More than half the thermal potential of the initial slab on a hot-strip mill is left in the finished coil of hotrolled strip, and extracting this energy as quickly as possible is an important goal in the casting technology. The controlled cooling of coiled strip of any grade of steel – including cooling during the stages of thermostatting and accelerated cooling – makes the hot-rolling operation more efficient and allows the heat stored in the coil to be used to complete structural transformations in the metal on certain sections of the strip. The thermal potential of the coil can also be used for other purposes, such as for conversion into industrial heat carriers like steam. Examples are given to illustrate the use of this energy-saving technology. The controlled cooling of coils makes it possible to increase the output of coiled strip without having to store hot coils or perform various additional heat treatments.

Similar content being viewed by others

References

E. A. Nitskevich and V. I. Umanskii, “The use of secondary energy resources in ferrous metallurgy abroad,” Obzor. Inform. Ser. “Obshchie Otraslevye Voprosy,” No. 3 (1985).

V. V. Chashchin, “Analysis of the change in the heat content of metal during its hot rolling on wide-strip mills,” Chern. Metall.: Byull. NTiEI, No. 7/8, 58–59 (2000).

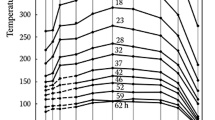

V. V. Chashchin, V. A. Kapitanov, and E. S. Popov, “Use of a temperature-based mathematical model to develop a technology for the controlled cooling of coiled hot-rolled strip,” Proizvod. Prokata, No. 8, 17–23 (2008).

V. V. Chashchin, “Conceptual foundation of technologies for the controlled cooling of coils in a casting-rolling complex,” ibid., No. 12, 13–15 (2005).

V. V. Chashchin, S. S. Toropov, E. S. Popov, et al., Russian Federation Patent No. 2345858, MPK B21B45/02, Method of Thermally Insulating the Outer Surfaces of Coils of Hot-Rolled Strip and Equipment for Its Implementation, publ. 02.10.2009, Byull. No. 4.

A. M. Snitkin, Effectiveness of the Use of Secondary Energy Resources in Ferrous Metallurgy: Engineering Sciences Candidate Dissertation, MISiS, Moscow (1980).

V. V. Chashchin, Russian Federation Patent No. 1584384, MPK C21D1/02, Method of Cooling Coils of Hot-Rolled Steel Strip and Equipment for Its Implementation, publ. 02.07.1992, Byull. No. 29.

V. V. Chaschin, Device for Cooling Coils of Hot-Rolled Strip,WO 93/10270, Application No. PCT/SU91/00238, IPC C21D1/6s, Gazette of Int. Pat. Applic., No. 13, Int. Publ. Date May 27, 1993, p. 6644.

N. B. Skorokhvatov, A. F. Savinykh,V. V. Chashchin, et al., Russian Federation Patent No. 2286859, MPK B21C47/00, Method of Cooling Hot-Rolled Strip in Coils During Transport and Equipment for Its Implementation, publ. 11.10.2006, Byul. No. 31.

V. V. Chashchin, Device for Cooling Coils of Hot-Rolled Strip, WO 93/10268, Application No. PCT/SU91/00233, IPC C21D1/6s, Gazette of Int. Pat. Applic., No. 13, Int. Publ. Date May 27, 1993, p. 6642.

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Metallurg, No. 8, pp. 65–69, August, 2009.

Rights and permissions

About this article

Cite this article

Chashchin, V.V. Controlled cooling of coils – an important factor in energy conservation for the hot-rolling of strip. Metallurgist 53, 506 (2009). https://doi.org/10.1007/s11015-009-9189-1

Received:

Published:

DOI: https://doi.org/10.1007/s11015-009-9189-1