We analyze the results of investigations of the interaction of hydrogen with metals under the conditions of their deformation. We formulate the conclusions about the fracture and strength of structural materials made on the basis of the experimental data accumulated at the Karpenko Physicomechanical Institute of National Academy of Sciences of Ukraine for the last 70 years (since 1951). Main attention is given to the dual character of the influence of hydrogen on the deformation of metals. Indeed, at low concentrations, it promotes their plasticization, whereas at high concentration, it caused their embrittlement. The indicated features of the interaction of hydrogen with metals form a basis for the prediction of the durability of metal structure in hydrogen–containing media and for development of products with high physicomechanical characteristics.

Similar content being viewed by others

References

H. V. Karpenko, Influence of Hydrogen on the Mechanical Properties of Steel [in Ukrainian], Academy of Sciences of Ukrainian RSR, Kyiv (1960).

G. V. Karpenko and R. I. Kripyakevich, Effect of Hydrogen on the Properties of Steel [in Russian], Metallurgizdat, Moscow (1962).

G. V. Karpenko, A. K. Litvin, V. I. Tkachev, and A. I. Soshko, “Mechanism of hydrogen embrittlement,” Fiz.-Khim. Mekh. Mater., 9, No. 4, 6–11 (1973); English translation: Mater. Sci., 9, No. 4, 367–371 (1975).

A. K. Litvin and V. I. Tkachev, “Processes facilitating the deformation and fracture of metals in the presence of hydrogen,” Fiz.-Khim. Mekh. Mater., 12, No. 2, 27–34 (1976); English translation: Mater. Sci., 12, No. 2, 134–140 (1977).

G. V. Karpenko, K. B. Katsov, А. K. Litvin, and V. I. Tkachev, Method for Decreasing the Friction Coefficient of Metals [in Russian], Author’s Certificate of the SSSR No. 609021, Publ. on 30.05.78, Bull. No. 20.

V. N. Zhitomirskii, T. D. Voznyi, and V. I. Tkachev, “Influence of hydrogen on deformation of surface layers of metal,” Fiz.-Khim. Mekh. Mater., 18, No. 3, 115–116 (1982).

V. I. Pokhmurskii, M. M. Shved, and N. Ya. Yaremchenko, Influence of Hydrogen on the Processes of Deformation and Fracture of Iron and Steel [in Russian], Naukova Dumka, Kiev (1977).

V. I. Pokhmurskii and V. V. Fedorov, “Some features of the influence of hydrogen on magnetic and structural transformations in transition metals and their alloys,” Fiz.-Khim. Mekh. Mater., 17, No. 1, 3–11 (1981); English translation: Mater. Sci., 17, No. 1, 1–8 (1981).

V. I. Pokhmurskii, I. I. Sidorak, R. G. Parkheta, et al., Methodical Recommendations on the Determination of High-Temperature Hydrogen Permeability of Metals [in Russian], Preprint of the Academy of Sciences of Ukrainian SSR No. 117, Physicomechanical Institute (1983).

V. I. Pokhmurs’kyi, “Investigations of the influence of hydrogen on metals carried out in the Karpenko Physicomechanical Institute,” Fiz.-Khim. Mekh. Mater., 33, No. 4, 25–38 (1997); English translation: Mater. Sci., 33, No. 4, 421–435 (1997).

A. E. Andreikiv, V. V. Panasyuk, and V. S. Kharin, “Theoretical aspects of the kinetics of hydrogen embrittlement of metals,” Fiz.-Khim. Mekh. Mater., 14, No. 3, 3–23 (1978); English translation: Mater. Sci., 14, No. 3, 227–244 (1978).

V. V. Panasyuk, A. E. Andreikiv, and V. S. Kharin, “A model of crack growth in deformed metals under the action of hydrogen,” Fiz.-Khim. Mekh. Mater., 23, No. 2, 3–17 (1987); English translation: Mater. Sci., 23, No. 2, 111–124 (1987).

V. V. Panasyuk, A. E. Andreikiv, and O. I. Obukhivskii, “A calculation model of crack growth in metals under the action of hydrogen,” Fiz.-Khim. Mekh. Mater., 20, No. 3, 3–6 (1984); English translation: Mater. Sci., 20, No. 3, 199–200 (1984).

A. E. Andreikiv and O. M. Golian, “Subcritical fatigue crack growth in metals under the action of hydrogen,” Fiz.-Khim. Mekh. Mater., 21, No. 4, 5–8 (1985); English translation: Mater. Sci., 21, No. 4, 298–301 (1985).

