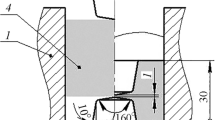

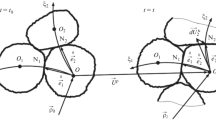

The combined rolling–extrusion of a porous aluminum billet is simulated mathematically using the finite-element method and QFORM V8 software. A three-dimensional problem statement with one plane of symmetry is used. The fields of displacement rates, stresses, temperatures, strains, and density are plotted. It is concluded that the distribution of these parameters is asymmetric about the processing axis. It is revealed that the density achieved in the process is close to that of the compact material.

Similar content being viewed by others

References

Peng Yuelin, Hu Jian, and Mo Bin, “Analysis of stress and temperature in the CONFORM forming process–Foundation theory,” J. Centr. South Univ. Technol., 3, No. 2, 153–158 (1996).

S. P. Burkin and Yu. N. Loginov, “Continuous extrusion of billets through a two-part container,” Steel in Transl., 27, No. 10, 46–52 (1997).

S. P. Burkin, Yu. N. Loginov, and E. A. Korshunov, Patent No. 2038913 RF, IPC B22D11/12, “A method and equipment for combined continuous casting and forming of metals,” subm. 09.22.1992, publ. 07.09.1995.

S. P. Burkin, Yu. N. Loginov, and E. A. Korshunov, Patent No. 2016682 RF, IPC B22D11/20, “A method and equipment for combined continuous casting and forming of metals,” subm. 10.13.1992, publ. 07.30.1994.

V. M. Sergeev, Yu. N. Loginov, Yu. V. Gorokhov, and N. N. Zagirov, “Optimizing the billet dimensions for continuous extrusion,” Metally, No. 1, 98 (1993).

S. B. Sidel’nikov, N. N. Dovzhenko, and N. N. Zagirov, Combined and Complex Methods for Processing Nonferrous Metals and Alloys, MAKS Press, Moscow (2005).

Yu. N. Loginov and S. P. Burkin, “Energy saving in extrusion processes,” Tsvet. Metally, No. 10, 81–87 (2002).

N. N. Zagirov, S. B. Sidel’nikov, E. V. Ivanov, and V. M. Bespalov, “Production of a fi brous wire from AD31 alloy shavings by combined rolling–extrusion,” Obrab. Sploshn. Sloist. Mater., No. 38, 10–15 (2012).

S. B. Sidel’nikov, A. I. Grishechkin, and N. N. Dovzhenko, “Design and assimilation of a pilot mill for combined rolling–extrusion,” Tekhnol. Legk. Splavov, No. 5–6, 41–44 (2002).

N. N. Dovzhenko, I. N. Dovzhenko, and S. B. Sidel’nikov, “Energy and force parameters of the combined rolling–extrusion process,” Vest. MGTU im. Nosova, No. 4, 54–61 (2006).

N. N. Zagirov and Yu. N. Loginov, Technological Foundations of the Production of Materials and Products from Loose Swarf of Copper and Its Alloys by Forming Methods, SFU, Krasnoyarsk (2015).

Yu. N. Loginov and O. F. Degtyarev, “Effect of the strain rate on the structural hardening of extruded 6061 aluminum-alloy tubes,” Tekhnol. Legk. Splavov, No. 4, 123–127 (2007).

E. V. Ivanov, I. N. Gigel’, Ya. V. Kovaleva, and N. N. Zagirov, “Comparison of the properties of bars and wires produced by discrete extrusion and combined rolling–extrusion of silumin swarf,” in: Proc. 16th Int. Sci.-Tekh. Ural Schk.–Sem. of Young Metallurgists, UrFU, Ekaterinburg (2015), Vol. 1, pp. 70–72.

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Metallurg, No. 6, pp. 14–17, June, 2016.

Rights and permissions

About this article

Cite this article

Ershov, A.A., Loginov, Y.N., Zagirov, N.N. et al. Simulation of the Consolidation of a Porous Material in a Combined Rolling–Extrusion Process. Metallurgist 60, 561–565 (2016). https://doi.org/10.1007/s11015-016-0331-6

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11015-016-0331-6