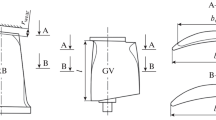

Using the energy approach formulated earlier by the authors, a mathematical model was constructed, which in turn is the basis of the calculation method for predicting the residual life time of the rectification column for production of ethylene under the wind load and atmospheric corrosion. It should be noted that wind load is shunting in nature with constant pressure on the column and frequent gusts. There is an external surface corrosion-mechanical crack in the circular weld, by which the column is attached to the base. The corrosive environment penetrates into this crack. Such a corrosive environment together with the shunting wind load intensifies crack propagation to the size, which causes failure of the column. Using the energy approach, this problem is reduced to special differential equations with special delta functions, which are solved approximately for a large number of wind gusts. Using the energy approach the dependence of the 09G2C steel column residual life time on the number of wind gusts, was investigated.

Similar content being viewed by others

References

V. I. Pokhmurskyi, Corrosion Fatigue of Metals [in Russian], Metallurgiya, Moscow (1985).

O. N. Romaniv, S. Ya. Yarema, G. N. Nykyforchyn, N. A. Makhutov, and M. M. Stadnyk, Fatigue and Cyclic Crack Resistance of Structural Materials [in Russian], Naukova Dumka, Kyiv (1990).

G. P. Cherepanov, Mechanics of Brittle Fracture [in Russian], Nauka, Moscow (1974).

V. V. Panasyuk and I. M. Dmytrakh, Influence of Corrosive Environments on Local Fracture of Metals Near Stress Concentrators [in Ukrainian], Karpenko Physico-Mechanical Inst., Lviv (1999).

V. V. Panasyuk, A. Ye. Andreikiv, and V. Z. Parton, Basis of Fracture Mechanics [in Russian], Naukova Dumka, Kyiv (1988).

Handbook of Fatigue Crack Propagation in Metallic Structures, Vol. 1, A. Carpinteri (editor), Elsevier, Amsterdam (1994).

O. N. Romaniv and G. N. Nykyforchyn, Corrosion Fracture Mechanics of Structural Alloys [in Russian], Metallurgiya, Moscow (1986).

P. Arnoux, “Atomistic simulations of stress corrosion cracking,” Corr. Sci., 52, Is. 4, 1247–1257 (2010); https://doi.org/10.1016/j.corsci.2009.12.024.

K. Sieradzki and R. C. Newman, “Stress-corrosion cracking,” J. Phys. Chem. Solids., 48, Is. 11, 1101–1113 (1987); https://doi.org/10.1016/0022-3697(87)90120-X

J. S. Jesus, L. P. Borrego, J. A. M. Ferreira, J. D. Costa, and C. Capela, “Fatigue crack growth under corrosive environments of Ti–6Al–4V specimens produced by SLM,” Eng. Failure Anal., 118, Article number: 104852 (2020); https://doi.org/10.1016/j.engfailanal.2020.104852.

A. Jacob and A. Mehmanperest “Crack growth direction effects on corrosion-fatigue behaviour of offshore wind turbine steel weldments,” Marine Struct., 75, Article number: 102881 (2021); https://doi.org/10.1016/j.marstruc.2020.102881.

J. Hu, Y. Tian, H. Teng, L. Yu, and M. Zheng, “The probabilistic life time prediction model of oil pipeline due to local corrosion crack,” Theoret. and Appl. Fract. Mech., 70, 10–18 (2014); https://doi.org/10.1016/j.tafmec.2014.04.002.

F. M. Song, “Predicting the mechanisms and crack growth rates of pipelines undergoing stress corrosion cracking at high pH,” Corr. Sci., 51, Is. 11, 2657–2674 (2009); https://doi.org/10.1016/j.corsci.2009.06.051.

O. E. Andreikiv, I. Y. Dolinska, and N. V. Yavorska, “Growth of creep cracks in structural elements under long-term loading,” Mater. Sci., 48, No. 3, 266–273 (2012); https://doi.org/10.1007/s11003-012-9502-1.

O. E. Andreikiv and N. B. Sas, “Subcritical growth of a plane crack in a three-dimensional body under the conditions of high-temperature creep,” Mater. Sci., 44, No. 2, 163–174 (2008); https://doi.org/10.1007/s11003-007-0020-5.

O. E. Andreikiv, H. M. Nykyforchyn, I. P. Shtoiko, and A. R. Lysyk, “Evaluation of the residual life of a pipe of oil pipeline with an external surface stress-corrosion crack for a laminar flow of oil with repeated hydraulic shocks,” Mater. Sci., 53, No. 2, 216–226 (2017); https://doi.org/10.1007/s11003-017-0065-z.

L. D. Kudryavtsev, Course of Mathematical Analysis [in Russian], Vysshaya Shkola, Moscow (1981).

G. S. Pysarenko, A. P. Yakovlev, and V. V. Matveyev, Reference Book on Resistance of Materials [in Russian], Naukova Dumka, Kyiv (1988).

Stress Intensity Factors Handbook, in 2 Vol., Yu. Murakami (editor), Oxford; New York, Pergamon Press (1987).

V. N. Pustovoi, Metal Structures of Lifting Machines. Fracture and Prediction of the Residual Life Time [in Russian], Transport, Moscow (1992).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Fizyko-Khimichna Mekhanika Materialiv, Vol. 58, No. 4, pp. 13–19, July–August, 2022.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Andreikiv, O.Y., Dolinska, I.Y., Zviahin, N.S. et al. Evaluation of the Residual Life Time of the Ethylene Production Rectification Column Under Wind Load and Atmospheric Corrosion. Mater Sci 58, 437–445 (2023). https://doi.org/10.1007/s11003-023-00682-6

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11003-023-00682-6