Abstract

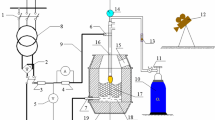

The tapping operation is very important in the use of oxygen converters to obtain semifinished products, since this is the point at which the ultimate chemical composition of the steel is formed, the metal undergoes deoxidation, and slag is formed for use in subsequent out-of-furnace treatments. This article studies the process of the mixing of the metal in the ladle during the tapping of 240-ton heats of carbon and low-alloy steels from converters at EKO Stahl (in Germany). To obtain the maximum effect during tapping, the total amount of power supplied for mixing of the metal in the ladle by the falling stream and the injected gas must be kept at a continuously high level. One way of achieving this is increasing the amount of gas injected during the second period of the tapping operation.

Similar content being viewed by others

References

A. A. Svyazhin, E. Krushke, and A. G. Svyazhin, Metallurg, No. 11, 43–45 (2004).

V. V. Pichugin, E. Kh. Shakhpazov, and A. G. Svyazhin, Ivz. Vyssh. Uchebn. Zaved. Chern. Metall., No. 2, 19–21 (1990).

A. G. Svyazhin, Theory and Practice in Improving the Quality of Steel [in Russian], Metallurgiya, Moscow (1985), pp. 26–40.

Author information

Authors and Affiliations

Additional information

__________

Translated from Metallurg, No. 4, pp. 42–44, November, 2005.

Rights and permissions

About this article

Cite this article

Svyazhin, A.A., Krushke, E. Mixing of the metal and mass transfer during the tapping of a semifinished product from an oxygen converter. Metallurgist 49, 432–438 (2005). https://doi.org/10.1007/s11015-006-0019-4

Issue Date:

DOI: https://doi.org/10.1007/s11015-006-0019-4