Results are given for roll briquetting of metallurgical lime. Experimental results are obtained in laboratory presses and industrial briquetting units. Dependences are obtained for briquette density on compaction pressure and process productivity with different roll briquetting parameters. Technology and equipment presented in the work for lime briquetting make it possible to prepare high quality briquettes for the metallurgical industry. Results obtained are used in developing production briquetting processes and planning equipment.

Similar content being viewed by others

References

R. K. Agrawal and P. K. Pandey, “Productive recycling of basic oxygen furnace sludge in integrated steel plant,” J. Sci. Indust. Res., 64, 702–706 (2005).

V. V. Losev et al., Patent 2317341 RF, IPC C22B1/245, “Briquette for metallurgical production and method for its preparation,” Claim No. 2005137501/02, subm. 12.01.2005, publ. 02.20.2008, Byull., No. 21.

Yu. S, Krivchenko, et al., Patent 2333264 RF, IPC C22B1/00, “Line for preparing metallurgical charge material,” Claim No. 2006101190/02, subm. 01.13.2006, publ. 09.10.2008, Byull., No. 25.

Yu. N. Loginov et. al., Loose Material Roll Briquetting Mechanics, AMB, Ekaterinburg (2011).

Yu. N. Loginov, S. P. Burkin, and N. A. Babailov, “Effect of tool shape on boundary conditions and compaction during roll briquetting,” Stal, No. 9, 87–91 (2000).

Yu. N. Loginov, N. A. Babailov, and S. P. Burkin, “Volumetric deformation during roll briquetting of metallurgical production waste,” Metally, No. 1, 48–52 (2000).

Yu. N. Loginov, “Effect of a gas phase on briquetting process,” Stal, No. 8, 80–82 (2000).

Yu. N. Loginov, “Use of continuity conditions for analysis of gas-filled porous material deformation,” Izv. Vyssh. Uchebn. Zaved., Chern. Met., No. 11, 24–28 (2002).

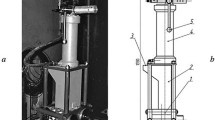

L. I. Polyanskii, M. V. Kobelev, and A. V. Vetoshkin, “Equipment for briquetting metallurgical lime screenings,” Novye Ogneup., No. 3, 99–100 (2014).

L. I. Polyanskii, M. V. Kobelev, and A. V. Vetoshkin, “Equipment for briquetting metallurgical lime screenings,” Chern. Metallurgiya: Byull. NTEiI, No. 7, 68–70 (2013).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Metallurg, No. 6, pp. 32–35, June, 2016.

Rights and permissions

About this article

Cite this article

Babailov, N.A., Polyanskii, L.I. & Loginov, Y.N. Briquetting Metallurgical Lime Screenings and Parameters Making it Possible to Improve Process Efficiency. Metallurgist 60, 576–580 (2016). https://doi.org/10.1007/s11015-016-0334-3

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11015-016-0334-3