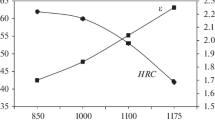

We study the influence of the Q-n-P-treatment including the interrupted quenching followed by holding at 250–350°C on the microstructure, hardness, and abrasion resistance of 75KhG2C steel. It is shown that the Q-n-P-treatment leads to the formation of a structure with elevated (27.5%) content of residual austenite. The procedure treatment with quenching interrupted at 100°C followed by the holding at 250°C for 10 min increases the abrasive wear resistance of steel by 8% as compared to the fully quenched state with a much lower hardness (57 and 63 HRC, respectively).

Similar content being viewed by others

Change history

12 October 2017

A correction to this article has been published.

References

A. J. Clarke, J. G. Speer, M. K. Miller, R. E. Hackenberg, D. V. Edmonds, D. K. Matlock, F. C. Rizzo, K. D. Clarke, and E. De Moor, “Carbon partitioning to austenite from martensite or bainite during the quench and partition (Q&P) process: A critical assessment,” Acta Mater., 56, No. 1, 16–22 (2008).

H. Jirková, B. Masek, M. F.-X. Wagner, D. Langmajerová, L. Kucerová, R. Treml, and D. Kiener, “Influence of metastable retained austenite on macro and micromechanical properties of steel processed by the Q & P process,” J. Alloy. Compound., 615, 163–168 (2014).

T. Y. Hsu, X. J. Jin, and Y. H. Rong, “Strengthening and toughening mechanisms of quenching-partitioning-tempering steels,” J. Alloy. Compound., 577S, 568–571 (2013).

Y. Toji, G. Miyamoto, and D. Raabe, “Carbon partitioning during quenching and partitioning heat treatment accompanied by carbide precipitation,” Acta Mater., 86, 137–147 (2015).

J. Speer, D. K. Matlock, B. C. De Cooman, and J. G. Schroth, “Carbon partitioning into austenite after martensite transformation,” Acta Mater., 51, 2611–2622 (2003).

D. De Knijf, R. Petrov, C. Föjer, and A. I. Kestens Leo, “Effect of fresh martensite on the stability of retained austenite in quenching and partitioning steel,” Mater. Sci. & Eng: A, 615, 107–115 (2014).

D. V. Edmonds, K. He, F. C. Rizzo, B. C. De Cooman, D. K. Matlock, and J. G. Speer, “Quenching and partitioning martensite – A novel steel heat treatment,” Mater. Sci. & Eng: A, 438–440, 25–34 (2006).

N. Maheswari, S. Ghosh Chowdhury, K. C. Hari Kumar, and S. Sankaran, “Influence of alloying elements on the microstructure evolution and mechanical properties in quenched and partitioned steels,” Mater. Sci. & Eng: A, 600, 12–20 (2014).

S. G. Liu, S. S. Dong, and F. Yang, “Application of quenching–partitioning–tempering process and modification to a newly designed ultrahigh carbon steel,” Mater. Design, 56, 37–43 (2014).

V. G. Efremenko, K. Shimizu, T. Noguchi, A. V. Efremenko, and Yu. G. Chabak, “Impact-abrasive-corrosion wear of Fe-based alloys: Influence of microstructure and chemical composition upon wear resistance,” Wear, 305, Nos. 1–2, 155–165 (2013).

O. Hesse, J. Merker, M. Brykov, and V. Efremenko, “Zur Festigkeit niedriglegierter Stäble mit erhöhtem Kohlenstoffgehalt gegen abrasiven Verschleiß,” Tribol. Schmierungstechnik, 60, No. 6, 37–43 (2013).

L. S. Malinov and V. A. Kharlashkin, “Effect of cementation and heat treatment of steel 10G12 on metastable austenite in the structure, abrasive and impact wear resistance,” Metallurg. Mining Industry, 3, No. 2, 58–62 (2011).

A. D. Koval’, V. G. Efremenko, M. N. Brykov, M. I. Andrushchenko, R. A. Kulikovskii, and A. V. Efremenko, “Principles of development of grinding media with increased wear resistance. Part 1. Abrasive wear resistance of iron-based alloys,” J. Friction Wear, 33, No. 1, 39–46 (2012).

R. Colaço and R. Vilar, “On the influence of retained austenite in the abrasive wear behavior of a laser surface melted tool steel,” Wear, 258, Nos. 1–4, 225–231 (2005).

V. G. Efremenko, K. Shimizu, A. P. Cheiliakh, T. V. Pastukhova, Yu. G. Chabak, and K. Kusumoto, “Abrasive resistance of metastable V–Cr–Mn–Ni spheroidal carbide cast irons using the factorial design method,” Int. J. Miner., Metallurgy, Mater., 23, 645–657 (2016).

L. E. Popova and A. A. Popov, Diagrams of Transformations of Austenite in Steels and Beta-Solution in Titanium Alloys [in Russian], Metallurgiya, Moscow (1991).

K. D. H. Bhadeshia, “Effect of stress & strain on formation of bainite in steel,” in: H. J. McQueen, E. V. Konpleva, and N. D. Ryan (editors), Hot Workability of Steels and Light Alloys-Composites, Canadian Institute of Mining, Minerals, and Petroleum, Montreal (1996), pp. 543–556.

A. Navarro-Lopez, J. Sietsma, and M. J. Santofimia, “Effect of prior a thermal martensite on the isothermal transformation kinetics below Ms in a low-C high-Si steel,” Metallurg. Mater. Transact. A, 47, No. 3, 1028–1039 (2016).

A. D. Koval’, V. G. Efremenko, M. N. Brykov, M. I. Andrushchenko, R. A. Kulikovskii, and A. V. Efremenko, “Principles for developing grinding media with increased wear resistance. Part 2. Optimization of steel composition to suit conditions of operation of grinding media,” J. Friction Wear, 33, No. 2, 153–159 (2012).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Fizyko-Khimichna Mekhanika Materialiv, Vol. 53, No. 1, pp. 61–68, January–February, 2017.

The original version of this article was revised. The name of the first author should read V. G. Efremenko. The name of the third author should read Yu. G. Chabak.

A correction to this article is available online at https://doi.org/10.1007/s11003-017-0053-3.

Rights and permissions

About this article

Cite this article

Efremenko, V.G., Zurnadzhi, V.I., Chabak, Y.G. et al. Application of the Q-n-P-Treatment for Increasing the Wear Resistance of Low-Alloy Steel with 0.75% C. Mater Sci 53, 67–75 (2017). https://doi.org/10.1007/s11003-017-0045-3

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11003-017-0045-3