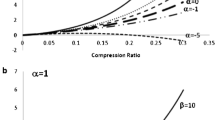

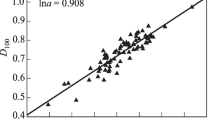

We describe physical relationships used for the analysis of stresses and strains in modeling the process of compaction of materials of the vegetable origin with properties of plasticity. The study is based on the yield condition formulated by Green. The analysis uses the basic functions of porosity and the Amontons–Coulomb and Prandtl laws of friction for porous materials. The experimental and theoretical tests of fodder mixture compression are performed in a closed chamber. The identification of material constants is performed by using numerical methods and nonlinear regression equations describing the pressure on the stamps of the chamber.

Similar content being viewed by others

References

R. M. German, Powder Metallurgy and Particulate Materials Processing, Metal Powder Industries Federation, Princeton, New Jersey (2005).

M. Youseffi and N. Showaiterv, “PM Processing of elemental and pre-alloyed 6061 aluminum alloy with and without common lubricants and sintering aids,” Powder Metallurgy, 49, No. 3, 240–252 (2006).

T. J. Volger, M. Y. Lee, and D. E. Grady, “Static and dynamic compaction of ceramic powders,” Int. J. Sol. Struct., 44, No. 2, 636–658 (2007).

Z. N. Wing and J. W. Halloran, “Dry Powder Deposition and Compaction for Functionally Graded Ceramics,” J. Amer. Ceram. Soc., 89, No. 11, 3406–3412 (2006).

P. Narayan and B. C. Hancock, “The influence of particle size on the surface roughness of pharmaceutical compacts,” Mat. Sci. Eng. A, 407, No. 1, 226–233 (2005).

C. Y. Wu, O. M. Ruddy, A. C. Bentham, B. C. Hancock, S. M. Best, and J. A. Elliott, “Modeling the mechanical behavior of pharmaceutical powders during compaction,” Powder Tech., 152, No. 1–3, 107–117 (2005).

J. Laskowski, Studia nad Procesem Granulowania Mieszanek Paszowych, Wydawnictwo Akademii Rolniczej, Lublin (1989).

C. S. Chou, Sh. H. Lin, and W. Ch. Lu, “Preparation and characterization of solid biomass fuel made from rice straw and rice bran,” Fuel Proc. Tech., 90, No. 7–8, 980–987 (2009).

I. Mediavilla, M. J. Fernández, and L. S. Esteban, “Optimization of pelletization and combustion in a boiler of 17.5kWth for vine shoots and industrial cork residua,” Fuel Proc. Tech., 90, No. 4, 621–628 (2009).

W. F. Chen and A. F. Saleeb, Constitutive Equations for Engineering Materials, Elasticity and Modeling, Vol. 1, Wiley Interscience, New York (1982).

D. C. Drucker and W. Prager, “Soil mechanics and plastic analysis on limit design,” Q. Appl. Math., 10, No. 2, 157–165 (1952).

A. N. Schofield and C. P. Wroth, Critical State Solid Mechanics, McGraw-Hill, London (1968).

P. V. Lade, “Elastic-plastic stress–strain theory for cohesion less soil with curved yield surfaces,” Int. J. Solids Struct., 13, No. 11, 1019–1035 (1977).

R. J. Green, “A plasticity theory for porous solids,” Int. J. Mech. Sci., 14, No. 4, 215–224 (1972).

H. A. Kuhn and C. L. Downey, “Deformation characteristics and plasticity theory of sintered powder materials,” Int. J. Powder Metallurgy, 7, No. 1, 15–25 (1971).

S. Shima and M. Oyane, “Plasticity theory for porous metals,” Int. J. Mech. Sci., 18, No. 6, 285–291 (1976).

M. Doraivelu, “A new yield function for compressible P/M materials,” Int. J. Mech. Sci., 26, No. 9–10, 527–535 (1984).

A. L. Gurson, “Continuum theory of ductile rupture by void nucleation and growth. I. Yield criteria and flow rules for porous ductile media,” J. Eng. Mater. Tech., 99, No. 1, 2–15 (1977).

J. Czaban and Z. Kamiński, “Theoretical foundations of compaction and compression of granular materials of vegetable origin with properties of plasticity,” Acta Agrophysica, 19, No. 3, 487–500 (2012).

W. Bier, M. P. Dariel, N. Frage, S. Hartmann, and O. Michailov, “Die compaction of copper powder designed for material parameter ,” Int. J. Mech. Sci., 49, No. 7, 766–777 (2007).

St. Okoński, Podstawy Plastycznego Kształtowania Materiałów Spiekanych z Proszków Metali, Wydawnictwa Politechniki Krakowskiej, Krakow (1993).

A. M. Laptev, “Analysis of the formation and second compaction of porous bushes by the method of thin sections,” Poroshk. Metallurg., No. 7, 44–48 (1988).

B. A. Druyanov, Applied Theory of Plasticity of Porous Bodies [in Russian], Mashinostroenie, Moscow (1989).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Czaban, J., Kaminski, Z. Identification of the Mechanical Properties of Compound Feeds for Modeling the Processes of Thickening and Compaction. Mater Sci 53, 226–234 (2017). https://doi.org/10.1007/s11003-017-0066-y

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11003-017-0066-y