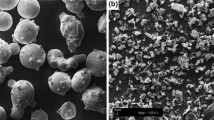

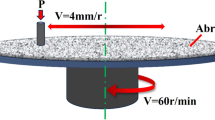

The effect of crystallization conditions (during casting in a copper chill mold, cast iron mold, and with ingot preparation by high-gradient directional crystallization) of high-strength deformable wear- and corrosionresistant alloy based on nickel-copper grade VKM1 (NMKZhMts-30-4-2-1-VI) on grain size in final semifinished product is studied, i.e., extruded bar with an identical heat treatment regime. It is shown that ingot casting in a cast iron mold provides preparation of a dense original ingot with coarse eutectic fragment precipitates that do not dissolve entirely on heating for extrusion, they initiate development of a considerable amount of slip planes during extrusion, and on quenching delay grain growth. This provides formation of a more fine-grained structure compared with metal cast in a copper chill mold and that obtained by high-gradient directional crystallization.

Similar content being viewed by others

References

L. E. Shoemaker and G. P. Smith, “A century of monel metal: 1906–2006,” JOM, 58, Sept., 22–26 (2006).

L. A. Chatynyan, “New wear-resistant high-temperature alloys for friction assemblies,” in: Friction and Wear Theory and Standardization Problems [in Russian], Priok. Knizh. Izd., Bryansk (1978), pp. 314–325.

L. A. Chatynyan, N. F. Lashko, et al., “Effect of silicon on wear resistance of nickel superalloys of the VZhL-2 type with friction under high-temperature conditions,” Mashinovedenie, No. 4, 32–39 (1976).

M. K. Vovk, A. N. Gorbunov, and O. E. Kestner, “Siliceous copper-nickel alloy for slide valve pairs of precision heating equipment,” in: Materials for Friction Components [in Russian], Moscow (1966), pp. 10–20.

V. I. Lukin, A. G. Evgenov, G. I. Morozova, and V. A. Kalitsev, “New deformable alloy of the system Ni–Cu–Si–Fe–Mn (siliceous monel),” Tekhnol. Mash., No. 6, 5–7 (2006).

A. G. Evgenov, G. I. Morozova, and V. I. Lukin, “Features of phase transformation in alloys of the system Ni–Cu–Si–Fe–Mn,” MiTOM, No. 8, 36–39 (2006).

E. V. Razuvaev, “Production of semi-finished products of contemporary and perspective high-temperature alloys,” in: Manufacturing Technology for Aviation Materials [in Russian], VIAM (2002), pp. 35–39.

E. N. Kablov, O. G. Ospennikova, and B. S. Lomberg, “Combined innovation technology for isothermal stamping in air in a regime of superplastic disks of superalloys,” in: Aviation Materials and Technology. Jubilee Sci.-Tech. Coll. (appendix to journal Aviation Materials and Technology) [in Russian], VIAM, Moscow (2012), pp. 129–141.

B. S. Lomberg, S. V. Ovsepyan, M. M. Bakradze, and I. S. Mazalov, “High-temperature nickel superalloys for gas turbine engine components,” ibid., pp. 52–57.

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Metallurg, No. 8, pp. 77–81, August, 2013.

Rights and permissions

About this article

Cite this article

Evgenov, A.G., Kalitsev, V.A. & Rogalev, A.M. Effect of Siliceous Monel VKM1 Crystallization Conditions on Extruded Semi-Finished Product Structure. Metallurgist 57, 736–741 (2013). https://doi.org/10.1007/s11015-013-9794-x

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11015-013-9794-x