Results are given for processing magnesium-containing slurry formed in the stage of thorough dehydration of molten carnallite during magnesium metal production. A resource saving technology and a production line are developed for processing magnesium production slurry into magnesia cement.

Similar content being viewed by others

References

V. D. Yazev, Yu. P. Kudryaskii, G. N. Svalov, et al., Inventor’s Cert. 1114670 USSR, IPC6 С05D5/00, “Method for treating magnesium production saline waste,” subm. 10.15.1982, publ. 09.23.1984.

Yu. P. Kudryavskii, V. P. Kazantsev, and Yu. F. Trapeznikov, Application for Useful Model 25505 RF, IPC7 С05F03/06, “Device for preparing organomineral fertilizers,” subm. 03.26.2002, publ. 10.10.2002.

A. V. Popov and S. S. Baeva, “Effect of magnesium fertilizers on grain lodging resistance,” Zern. Khozyaistvo, No. 10, 32–33 (1982).

K. F. Paus, Drilling Solutions, Nedra, Moscow (1978).

I. A. Barannik, V. V. Radchenko, and Yu. I. Rys’eva, “Study of magnesium production hygroscopic waste,” Tsvet. Met., No. 6, 27–30 (1982).

L. I. Orlova and A. I. Desyatnichko, Patent 2151156 RF, IPC7 С08L97/02, “Composite formulations for producing a structural pressed beam,” subm. 03.10.1999, publ. 06.20.2000.

Yu. F. Trapeznikov, Yu. P. Kudryavskii, and N. A. Shundikov, Patent 2172331 RF, IPC7 С09K3/15, “Method for preparing and anti-icing preparation,” subm. 03.31.2000, publ. 08.20.2001.

V. V. Teterin, R. G. Freidlina, V. A. Besedin, et al., Patent 2155240 RF, IPC7 С22В7/00, “Method for processing magnesium production waste,” subm. 07.28.1997, publ. 08.27.2000.

I. N. Lipunov, A. S. Teploukhov, M. S. Kovel’, et al., “Study of composition and properties of magnesium metallurgical slurries,” ZhPKh, 77, No. 2, 206–209 (2004).

A. V. Bolzhenskii, V. S. Burov, and V. S. Kolokol’nikov, Mineral Cement Substances, Stroizdat, Moscow (1973).

I. N. Lipunov, P. S. Vlasov, L. V. Vasilenko, et al., “Ecological, economic, and social aspects of waste wood utilization from Sverdlovsk region wood enterprises,” in: Ecological Problems and Chemical Technologies, UGLTA, Ekaterinburg (2000), pp. 142–151.

V. I. Zyryanova, M. A. Savinkina, and A. T. Logvinenko, “Effect of impurities on magnesium cement hardened structure and properties,” Sib. Khim. Zh., No. 3, 116–119 (1992).

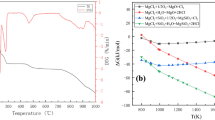

I. N. Lipunov, A. S. Teploukhov, and D. A. Storchak, “Thermogravimetric study of magnesium oxide hydration,” in: Scientific Works, Ekaterinburg (2004), Iss. 3, pp. 136–140.

V. V. Boldyrev, Methods for Studying Solid Substance Thermal Decomposition Kinetics, Metallurgizdat, Moscow (1959).

I. N. Lipunov, M. S. Kovel’, A. S. Teploukhov, et al., “Kinetics and thermodynamic of hardening processes within systems MgO–H2O and MgO–MgCl2–H2O,” Zh. Prikl. Khim., 77, No. 4, 548–552 (2004).

I. N. Lipunov, N. A. Belkin, V. I. Alikin, et al., Application 17300 for Useful Model, IPC7 В28D1/28, “Production line for processing magnesium production carnallite slurry,” publ. 03.27.2001, Byull., No. 9.

I. N. Lipunov, V. V. Kurnosenko, V. A. Besedin, et al., Patent 2185349 RF, IPC7 С04В28/30, “Raw material mix for preparing building objects,” subm. 03.22.2000, publ. 07.20.2002.

I. N. Lipunov, A. A. Yupatov, V. I. Alikin, et al., Patent 2199503 RF, IPC7 С04В28/30, “Composite mix formulation for preparing building wood-composite materials,” subm. 03.22.2001, publ. 02.23.2003.

I. N. Lipunov, V. V. Tetyukhin, V. A. Besedin, et al., Patent 2163541 RF, IPC7 В27N3/02, “Method and composition for preparing heat and sound insulation wood-composite materials,” subm. 04.04.2000. publ. 02.27. 2001.

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Metallurg, No. 3, pp. 20–26, March, 2015.

Rights and permissions

About this article

Cite this article

Lipunov, I.N., Pervova, I.G. & Nikiforov, A.F. Comprehensive Conversion of Magnesium-Containing Slurry into Readily Saleable Materials. Part 1. Utilization of Magnesium Production Slurry in Magnesia Cement Material. Metallurgist 59, 193–200 (2015). https://doi.org/10.1007/s11015-015-0083-8

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11015-015-0083-8