Abstract

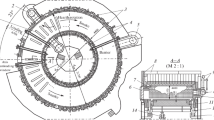

A new complex being built at the Nizhniy Tagil Metallurgical Combine will include the following furnaces: a rotary heating furnace with a capacity of 50 tons/h or 100 semifinished products/h; another rotary furnace, equipped with quenching tables, for heating wheels prior to quenching; a tempering furnace. All of the furnaces will have modern control systems to control the processes of heating the semifinished products and heat-treating the wheels. These advanced furnaces will make it possible to improve the quality of the heating operation, reduce the energy costs incurred in production, and decrease the amount of metal lost due to oxidation.

Similar content being viewed by others

Author information

Authors and Affiliations

Additional information

__________

Translated from Metallurg, No. 5, p. 62, May, 2005.

Rights and permissions

About this article

Cite this article

Krokhin, B.V. Furnaces for Rolling Mills at the Nizhniy Tagil Metallurgical Combine. Metallurgist 49, 200–201 (2005). https://doi.org/10.1007/s11015-005-0078-y

Issue Date:

DOI: https://doi.org/10.1007/s11015-005-0078-y