We have studied the tribological properties of VT14 titanium alloy with carbonitride coatings formed by the contact and noncontact method and binary (oxide and nitride) coatings. In the case of the contact method, specimens are saturated in a graphite backfill, and in the case of the noncontact method, specimens are located above it. We have investigated the wear resistance of a “titanium disk–bronze block” friction pair in AMH-10 hydraulic fluid under a load to 3 MPa on a friction path to 15 km. It has been established that coatings based on ternary interstitial compounds (titanium carbonitrides) provide a higher wear resistance than that of coatings based on binary interstitial compounds (titanium nitrides and oxides).

Similar content being viewed by others

References

A. I. Khorev and M. A. Khorev, “Titanium alloys: use and prospects of development,” Titan, No. 1 (16), 40–53 (2005).

M. Geetha, A. K. Singh, R. Asokamani, and A. K. Gogia, “Ti based biomaterials, the ultimate choice for orthopaedic implants—a review,” Prog. Mater. Sci., 54, 397–425 (2009).

N. F. Anoshkin, “State-of-the-art and further development of Ti-based materials,” in: Fundamental Problems of the Russian Metallurgy at the Beginning of the 20th Century [in Russian], Vol. 2, RAEN, Moscow (1998), pp. 195–258.

H. Dong and T. Bell, “Surface engineering of titanium: an-overview,” in: Ti-2003 Science and Technology, Proc. of the 10th World Conf. on Titanium Held at the CCH-Congress Center (July 13–18, 2003, Hamburg, Germany) Hamburg, Germany (2003), pp. 25–34.

T. Bell, W. Bergman, J. Lanagan, et al., “Surface engineering of titanium with nitrogen,” Surf. Eng., 2, 133–143 (1986).

L. Liu, Surface Hardening of Titanium Alloys by Gas Phase Nitridation under Kinetic Control, Dissertation, Case Western Reserve Univ. (2005).

B. A. Kolachev, V. I. Elagin, and V. A. Livanov, Physical Metallurgy and Heat Treatment of Metals and Alloys [in Russian], Moscow Institute of Steel and Alloys, Moscow (1999).

T. Bell, P. H. Morton, and A. Bloyce, “Surface engineering of titanium and titanium alloys,” Mater. Sci. Eng., A 184, 835–851 (1994).

L. Karlsson, Arc Evaporated Titanium Carbonitride Coatings, Dissertation, Linkoping Univ. (1999).

V. M. Fedirko, I. M. Pohrelyuk, and O. I. Yas’kiv, Thermodiffusion Multicomponent Saturation of Titanium Alloys [in Ukrainian], Naukova Dumka, Kyiv (2009).

V. N. Fedirko, I. N. Pogrelyuk, O. I. Yas’kiv, and S. V. Gurin, “Formation of functional coatings in multicomponent saturation of titanium by interstitial elements,” Titan, No. 1(20), 52–58 (2007).

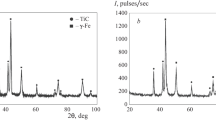

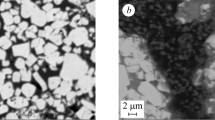

O. I. Yas’kiv, “Evolution of the phase composition of coatings in the course of thermodiffusion noncontact carbonitriding of titanium,” Fiz.-Khim. Mekh. Mater., 44, No. 4, 114–120 (2008), English translation: Mater. Sci., 44, No. 4, 594–601 (2008).

O. I. Yas’kiv, “Surface hardening of titanium by noncontact thermodiffusion carbonitriding,” Fiz.-Khim. Mekh. Mater., 44, No. 5, 63–68 (2008), English translation: Mater. Sci., 44, No. 5, 659–664 (2008).

G. V. Zemskov and R. L. Kogan, Multicomponent Diffusion Saturation of Metals and Alloys [in Russian], Metallurgiya, Moscow (1978).

A. Ya. Kulik, Yu. N. Presman, and L. S. Lyakhovich, “Diffusion carbonitriding of titanium,” in Protective Coatings on Metals [in Russian], Issue 8, Naukova Dumka, Kiev (1974), pp. 104–106.

W. Kraus and G. Nolze, “A program for the representation and manipulation of crystal structures and calculation of the resulting X-ray powder patterns,” J. Appl. Cryst., 29, 301–303 (1996)

Powder Diffraction File 1974. Search Manual Alphabetical Listing and Search Section of Frequently Encountered Phases. Inorganic, Philadelphia (1974).

Yu. N. Vil’k and I. N. Danisina, “Structural parameters and X-ray and pycnometric densities of titanium carbonitride in its homogeneity range,” Poroshk. Metall., No. 12 (168), 42–47 (1976), English translation: Powder Metall. Met. Ceram., 5, No. 12, 932–937 (1976).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Fizyko-Khimichna Mekhanika Materialiv, Vol. 47, No. 3, pp. 40–45, May–June, 2011.

Rights and permissions

About this article

Cite this article

Yas’kiv, O.I., Pohrelyuk, I.M., Sambors’kyi, O.V. et al. Tribological properties of carbonitride coatings formed on titanium by thermodiffusion carbonitriding. Mater Sci 47, 313–318 (2011). https://doi.org/10.1007/s11003-011-9398-1

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11003-011-9398-1