A. E. Andreikiv, N. V. Lysak, V. R. Skal’skii, I. L. Parasuyk, and O. N. Sergienko, “Acoustic-emission monitoring of hydrogen cracking in metals and alloys,” Fiz.-Khim. Mekh. Mater., 28, No. 4, 63–69 (1992); English translation: Mater. Sci., 28, No. 4, 378–382 (1992).

I. N. Levina, K. B. Katsov, V. I. Tkachev, Yu. G. Bushuev, V. B. Spiridonov, and E. K. Zenkov, Fractography of Structural Steels and Alloys Operated in a Hydrogen Atmosphere [in Russian], Lvov–Moscow (1988).

V. V. Panasyuk, O. Ye. Andrejkiv, O. I. Darchuk, and N. V. Kuznyak, “Influence of hydrogen containing elements on cyclic crack growth resistance of metals,” in: A. Carpinteri (editor), Handbook of Fatigue Crack Propagation in Metallic Structures, Elsevier, Amsterdam (1994), pp. 1205–1242.

V. Fedorov, I. Bulyk, and V. Panasyuk, “Use of hydrogen as a process medium for the manufacture of permanent magnets based on alloys of rare-earth metals,” in: Proc. of the 4th Int. Conf. “Fracture Mechanics of Materials and Strength of Structures” [in Ukrainian], Karpenko Physicomechanical Institute, National Academy of Sciences of Ukraine, Lviv (2009), pp. 603–608.

O. E. Andreikiv, H. M. Nykyforchyn, and V. I. Tkachov, “Strength and fracture of materials and structural elements in hydrogen-containing media,” in: Physicomechanical Institute: Advance and Achievements (to the 50th Anniversary of the Foundation) [in Ukrainian], Karpenko Physicomechanical Institute, National Academy of Sciences of Ukraine, Lviv (2001), pp. 248–286.

V. V. Panasyuk and I. M. Dmytrakh, “Strength of structural materials in hydrogen-containing media,” in: Karpenko Physicomechanical Institute (to the 60th Anniversary of the Foundation) [in Ukrainian], Spolom, Lviv (2011), pp. 101–120.

O. E. Andreikiv and O. V. Hembara, Fracture Mechanics and Durability of Metallic Materials in Hydrogen-Containing Media [in Ukrainian], Naukova Dumka, Kyiv (2008).

O. P. Ostash and V. I. Vytvyts’kyi, “Duality of the action of hydrogen on the mechanical behavior of steels and structural optimization of their hydrogen resistance,” Fiz.-Khim. Mekh. Mater., 47, No. 4, 5–19 (2011); English translation: Mater. Sci., 47, No. 4, 421–437 (2011).

V. V. Panasyuk, A. E. Andreikiv, and V. S. Kharin, “Origin and growth of microcracks produced by blocked accumulations of dislocations,” Fiz.-Khim. Mekh. Mater., 21, No. 2, 5–16 (1985); English translation: Mater. Sci., 21, No. 2, 105–115 (1985).

V. V. Panasyuk, “Decohesive concept of the interaction of hydrogen with metals,” Fiz.-Khim. Mekh. Mater., 50, No. 2, 7–15 (2014); English translation: Mater. Sci., 50, No. 2, 161–169 (2014).

V. І. Vytvyts’kyi, L. М. Ivas’kevych, М. P. Berezhnyts’ka, and R. V. Chepil’, Method for Determination of the Durability of Steel in Hydrogen [in Ukrainian], Patent of Ukraine No. 17684, Publ. 16.10.2006, Bull. No. 10.

O. P. Ostash, V. І. Vytvyts’kyi, and R. V. Chepil’, Method for Predicting the Hydrogen Resistance of Steels [in Ukrainian], Decision on Establishing the Date of Submitting the Application for the Utility Model uNo. 2011 07136 dated 06.06.2011.

V. І. Vytvyts’kyi, V. I. Tkachov, S. O. Grebenyuk, et al., Method for Treating the Cutting Tool [in Ukrainian], Patent of Ukraine No. 21741А, Publ. 20.01.98, Bull. No. 6.

O. P. Ostash, Structure of Materials and Fatigue Life of Structural Elements [in Ukrainian], Spolom, Lviv (2015).

I. M. Dmytrakh, O. D. Smiyan, and A. M. Syrotyuk, “Experimental study of fatigue crack growth in pipeline steel under hydrogenating conditions” [Electronic resource], in: Fracture of Materials and Structures from Micro to Macro Scale: 18th European Conf. on Fracture (ECF-18), 30.08–03.09.2010, Dresden (Germany), DVM (2010).

