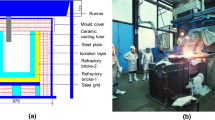

Results are presented for thermal imaging monitoring of a series of cold simulation experiments of solidification for six models of steel ingots weighing 235 tons on a scale of 1:25. Nine model ingots are studied. Ingot parameter H/D in models is varied within limits from 1 to 2 and taper from 2 to 18 with steps of 0.5 and 8 respectively. Detailed description of the experimental procedure is provided in parts I and II. An FLIR SC640 thermal imager is used for temperature measurement.

Similar content being viewed by others

Reference

A. N. Romashkin, A. N. Mal’ginov, and D. S. Tolstykh, “Effect of ingot geometry on volume of axial porosity within it,” Electrometallurgiya, No. 7, 36–39 (2013).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Metallurg, No. 4, pp. 47–50, April, 2014.

* For Parts I and II see Metallurgist, No. 2, 119–124 and No. 3, 179–183 (2014).

Rights and permissions

About this article

Cite this article

Romashkin, A.N., Tolstykh, D.S., Mal’ginov, A.N. et al. Study of the Effect of Ingot Geometry on its Solidification Features Based on Cold Simulation. Part III* . Metallurgist 58, 264–268 (2014). https://doi.org/10.1007/s11015-014-9899-x

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11015-014-9899-x