Abstract

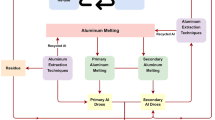

A comparison is made of the characteristics of dross formed on lines that make rolled products with anti-corrosion coatings. Two methods of recycling dross to rid it of harmful impurities are examined. In distillation sublimation, an increase in temperature to 1280°C helps maximize the amount of zinc that is transferred from the dross to the storage container. In this case, 70–85% of the zinc is recovered from the dross. The resulting melt contains 99.5% zinc, 0.03% iron, and 0.04% aluminum. Up to 70% of the metallic zinc in dross is recovered when the dross is dissolved in an aluminum melt containing 10–25% aluminum. The use of ammonium chloride increases the amount of iron removed from the secondary zinc and shortens the recycling operation.

Similar content being viewed by others

REFERENCES

I. I. Teindl, New Methods of Applying Metallic Coatings [in Russian], Metallurgizdat, Moscow (1963).

R. M. Cherkasskii, A. V. Maksimova, et al., “Recovering zinc from galvanizing wastes,” Stal', No. 2, 89 (1993).

A. V. Vitkin and I. I. Teindl, Metallugical Coatings for Steel Sheet and Strip [in Russian], Metallurgiya, Moscow (1971).

Tekhnologiya BIEK: Inform. Bull.

Author information

Authors and Affiliations

Additional information

Yu. A. Kabanov, V. V. Pol'shikov, V. D. Petrov, and R. A. Mukaev also participated in this study.

__________

Translated from Metallurg, No. 7, pp. 60–61, July, 2005.