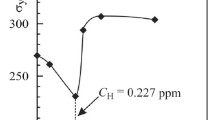

I. М. Dmytrakh, R. L. Leshchak, A. M. Syrotyuk, and O. L. Lutytskyi, “Influence of the bulk concentration of hydrogen in the metal on the specific features of deformation of low-alloy pipe steel,” Fiz.-Khim. Mekh. Mater., 50, No. 2, 16–23 (2014); English translation: Mater. Sci., 50, No. 2, 170–178 (2014).

I. Dmytrakh, A. Syrotyuk, and R. Leshchak, “Features of hydrogenation and fracture resistance of low-alloyed steels for pipelines,” in: V. V. Panasyuk (editor), Proc. of the 5th Int. Scientific-Technical Conf. on Fracture Mechanics of Materials and Strength of Structures (June 24–27, 2014) [in Ukrainian], Karpenko Physicomechanical Institute, National Academy of Sciences of Ukraine, Lviv (2014), pp. 581–592.

I. M. Dmytrakh, R. L. Leshchak, and A. M. Syrotyuk, “Effect of hydrogen concentration on strain behaviour of pipeline steel,” Int. J. Hydrog. Energy, 40, No. 10, 4011–4018 (2015).

I. M. Dmytrakh, M. H. Stashchuk, A. M. Syrotyuk, et al., “Criteria of strength and serviceability of structural steels in a hydrogen medium with regard for their hydrogenation near defects – stress concentrators,” in: V. V. Skorokhod and Yu. M. Solonin (editors), Hydrogen in the Alternative Power Industry and Novel Technologies [in Ukrainian], KIM, Kyiv (2015), pp. 339–348.

I. M. Dmytrakh, R. L. Leshchak, A. M. Syrotyuk, and R. A. Barna, “Effect of hydrogen concentration on fatigue crack growth behaviour in pipeline steel,” Int. J. Hydrog. Energy, 42, No. 9, 6401–6408 (2017).

J. Capelle, I. Dmytrakh, and G. Pluvinage, “Comparative assessment of electrochemical hydrogen absorption by pipeline steels with different strength,” Corros. Sci., 52, No. 5, 1554–1559 (2010).

J. Capelle, J. Gilgert, I. Dmytrakh, and G. Pluvinage, “The effect of hydrogen concentration on fracture of pipeline steels in presence of a notch,” Eng. Fract. Mech., 78, No. 2, 364–373 (2011).

J. Capelle, J. Gilgert, I. Dmytrakh, and G. Pluvinage, “Sensitivity of pipelines with steel API X52 to hydrogen embrittlement,” Int. J. Hydrog. Energy, 33, No. 24, 7630–7641 (2008).

J. Capelle, I. Dmytrakh, Z. Azari, and G. Pluvinage, “Evaluation of electrochemical hydrogen absorption in welded pipe with steel API X52,” Int. J. Hydrog. Energy, 38, No. 33, 14356–14363 (2013).

I. M. Dmytrakh, O. D. Smiyan, A. M. Syrotyuk, and O. L. Bilyy, “Relationship between fatigue crack growth behaviour and local hydrogen concentration near crack tip in pipeline steel,” Int. J. Fatigue, 50, 26–32 (2013).

I. A. Dmytrakh, A. M. Syrotyuk, and R. L. Leshchak, “Specific features of the deformation and fracture of low-alloy steels in hydrogen-containing media: influence of hydrogen concentration in the metal,” Fiz.-Khim. Mekh. Mater., 54, No. 3, 7–19 (2018); English translation: Mater. Sci., 54, No. 3, 295–308 (2018).

V. A. Yartys, I. R. Harris, and V. V. Panasyuk, “Novel metal-hydride materials and technologies: Recent advances and further prospects,” Fiz.-Khim. Mekh. Mater., 33, No. 4, 39–52 (1997); English translation: Mater. Sci., 33, No. 4, 436–439 (1997).

V. A. Yartys, H. Fjellvåg, I. R. Harris, B. C. Hauback, A. B. Riabov, M. H. Sørby, and I. Y. Zavaliy, “Hydrogen ordering and H-induced phase transformations in Zr-based intermetallic hydrides,” J. Alloys Compd., No. 293, 74–87 (1999).

