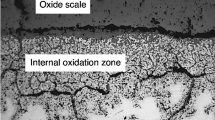

We study the corrosion, electrochemical, and corrosion–mechanical properties of deposited KKh30N6VSR cobalt-based, NKh15SR3 nickel-based, and Kh16N8S5 iron-based alloys in a standard NACE hydrogen-sulfide solution. It is shown that the deposited Kh16N8S5 iron-based alloy is unsuitable for these conditions due to its low corrosion resistance and susceptibility to hydrogen-induced cracking. The cobalt- and nickel-based alloys are suitable for the surfacing of the components of shutoff fittings of the oil-and-gas extraction equipment. However, as far as the “operating characteristics–cost” ratio is concerned, the nickel-based alloy outweighs the cobalt- based alloy.

Similar content being viewed by others

References

É. M. Gutman, V. G. Antonov, A. N. Isaev, V. V. Sidorenko, et al., “On the prolongation of the service life of shutoff and control fittings at the deposits of corrosive and aggressive natural gas,” Fiz.-Khim. Mekh. Mater., 26, No. 5, 122–123 (1990).

P. V. Gladkii, E. F. Perepletchikov, and I. A. Ryabtsev, Plasma Surfacing [in Russian], Ékotekhnologiya, Kiev (2007).

NACE Standard TM0177-90, Standard Test Method. Laboratory Testing of Metals for Resistance to Sulfide Stress-Corrosion Cracking in H2 S Environments, National Association of Corrosion Engineers (NACE), Houston (1990).

L. L. Schrier (editor), Corrosion Handbook, Butterworth, London (1976).

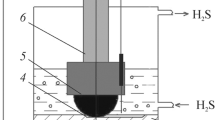

O. Radkevych, O. P’yasets’kyi, H. Krutsan, et al., “Autoclave for corrosion studies in media with admixtures of H2 S and CO2 / O,” in: Problems of Corrosion and Corrosion Protection of Structural Materials [in Ukrainian], Fiz.-Khim. Mekh. Mater., Special Issue 2 (2000), pp. 682–687.

NACE Standard TM0284-90, Standard Test Method. Evaluation of Pipeline Steels for Resistance to Stepwise Cracking, National Association of Corrosion Engineers (NACE), Houston (1990).

GOST 6032-2003 (Instead of GOST 6032-89). Interstate Standard, Corrosion-Resistant Steels and Alloys. Methods of Testing for the Resistance to Intercrystalline Corrosion [in Russian], Izd. Standartov, Minsk (2003).

A. I. Radkevich, M. D. Klapkiv, T. S. Dolotova, and I. I. Vasilenko, “Influence of the composition of hydrogen-sulfide-containing media on the crack-growth rate under cyclic loading,” Fiz.-Khim. Mekh. Mater., 20, No. 3, 29–32 (1984).

E. F. Perepletchikov and I. A. Ryabtsev, Plasma-Powder Surfacing in the Production of Fittings [in Russian], Ékotekhnologiya, Kiev (2007).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Fizyko-Khimichna Mekhanika Materialiv, Vol. 45, No. 5, pp. 119–123, September–October, 2009.

Rights and permissions

About this article

Cite this article

Chuchman, M.R., Ryabtsev, I.O., Krutsan, H.M. et al. Corrosion and stress-corrosion resistance of deposited metals in hydrogen-sulfide solutions. Mater Sci 45, 746–750 (2009). https://doi.org/10.1007/s11003-010-9239-7

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11003-010-9239-7