We study corrosion, hydrogenation, and mechanical properties of 17G1S-U steel in chloride-acetate solutions with hydrogen-sulfide concentrations of 25, 100, 500, and 1500 mg/dm3. For \( {C}_{{\mathrm{H}}_2\mathrm{S}} \) = 25 and 100 mg/dm3, steel corrodes for 720 h with a rate of about 0.5 g/(m2·h). In these solutions, the yield limit and ultimate strength undergo insignificant changes but the relative narrowing undergoes six- and tenfold changes, respectively. Under stresses equal to 0.8σ0.2, steel does not suffer cracking in a solution with \( {C}_{{\mathrm{H}}_2\mathrm{S}} \) = 100 mg/dm3. It is shown that the corrosion of steel at \( {C}_{{\mathrm{H}}_2\mathrm{S}} \) ≥ 500 mg/dm3 is accompanied by the formation of surface hydrogen-induced cracks, and the degree of hydrogenation is almost twice larger than at lower concentrations. This is a condition required for the development of hydrogen-sulfide corrosion cracking. Static and asymmetric loads on the level of threshold values in the NACE solution intensify the process of hydrogenation of steel in solutions with \( {C}_{{\mathrm{H}}_2\mathrm{S}} \) = 100–1500 mg/dm3, which becomes almost identical \( {C}_{{\mathrm{H}}_{\Sigma}} \) = 12.5–14.8 ppm. By analyzing various trends in the development of steel corrosion in solutions with \( {C}_{{\mathrm{H}}_2\mathrm{S}} \) = 100 and 1500 mg/dm3, we conclude that the fracture of steel in these solutions is affected not only by the degree of hydrogenation of the metal but also by the nature of sulfides formed on the surface and their protective properties.

Similar content being viewed by others

References

NACE International “Petroleum and Natural Gas Industries—Materials for Use in H2S-Containing Environments in Oil and Gas Production, Part 1: General Principles for Selection of Cracking-Resistant Materials,” ANSI/NACE MR0175/ISO 15156-1:2009 (2009). [Electronic resource], Access mode: https://www.iso.org/obp/ui/#iso:std:iso:15156:-1:ed-2:v1:en.

I. V. Plachkov and S. H. Plachkova, Power Engineering: History, Present, and Future [in Ukrainian] [Electronic resource], Access mode: http://energetika.in.ua/ua/books/book-1.

NACE Standard MR0175-2003. Item No. 21302. Standard Material Requirements. Metals for Sulfide Stress Cracking and Stress Corrosion Cracking Resistance in Sour Oilfield Environments, NACE Int., Houston (2003).

O. I. Radkevych, S. V. Chopan, R. V. Boiko, and V. P. Voitsits’kyi, “Corrosion aggressiveness of natural gas with admixtures of hydrogen sulfides,” Naft. Gas. Promysl., No. 2, 37–41 (2002).

М. S. Khoma, S. А. Holovei, V. R. Ivashkiv, and Kh. B. Vasyliv, “Effect of sulfides on the hydrogen overvoltage and hydrogenation of U8 steel in chloride-hydrogen-sulfide media,” Fiz.-Khim. Mekh. Mater., 53, No. 6, 16–21 (2017); English translation: Mater. Sci., 53, No. 6, 761–768 (2018).

M. S. Khoma, N. B. Rats'ka, S. А. Holovei, and М. R. Chuchman, “Specific features of corrosion and the microelectrochemical heterogeneity of 45 and U8 steels in hydrogen-sulfide media,” Fiz.-Khim. Mekh. Mater., 54, No. 4, 52–56 (2018); English translation: Mater. Sci., 54, No. 4, 501–505 (2019).

J. Ning, Y. Zheng, D. Young, B. Brown, and S. Nešic, “Thermodynamic study of hydrogen sulfide corrosion of mild steel,” Corrosion, 70, No. 4, 375–389 (2008).

М. S. Khoma, S. А. Holovei, V. R. Ivashkiv, Kh. B. Vasyliv, М. R. Chuchman, and N. B. Rats’ka, “Influence of the nature of sulfide-containing films on the character of corrosion and hydrogenation of steels with different structures in chloride-acetate solutions,” Fiz.-Khim. Mekh. Mater., Special issue No. 14, 9–13 (2018).

М. R. Chuchman, “Hydrogenation of pipe steels under the action of static and cyclic loads in hydrogen-sulfide media,” Fiz.-Khim. Mekh. Mater., Special issue No. 10, 163–168 (2014).

GOST 23338-91. Welding of Metals. Methods for the Determination of the Contents of Diffusive Hydrogen in Fused and Weld Metals [in Russian], Introduced on 01.07.1992.

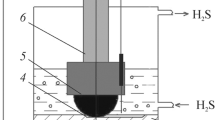

М. R. Chuchman, A Cell for the Investigations of Corrosion Cracking of Metals under Stresses in Corrosive Solutions [in Ukrainian], Patent No. 61480, Ukraine, MPK G01N 17/00, Publ. on 25.07.2011; Bull. No. 14.

H. Ma, X. Cheng, G. Li, S. Chen, Z. Quan, S. Zhao, and L. Niu, “The influence of hydrogen sulfide on corrosion of iron under different conditions,” Corr. Sci., 42, 1669–1683 (2000).

М. S. Khoma, V. R. Ivashkiv, N. B. Ratska, B. M. Datsko, and М. R. Chuchman, “Corrosion-electrochemical properties of 17G1SU steel in chloride-acetate solutions with different concentrations of hydrogen sulfide,” Fiz.-Khim. Mekh. Mater., 56, No. 4, 100–104 (2020); English translation: Mater. Sci., 56, No. 4, 544–549 (2021).

S. K. Dwivedi and M. Vishwakarmam, “Hydrogen embrittlement in different materials: A review,” Int. J. Hydrogen Energy, 43, 21603–21616 (2018).

V. I. Pokhmurskyi and М. S. Khoma, Fracture Resistance of Metals in Hydrogen-Sulfide Media [in Ukrainian], in: Material Science: Achievements and Prospects, Vol. 2, Akademperiodika, Kyiv (2018).

F. Huang, P. Cheng, X. Y. Zhao, J. Liu, Q. Hu, and Y. Frank Cheng, “Effect of sulfide films formed on X65 steel surface on hydrogen permeation in H2S environments,” Int. J. Hydrogen Energy, 42, No. 7, 4561–4570 (2017).

J. B. Sardisco and R. E. Pitts, “Corrosion of iron in an H2S–CO2–H2O-system. Composition and protectiveness of the sulphide film as a function of pH,” Corrosion, 21, No. 11, 350–354 (1965).

M. S. Khoma, М. R. Chuchman, B. M. Datsko, and A. I. Dyachuk, “Relationship between the corrosion and hydrogen factors in the fracture processes running in pipe steels placed in hydrogen-sulfide media,” Fiz.-Khim. Mekh. Mater., Special issue No. 10, 5–10 (2014).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Fizyko-Khimichna Mekhanika Materialiv, Vol. 56, No. 5, pp. 15–22, September–October, 2020.

Rights and permissions

About this article

Cite this article

Pokhmurskyi, V.І., Khoma, M.S., Chuchman, M.R. et al. Corrosion and Hydrogenation of 17G1S-U Steel in Hydrogen-Sulfide Media of Different Concentrations. Mater Sci 56, 593–601 (2021). https://doi.org/10.1007/s11003-021-00469-7

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11003-021-00469-7