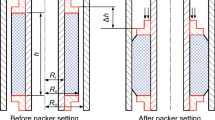

We describe additional capabilities of the repair insulation coatings applied to main pipelines (without taking them out of operation) in increasing the durability of these pipelines. As a specific feature of this method, we can mention the retardation of the subsequent propagation of surface fatigue cracks as a result of the artificial formation of the effect of their closure by filling the crack cavity with liquid epoxy resins. After solidification, it plays the role of a wedge decreasing the range of cyclic plastic strains near the crack tip, i.e., the mechanical driving force of fatigue crack growth. By using the obtained experimental results, we analyze the mechanical situation formed at the crack tip by using the outlined method of retardation of the crack growth.

Similar content being viewed by others

References

V. I. Makhnenko, V. S. But, and O. I. Oleinik, “Repair of main pipelines by welding without taking them out of service,” Probl. Prochn., No. 5, 86–100 (2009).

E. I. Kryzhanivs’kyi and H. M. Nykyforchyn, Hydrogen-Corrosion Degradation of Oil and Gas Pipelines and Its Prevention [in Ukrainian], Vol. 1: Fundamentals of the Evaluation of Degradation of Pipelines, Ivano-Frankivs’k National Technical University of Oil and Gas, Ivano-Frankivs’k (2011).

B. V. Kopei, V. V. Arkhirei, and T. P. Venhrynyuk, “Application of composite materials in the oil-producing complex,” Nauk. Visnyk IFNTUNH, No. 1, 68–76 (2010).

G. N. Nikiforchin, O. N. Romaniv, B. N. Andrusiv, et al., “A new method of increasing the cyclic crack resistance of structural parts,” Fiz.-Khim. Mekh. Mater., 21, No. 2, 92–93 (1985); English translation: Mater. Sci., 21, No. 2, 191–193 (1985).

O. N. Romaniv, G. N. Nikiforchin, and B. N. Andrusiv, “Effect of crack closure and evaluation of the cyclic crack resistance of constructional alloys,” Fiz.-Khim. Mekh. Mater., 19, No. 3, 47–61 (1983); English translation: Mater. Sci., 19, No. 3, 212–225 (1983).

RD 50–345–82. Methodical Recommendations. Strength Analyses and Tests in Machine Building. Methods for Mechanical Testing of Metals. Determination of the Characteristics of Crack Resistance (Fracture Toughness) under Cyclic Loading [in Russian], Izd. Standartov, Moscow (1983).

O. Z. Student, P. Cichosz, and J. Szymkowski, “Correlation between the fracture toughness and fatigue threshold of hightemperature degraded steel,” Fiz.-Khim. Mekh. Mater., 35, No. 6, 37–42 (1999); English translation: Mater. Sci., 35, No. 6, 796–801 (1999).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Fizyko-Khimichna Mekhanika Materialiv, Vol. 48, No. 6, pp. 45–48, November–December, 2012.

Rights and permissions

About this article

Cite this article

Venhrynyuk, T.P. Fatigue crack retardation by the application of repair coatings to gas pipelines under pressure. Mater Sci 48, 739–742 (2013). https://doi.org/10.1007/s11003-013-9562-x

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11003-013-9562-x