “Zinc cinder processing method,” subm. 05.04.2008, publ. 12.10.2009.

E. V. Margulis, “x-Ray phase analysis of sulfide roasting products,” Coll. Work of VNIITsvetmet, Metallurgizdat, Moscow (1959), No. 5, pp. 165–166.

B. S. Khristoforov, “Behavior of moresnetite during determination of form of zinc compounds in ores,” ibid., pp. 156–157.

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Metallurg, No. 6, pp. 78–82, June, 2016.

Rights and permissions

About this article

Cite this article

Ramazanova, R.A., Seraya, N.V., Bykov, R.A. et al. Features of Shaimerden Deposit Oxidized Zinc Ore Leaching. Metallurgist 60, 629–634 (2016). https://doi.org/10.1007/s11015-016-0342-3

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11015-016-0342-3