F. Gingl, K. Yvon, I. Yu. Zavaliy, V. A. Yartys, and P. Fischer, “Hydrogenation of Zr6FeAl2 and crystal structure of Zr6FeAl2D10,” J. Alloys Compd., No. 226, 1–4 (1995).

V. A. Yartys, I. Yu. Zavaliy, A. B. Riabov, M. V. Lototsky, and Y. F. Shma’lko, “Oxygen-, boron- and nitrogen-containing zirconium-vanadium alloys as hydrogen getters with enhanced properties,” Z. Phys. Chem., No. 183, 485–489 (1944).

I. Yu. Zavaliy, G. Woicik, G. Mlynarek, I. V. Saldan, V. A. Yartys, and M. Kopczyk, “Phase-structural characteristics of (Ti1 – xZrx)4 Ni2O0.3 alloys and their hydrogen gas and electrochemical absorption-desorption properties,” J. Alloys Compd., No. 314, 124–131 (2001).

R. V. Denys, A. B. Riabov, R. Cerny, I. V. Kovalchuk, and I. Yu. Zavaliy, “New CeMgCo4 and Ce2MgCo9 compounds: hydrogenation properties and crystal structure of hydrides,” J. Solid State Chem., No. 187, 1–6 (2010).

R. V. Denys, I. Y. Zavaliy, V. V. Berezovets, V. Paul-Boncour, and V. K. Pecharskyi, “Phase equilibria in the Mg–Ti–Ni system at 500°С and hydrogenation properties of selected alloys,” Intermetallics, No. 32, 167–175 (2013).

I. Yu. Zavalii, V. V. Berezovets’, and R. V. Denys, “Nanocomposites based on magnesium for hydrogen storage: achievements and prospects (A survey),” Fiz.-Khim. Mekh. Mater., 54, No. 5, 7–21 (2018); English translation: Mater. Sci., 54, No. 5, 9–20 (2019).

І. Yu. Zavalii, R. V. Denys, V. V. Berezovets’, О. B. Ryabov, and P. Ya. Lyutyi, Method of Increasing the Cyclic Stability of Composite Hydrogen-Accumulating Materials Based on Magnesium [in Ukrainian], Patent of Ukraine No. 110659, Publ. 25.10.2016, Bull. No. 20.

Yu. V. Verbovytskyy, V. V. Berezovets, A. R. Kytsya, I. Yu. Zavaliy, and V. A. Yartys, “Hydrogen generation by hydrolysis of MgH2,” Fiz.-Khim. Mekh. Mater., 56, No. 1, 9–20 (2020); English translation: Mater. Sci., 56, No. 1, 1–14 (2020).

I. I. Bulyk and V. V. Panasyuk, “Hydrogen as a technological medium for the formation of nanostructures in Sm–Co ferromagnetic alloys,” Fiz.-Khim. Mekh. Mater., 48, No. 1, 9–18 (2012); English translation: Mater. Sci., 48, No. 1, 1–11 (2012).

J. P. Liu, E. Fullerton, O. Gutfleisch, and D. J. Sellmyer (editors), Nanoscale Magnetic Materials and Applications, Springer, New York (2009).

I. I. Bulyk, “Application of hydrogen in the production of sintered anisotropic nanostructured magnets from alloys of rare-earth and transition metals,” Fiz.-Khim. Mekh. Mater., 54, No. 6, 10–23 (2018); English translation: Mater. Sci., 54, No. 6, 761–775 (2019); https://doi.org/10.1007/s11003-019-00262-7.

A. Eldosouky and I. Skulj, “Hydrogen reaction with SmCo compounds: literature review,” J. Sustain. Metall., 4, 516–527 (2018); https://doi.org/10.1007/s40831-018-0195-z.

I. I. Bulyk, V. V. Panasyuk, and А. М. Trostyanchyn, Method of Formation of Anisotropic Fine-Grained Structure of Powders of the Sm–Co System by the Hydrogen-Vacuum Thermal Treatment [in Ukrainian], Patent of Ukraine No. 96810, H 01 F 1/053; H 01 F 1/055; B 82 B 3/00, Publ. 12.12.2011, Bull. No. 23.

I. I. Bulyk, V. V. Panasyuk, and А. М. Trostyanchyn, Method of Formation of Anisotropic Fine-Grained Structure of Powders of the Sm–Co System by Milling in Hydrogen [in Ukrainian], Patent of Ukraine No. 96811, H 01 F 1/053; H 01 F 1/055; B 82 B 3/00, Publ. 12.12.2011, Bull. No. 23.

