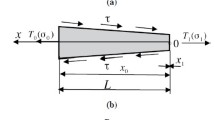

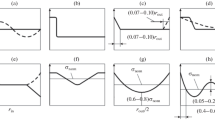

Relations are presented to determine the rolling pressure and forward tension on strip during its asymmetric cold rolling. The relations account for the reduction and strain-hardening of the strip, unit frictional forces, the difference between the peripheral velocities of the work rolls, and the tension on the ends of the strip. Lowering the pressure of the strip metal on the rolls helps save energy, increases mill productivity, improves the quality of the rolled product, and reduces the metal content of the equipment.

Similar content being viewed by others

References

E. A. Maksimov, R. L. Shatalov, and N. Sh. Boskhamdzhiev, Production of Flat Strip by Rolling [in Russian], Teplotekhnik, Moscow (2008).

V. N. Vydrin, A. S. Fedosenko, and V. I. Krainov, Continuous Rolling [in Russian], Metallurgiya, Moscow (1980).

L. A. Agishev, A. I. Grishkov, A. R. Fisher, et al., “Making the cold-rolling of corrosion-resistant steel more efficient by maintaining a difference between the peripheral velocities of the rolls,” Metallurg, No. 4, 32–34 (1983).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Metallurg, No. 11, pp. 54–56, November, 2010.

Rights and permissions

About this article

Cite this article

Maksimov, E.A. Reducing pressure on the rolls and tension in the asymmetric cold-rolling of strip. Metallurgist 54, 753–757 (2011). https://doi.org/10.1007/s11015-011-9370-1

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11015-011-9370-1