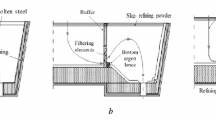

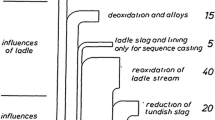

An integrated technology has been developed for obtaining continuous-cast slabs to be used in rolling plates for critical applications. Special filtration elements are installed in partitions inside the tundish to reduce the content of nonmetallic inclusions in the continuous-cast semifinished product. A channeled ceramic lance for injecting the steel with argon has been developed and installed in the bottom of tundishes to remove nonmetallic inclusions 20 μm or smaller. Metallographic studies confirm the effectiveness of the new technology for obtaining plates of high-strength steels.

Similar content being viewed by others

References

O. B. Isaev, O. V. Nosochenko, L. S. Lepikhov, et al., “The tundish – a key functional element for obtaining high-quality metal products,” Stal, No. 7, 20–23 (2001).

L. S. Lepikhov, S. G. Melnik, O. B. Isaev, et al., “Development and introduction of an integrated technology for removing nonmetallic inclusions from a steel melt in the tundish of a continuous caster,” in: Heat and Mass Transfer Processes in Metallurgical Systems, Mariupol (2000), pp. 232–234.

E. P. Diyuk, V. V. Kislitsya, O. B. Isaev, et al., Ukrainian Patent No. 26193, MPK C22B 9/00, Method for the Continuous Refining of Steel in Tundishes, Publ. 09.10.2007, Byull., No. 1.

L. S. Lepikhov, S. G. Melnik, O. B. Isaev, et al., “Technology for obtaining continuous-cast semifinished products for skelp that meets stringent requirements in ultrasonic tests,” in: Proc. Int. Sci.-Techn. Conf. “Progressive Plate Steels for Large-Diameter Oil- and Gas-Line Pipe and Crucial Metal Structures,” Metallurgizdat, Moscow (2004), pp. 13–15.

O. B. Isaev, O. V. Nosochenko, L. S. Lepikhov, et al., “Improving the design of tundishes for obtaining high-quality steel,” Metall. Gornorud. Promyshl., No. 7, 202–206 (2002).

O. B. Isaev, L. S. Lepikhov, O. V. Nosochenko, et al, “Integrated technology for refining skelp steel in tundishes to obtain rolled products satisfying foreign standards,” in: Proc. Sci.-Techn. Conf. “Current Status of Continuous Steel Casting at Ukrainian Metallurgical Plants and the Main Approaches to Improving this Technology,” Kharkov (2001), pp. 82–84.

E. P. Diyuk,V. V. Kislitsya, O. B. Isaev, et al., Ukrainian Patent No. 32074, MPK B22D 11/00, Lance-Equipped Unit for Injecting Gases into Molten Metal, Publ. 05.12.2008, Byull., No. 9.

E. P. Diyuk, V. V. Kislitsya, O. B. Isaev, et al., Ukrainian Patent No. 26194, MPK B22D 11/00, Method of Damping Eddies Formed in Metal Melts Above a Nozzle, Publ. 09.10.2007, Byull., No. 14.

O. Nosochenko, L. Lepikhov, O. Isayev, et al., “Complex technological process for tundish refining of line pipe steel used for manufacture of plates with higher ultrasonic requirements,” 4th Eur. Continuous Casting Conf. Proc., Birmingham (2002), pp. 69–75.

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Metallurg, No. 11, pp. 42–46, November, 2009.

Rights and permissions

About this article

Cite this article

Isaev, O.B. Improving the technology for the tundish refining of steel in order to elevate the quality of continuous-cast semifinished products and rolled plates. Metallurgist 53, 672–678 (2009). https://doi.org/10.1007/s11015-010-9231-3

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11015-010-9231-3