I. I. Bulyk, А. М. Trostyanchyn, V. M. Dmytryshyn, and P. Ya. Lyutyi, Method of Hydrogenation, Disproportionation, Desorption and Recombination (HDDR) under Low Hydrogen Pressure for the Formation of an Anisotropic Fine-Grained Structure of Powders of Alloys of the Sm–Co System and Obtaining Powders with Such a Structure [in Ukrainian], Patent of Ukraine No. 102899, H 01 F 7/00, H 01 F 7/02, B 22 F 9/00, Publ. 27.08.2013, Bull. No. 21.

I. I. Bulyk, А. М. Trostyanchyn, P. Ya. Lyutyi, and V. V. Burkhovets’kyi, Method of Formation of the Anisotropic Fine-Grained Microstructure in Powders of Alloys of the Nd–Fe–B System [in Ukrainian], Patent of Ukraine No. 106651. H01F 1/057, H01F 1/00, H01F 41/00, B22F 9/00, B22F 9/04, Publ. 25.09.2014, Bull. No. 18.

I. I. Bulyk, V. N. Varyukhin, V. Yu. Tarenkov, V. V. Burkhovetskii, and S. L. Sidorov, “Influence of hydrogen treatment on the microstructure and magnetic properties of KS 37 alloy (SmCo5 base),” Fiz. Tekh. Vysok. Davlen., 23, No. 4, 67–82 (2013).

I. I. Bulyk, A. V. Trostyanchyn, V. V. Burkhovets’kyi, and V. Yu. Tarenkov, “Features of HDDR under low hydrogen pressures in alloys of the Nd–Fe–B system,” Metallofiz. Noveish. Tekhnol., 36, No. 7, 903–916 (2014).

I. I. Bulyk, V. V. Burkhovets'kyi, and A. M. Trostyanchyn, “Change of the phase-structural state of SmCo5-based alloy during solid HDDR under low hydrogen pressure,” Metallofiz. Noveish. Tekhnol., No. 2, 169–184 (2015).

I. I. Bulyk and V. V. Burkhovetskyy, “Variation in microstructure of ground SmCo5 alloy during disproportionation in hydrogen and recombination,” Poroshk. Metall., 54, Nos. 9-10, 134–146 (2015).

I. I. Bulyk, А. М. Trostyanchyn, І. V. Borukh, and V. V. Burkhovets’kyi, Method for Sintering of Powders of Alloys of the Nd–Fe–B System [in Ukrainian], Patent for Invention of Ukraine No. 116890, MPK(2018.01) H01F 7/02, H01F 1/057, B22F 9/00, H01F 1/055, B22F 9/16, B22F 3/10, Publ. 25.05.2018, Bull. No. 10.

I. I. Bulyk and M. V. Pylat, Method for Sintering of Magnets from Alloys Based on Sm2Co17 [in Ukrainian], Patent for Invention of Ukraine No. 116891, MPK(2018.01) H01F 7/02, H01F 1/057, B22F 9/00, H01F 1/055, B22F 9/16, B22F 3/10, Publ. 25.05.2018, Bull. No. 10.

I. I. Bulyk, І. V. Borukh, and V. V. Burkhovets’kyi, Method for Sintering of Magnets from Alloys Based on SmCo5 [in Ukrainian], Patent for Invention of Ukraine No. 117119, MPK6 H 01 F 7/00, H 01 F 7/02, B 22 F 9/00, Publ. 25.06.2018, Bull. No. 12.

I. I. Bulyk, V. V. Chabanenko, A. Nabiałek, T. Zajarniuk, A. Szewczyk, R. Puźniak, V. V. Burkhovetskyi, V. Yu. Tarenkov, and I. V. Borukh, “The influence of recombination conditions on the phase content, microstructure, and magnetic properties of SmCo5-based sintered magnets,” in: Collected Abstracts of the 14th Int. Conf. on Crystal Chemistry of Intermetallic Compounds (September 22–26, 2019) [in Ukrainian], Lviv (2019), p. 131.

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Fizyko-Khimichna Mekhanika Materialiv, Vol. 57, No. 3, pp. 7–16, May–June, 2021.

Rights and permissions

About this article

Cite this article

Panasyuk, V.V. Contribution of the Karpenko Physicomechanical Institute of National Academy of Sciences of Ukraine to the Investigations of the Effect of Hydrogen on the Deformation and Fracture of Metals (A Survey). Mater Sci 57, 299–307 (2021). https://doi.org/10.1007/s11003-021-00545-y

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11003-021-00545-y