We study welded joints of 2 mm-thick sheets of D16T aluminum alloy (an analog of the 2024-T3 alloy used abroad), which is now not recommended for welding. The joints are obtained by the friction stir welding. It is shown that the complex structural strength parameter determined by the strength and cyclic crack-growth resistance of the weld metal of these joints is 2.4 times higher than for the base metal and 3.7–12 times higher than for the weld metal of D16 alloy joints obtained by using different technologies of welding and thermal treatment.

Similar content being viewed by others

References

V. V. Panasyuk (editor), Fracture Mechanics and Strength of Materials, O. P. Ostash, Structure of Materials and Fatigue Durability of Structural Elements [in Ukrainian], Vol. 15, Spolom, Lviv (2015).

O. N. Romaniv, Fracture Toughness of Structural Steels [in Russian], Metallurgiya, Moscow (1979).

O. P. Ostash, O. A. Haivorons’kyi, V. D. Poznyakov, and V. V. Kulyk, A Method of Thermal Treatment of High-Strength Low-Alloy Carbon Steels [in Ukrainian], Patent of Ukraine No. 105440, Publ. 25.03.2016, Bull. No. 6.

Joint Aviation Requirements, JAR 25.571, (1998).

V. M. Beletskii and G. A. Krivov, Aluminum Alloys (Composition, Properties, Technology, Application) [in Russian], Edited by I. N. Fridlyander, Komintekh, Kiev (2005).

V. V. Panasyuk (editor), Fracture Mechanics and Strength of Materials, O. P. Ostash, V. M. Fedirko, V. M. Uchanin, S. A. Bychkov, O. G. Molyar, O. I. Semenets’, V. S. Kravets’, and V. Ya. Derecha, Strength and Durability of Aviation Materials and Structural Elements [in Ukrainian], Vol. 9, Spolom, Lviv (2007).

A. Squillare, A. De Fenzo, G. Giorleo, and F. Bolluci, “A comparison between FSW and TIG welding techniques: modifications of microstructure and pitting corrosion resistance in AA 2024-T3 butt joints,” J. Mater. Process Tech., 152, 97–105 (2004).

C. Genevois, A. Deschamps, A. Denquin, and B. Doisneau-Cootignies, “Quantitative investigation of precipitations and mechanical behavior for AA 2024 friction stir welds,” Acta Mater., 53, 4447–4458 (2005).

A. Scialpi, L. De Filipps, and P. Cavaliere, “Influence of shoulder geometry on microstructure and mechanical properties of friction stir welded 6082 aluminum alloy,” Mater. Design, 28 (4), 1124–1129 (2007).

N. J. Woodward, I. M. Richardson, and A. Thomas, “Variable polarity plasma arc welding of 6.35 mm aluminum alloys: parameter development and preliminary analysis,” Sci. Technol. Welding Joining, 5 (1), 21–25 (2000).

T. M. Labur, O. P. Ostash, Yu. V. Holovatyuk, V. A. Koval’, and V. S. Shynkarenko, “Influence of alloying and thermal treatment on the strength and cyclic crack resistance of welded joints of alloys of the Al–Cu–Mg system. Part 1,” Fiz.-Khim. Mekh. Mater., 53, No. 2, 7–15 (2017); English translation : Mater. Sci., 53, No. 2, 131–140 (2017).

T. M. Labur, O. P. Ostash, Yu. V. Holovatyuk, V. A. Koval’, and V. S. Shynkarenko, “Influence of alloying and thermal treatment on the strength and cyclic crack resistance of welded joints of alloys of the Al–Cu–Mg system. Part 2,” Fiz.-Khim. Mekh. Mater., 53, No. 4, 28–33 (2017); English translation : Mater. Sci., 53, No. 4, 453–459 (2017).

W. M. Thomas, E. D. Nicholas, J. C. Needham, M. G. Church, P. Templesmith, and C. J. Dawes, Friction Stir Butt Welding, Int. Patent Application No. PCT/GB 92/02203; GB Patent Application, No. 9125978.8, Publ. (1991).

G. Bussu and P. E. Irving, “The role of residual stress and heat affected zone properties on fatigue crack propagation in friction stir welded 2024-T351 aluminum joints,” Int. J. Fatigue, 25, 77–88 (2003).

J. Defalco, “Friction stir welding vs. fusion welding,” Welding J., No. 3, 42–44 (2006).

M. Enomoto, “Friction stir welding: research and industrial applications,” Welding Int., No. 5, 341–345 (2003).

Y. Sato, “Relationship between mechanical properties and microstructure in friction stir welded Al alloys,” J. Japan Welding Soc., No. 8, 33–36 (2002).

T. Shibayanagi, “Microstructural aspects in friction stir welding,” J. Japan Inst. Light Met., No. 9, 416–423 (2007).

T. M. Labur, O. P. Ostash, Yu. V. Holovatyuk, V. M. Uchanin, M. R. Yavors’ka, M. P. Pashulya, V. A. Koval’, and V. S. Shynkarenko, “Influence of the space orientation of joints in the process of welding on the strength and cyclic crack resistance of welded joints,” Fiz.-Khim. Mekh. Mater., 52, No. 2, 29–34 (2016); English translation : Mater. Sci., 52, No. 2, 180–187 (2016).

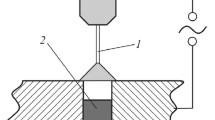

A. Ya. Ishchenko and A. G. Poklyats’kyi, A Tool for the Friction Stir Welding of Aluminum Alloys [in Ukrainian], Patent of Ukraine No. 54096, Publ. 25.10.2010; Bull. No. 20.

O. Ostash, V. Uchanin, J. Semenets, Yu. Holovatyuk, L. Kovalchuk, and V. Derecha, “Evaluation of aluminum alloys degradation in aging aircraft,” Res. Nondestruct. Evaluat., 29, No. 3, 156–166 (2018).

GOST 6996-66. Welded Joints. Methods of Mechanical Tests [in Russian], Izd. Standartov, Moscow (1967).

Standard Test Method for Measurement of Fatigue Crack Growth Rates, ASTM Standards, E647-93.

H. Aydin, A. Bayram, and I. Durgun, “The effect of post-weld heat treatment on the mechanical properties of 2024-T4 friction stirwelded joints,” Mater. Des., 31, 2568–2577 (2010).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Fizyko-Khimichna Mekhanika Materialiv, Vol. 54, No. 3, pp. 112–119, May–June, 2018.

Rights and permissions

About this article

Cite this article

Holovatyuk, Y.V., Poklyats’kyi, A.H., Ostash, O.P. et al. Elevation of the Structural Strength of Welded Joints of Sheets Made of Alloys of the Al–Cu–Mg System. Mater Sci 54, 412–420 (2018). https://doi.org/10.1007/s11003-018-0200-5

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11003-018-0200-5