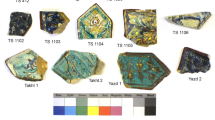

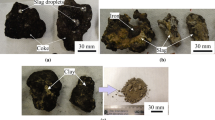

Scanning electron microscopy is used to study fluxes used in ESSW-6 of the Chelyabinsk Metallurgical Combine for producing refining slag in a steel-pouring ladle during extra-furnace treatment of steel by AKOS (complex steel processing facility). Three forms of flux containing feldspar are studied: fluorite briquettes FB 85 (TU 48-15-29–91) and fluorite concentrates FK 85 and FK 92 (GOST 29220–91). The average specimen chemical composition and its individual fragments are studied. It is established that for extra-furnace treatment of low-carbon stainless steel it is most preferable to use fluorite concentrate F 92 with a high basic element concentration and low (less than 3%) carbon content.

Similar content being viewed by others

References

D. Ya. Povolotskii and Yu. A. Gudin, Stainless Steel Production, YRGU, Chelyabinsk (1998).

A. A. Babakov and M. V. Pridantsev, Corrosion-Resistant Steels, Metallurgiya, Moscow (1971).

This research was carried out within the scope of the Federal Targeted Program on Research and Development for Priority Development Areas in the Scientific and Technological Complex of Russia in 2014–2020 (Contract No. 14.574.21.0054).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Metallurg, No. 10, pp. 48–50, October, 2014.

Rights and permissions

About this article

Cite this article

Tokovoi, O.K. Study of Fluorite-Containing Fluxes by Scanning Electron Microscopy. Metallurgist 58, 880–882 (2015). https://doi.org/10.1007/s11015-015-0011-y

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11015-015-0011-y