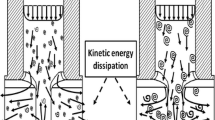

Results are presented from an analysis of flows of a melt for two widely used types of pouring nozzles designed especially for the continuous casting of thin steel slabs. The theoretical predictions that are obtained are reliable because the computations were performed using an advanced method of calculating turbulent flows that is based on the K–ε model and the universal numerical method of finite elements. It is shown that the use of a closed-bottom nozzle ensures that the melt will flow rapidly over the covering slag at the meniscus, which makes it possible to remove nonmetallic inclusions from the steel. At the same time, the high rate of flow of the melt along the solid skin of the semifinished product can result in excessive deformation of the skin by the jet of superheated alloy. The jet penetrates deep into the body of the semifinished product when a direct-flow nozzle is used. This prevents almost any of the nonmetallic inclusions from ascending to the meniscus and the covering slag, which would allow further refining of the steel. On the other hand, the low rate of flow of the melt along the skin near the narrow faces of the slab makes it less likely that the skin will be deformed or have its growth impeded.

Similar content being viewed by others

References

Kh. Shtroibel, “Continuous casting of thin slabs with compression of the liquid core: concepts and study results,” Chern. Metall., No. 12, 37–40 (1999).

D. Ameling, Kh. Khartog, and R. Shteffen, “Combining the continuous casting of thin slabs with hot rolling in the nations of the EC,” ibid., No. 5, 55–69 (2002).

K. Oler, Kh. Odental, G. Pfaifer, and I. Lemanovich, “Numerical modeling of the flow and solidification of metal in a continuous caster designed for casting thin slabs,” ibid., No. 8, 22–28 (2002).

V. I. Il’in, L. K. Fedorov, B. A. Korotkov, et al., “Control of flows of steel in the mold of a continuous caster with the use of pouring nozzles,” Izv. Vyssh. Uchebn. Zaved. Chern. Metall., No. 9, 19–22 (2002).

V. N. Gushchin, A. V. Kuklev, and V. M. Parshin, “Hydro-stabilization methods for delivering a melt to the slab molds of a continuous caster,” Stal, No. 7, 16–19 (2007).

S. B. Eroshin, G. S. Bobylev, V. N. Popovich, et al., “Experience with the use of submersible nozzles made by the company Foseko GmbH for the continuous slab caster at the Severstal metallurgical combine,” ibid., No. 5, 61–63 (2007).

B. G. Thomas, I. J. Mika, and F. M. Najjar, “Simulation of flow inside a continuous slab-casting,” Metall. Trans., Ser. B, 21B, 387–400 (1990).

X. Huang, B. G. Thomas, and F. M. Najjar, “Modeling superheat removal during continuous casting of steel slabs,” ibid., 23B, 339–356.

A. N. Cherepanov, V. N. Popov, V. P. Komshukov, and D. V. Foigt, “Numerical analysis of the structure of the flows in the solidifying molten part of a steel ingot undergoing continuous casting,” Izv. Vyssh. Uchebn. Zaved. Chern. Metall., No. 10, 41–45 (2007).

B. E. Launder and D. B. Spaulding, “The numerical computation of turbulent flows,” Comp. Mech. Appl. Mech. Eng., 3, No. 2, 269–289 (1974).

V. V. Belousov, F. V. Nedopekin, and I. L. Povkh, “Heat and mass transfer in a solidifying binary melt under mixedconvection conditions with allowance for turbulence,” Inz. Fiz. Zh., 67, No. 3/4, 202–208 (1994).

L. G. Loitsyanskii, Mechanics of Liquids and Gases [in Russian], Nauka, Moscow (1970).

V. T. Borisov, Theory of the Two-Phase Zone of Metal Ingots [in Russian], Metallurgiya, Moscow (1987).

Yu. A. Samoilovich (ed.), Thermal Processes in the Continuous Casting of Steel [in Russian], Metallurgiya, Moscow (1982).

V. S. Rutes,V. I. Askol’dov, D. P. Evteev, et al., Theory of Continuous Casting. Technological Foundations [in Russian], Metallurgiya, Moscow (1971).

A. V. Leites, The Protection of Steel During Continuous Casting, Metallurgiya, Moscow (1984).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Metallug, No. 6, pp. 51–56, June, 2009.

Rights and permissions

About this article

Cite this article

Samoilovich, Y.A. Effect of the configuration of the pouring nozzle on the flow of the melt in a thin slab undergoing solidification. Metallurgist 53, 348 (2009). https://doi.org/10.1007/s11015-009-9185-5

Received:

Published:

DOI: https://doi.org/10.1007/s11015-009-9185-5