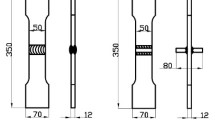

We justify the efficiency of high-frequency mechanical peening for the improvement of the corrosion fatigue characteristics of welded joints and evaluate its influence on the corrosion resistance of the base metal. The cyclic fatigue life of welded butt and T joints of 15KhSND steel in the intact and hardened (by high-frequency mechanical peening) states in air and in a corrosive medium (3% NaCl) at a frequency of 5 Hz is investigated. We use specimens of the base metal after grinding and after grinding with subsequent hardening by high-frequency mechanical peening. It is shown that the procedure of treatment by high-frequency mechanical peening noticeably increases the fatigue characteristics of welded joints both in air and in 3% NaCl. Its influence on the rate of general corrosion of the surface of specimens of the base metal after testing for 1300, 2200, 4700, and 8760 h in distilled water and in 3% NaCl is also established.

Similar content being viewed by others

References

V. D. Gorbach and V. S. Mikhailov, “Surface hardening of welded joints aimed at prolongation of the corrosion-fatigue life of ship structures,” Sudostroenie, No. 4, 45–48 (2000).

R. Baptista, V. Infante, and C. M. Branco, “Study of the fatigue behavior in welded joints of stainless steels treated by weld toe grinding and subjected to salt water corrosion,” Int. J. Fatigue, 30, 453–462 (2008).

E. V. Kolomiitsev, “Corrosion-fatigue strength of T-joints of 12Kh18N10Т steel and the methods for its improvement,” Avtomat. Svarka, No. 12, 41–43 (2012).

Zh. Lu, L. Shi, Sh. Zhu, Zh. Tang, and Ya. Jiang, “Effect of high energy shot peening pressure on the stress-corrosion cracking of the weld joint of 304 austenitic stainless steel,” Mater. Sci. Eng. A, 637, 170–174 (2015).

B. Nasiłowska, Z. Bogdanowicz, and M. Wojucki, “Shot peening effect on 904 L welds corrosion resistance,” J. Constr. Steel Res., 115, 276–282 (2015).

L. M. Lobanov, V. I. Kirian, V. V. Knysh, and G. I. Prokopenko, “Improvement of fatigue resistance of welded joints in metal structures by high-frequency mechanical peening (Review),” Paton Welding J., No. 9, 2–8 (2006).

M. Malaki and H. Ding, “A review of ultrasonic peening treatment,” Mater. Design, 87, 1072–1086 (2015).

E. V. Kolomiitsev and A. N. Serenko, “Influence of ultrasonic and laser treatment on the fatigue resistance of welded butt joints in air and in corrosive media,” Avtomat. Svarka, No. 11, 13–15 (1990).

V. V. Knysh, А. Z. Kuz’menko, I. I. Val’teris, and S. А. Solovei, “Corrosion fatigue resistance of welded joints hardened by high-frequency mechanical peening,” Avtomat. Svarka, No. 4, 5–8 (2008).

G. I. Prokopenko, B. N. Mordyuk, V. V. Knysh, S. A. Solovei, and T. V. Popova, “Improvement of the fatigue and corrosion resistances of welded joints by ultrasonic impact treatment and electric-discharge alloying,” Tekh. Diagnost. Nerazrush. Kontr., No. 3, 34–40 (2014).

Z. Dong, Z. Liu, M. Li, J-L. Luo, W. Zneng, and D. Guzonas, “Effect of ultrasonic impact peening on the corrosion of ferriticmartensitic steels in supercritical water,” J. Nucl. Mater., 457, 266–272 (2015).

M. Daavary and S. A. Sadough Vanini, “Corrosion fatigue enhancement of welded steel pipes by ultrasonic impact treatment,” Mater. Lett., 139, 462–466 (2015).

W. Gao, D. Wang, F. Cheng, C. Deng, Y. Liu, and W. Xu, “Enhancement of the fatigue strength of underwater wet welds by grinding and ultrasonic impact treatment,” J. Mater. Proc. Technol., 223, 305–312 (2015).

GOST 9.908-85. Unified System of Protection Against Corrosion and Aging. Metals and Alloys. Methods for the Determination of the Parameters of Corrosion and Corrosion Resistance [in Russian], Introduced on 01.01.87.

B. N. Mordyuk, G. I. Prokopenko, M. A. Vasylyev, and M. O. Lefimov, “Effect of structure evolution induced by ultrasonic peening on the corrosion behavior of AISI-321 stainless steel,” Mater. Sci. Eng. A, 458, 253–261 (2007).

H.-S. Lee, D.-S. Kim, J.-S. Jung, Y.-S Pyoun, and K. Shin, “Influence of peening on the corrosion properties of AISI 304 stainless steel,” Corros. Sci., 51, 2826–2830 (2009).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Fizyko-Khimichna Mekhanika Materialiv, Vol. 53, No. 1, pp. 12–17, January–February, 2017.

Rights and permissions

About this article

Cite this article

Knysh, V.V., Solovei, S.А., Kadyshev, А.А. et al. Influence of High-Frequency Peening on the Corrosion Fatigue of Welded Joints. Mater Sci 53, 7–13 (2017). https://doi.org/10.1007/s11003-017-0036-4

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11003-017-0036-4